Submersible motor non-sensor temperature on-line monitoring device based on DC injection concept and monitoring method thereof

A technology of submersible motor and direct current injection, which is applied in the direction of thermometers, measuring devices, and electric devices using electric/magnetic components that are directly sensitive to heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

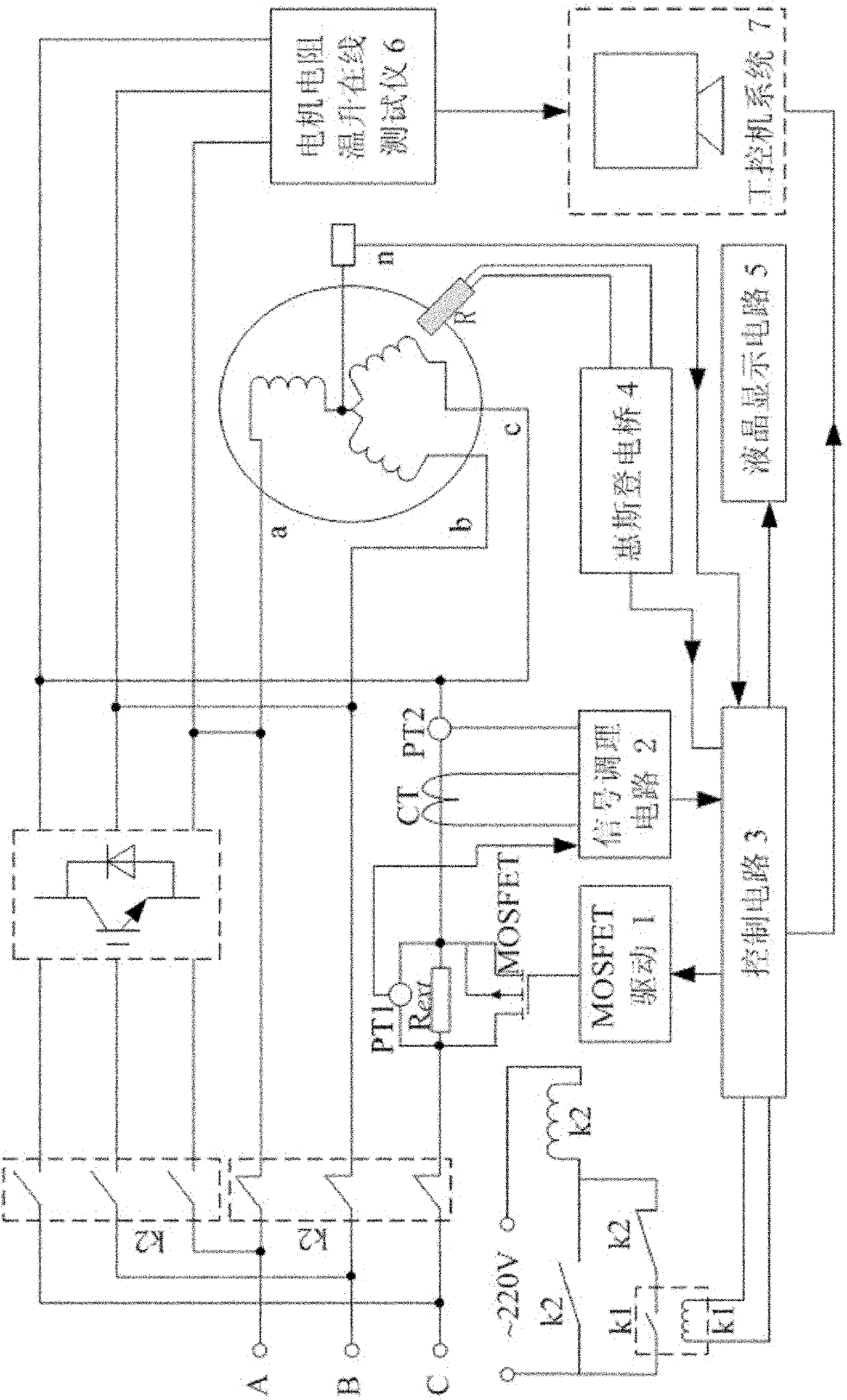

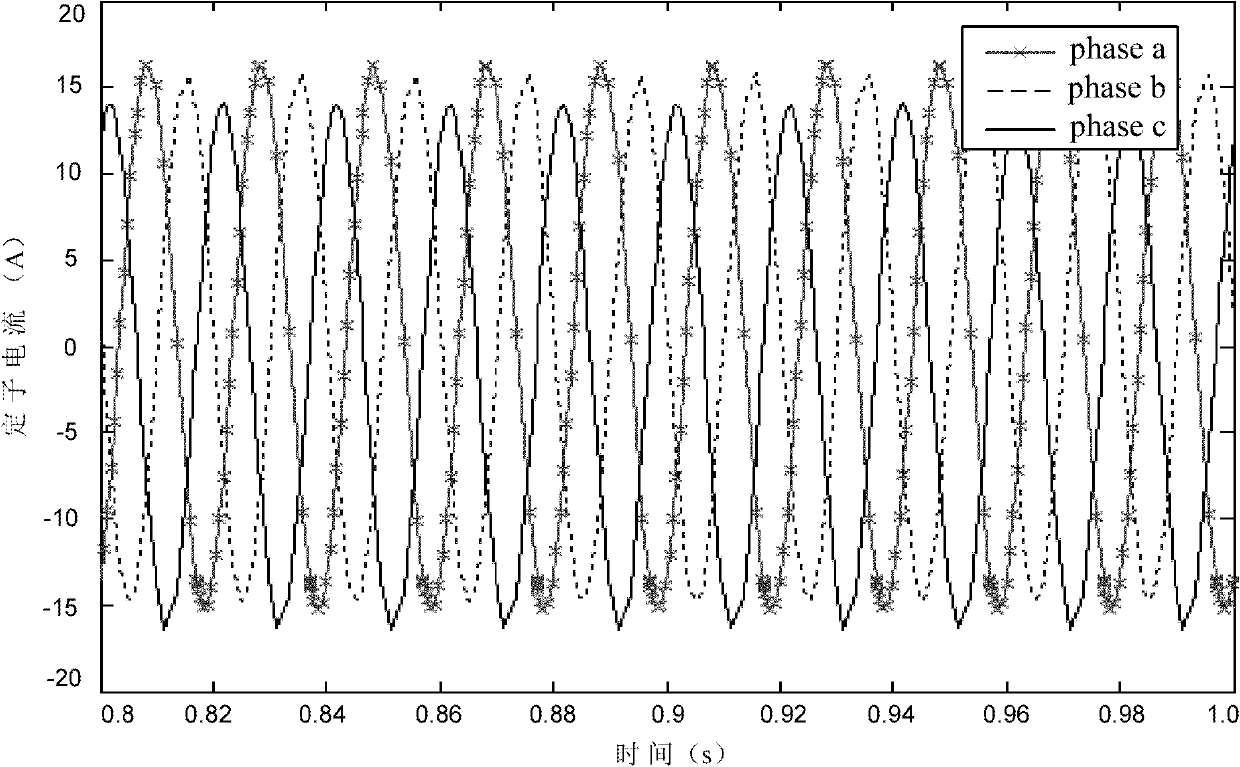

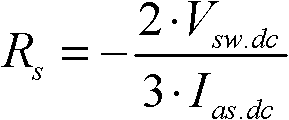

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is the submersible motor sensorless temperature on-line monitoring device based on DC injection idea, it includes sampling resistance R ext , field effect transistor MOSFET, field effect transistor driver 1, sampling resistance voltage transformer PT1, submersible motor stator phase current transformer CT, signal conditioning circuit 2 and control circuit 3; There is a sampling resistor R in series ext , and the sampling resistor R ext A sampling resistance voltage transformer PT1 and a field effect transistor MOSFET are connected in parallel at both ends of the two ends, and a current transformer CT is also arranged on one phase in the connection between the three-phase power supply and the motor, and the current signal output terminal of the current transformer CT and the sampling The voltage signal output terminal of the resistance voltage transformer PT1 is respectively co...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 Describe this embodiment. The difference between this embodiment and the specific embodiment is that it also includes a motor input voltage transformer PT2 for measuring the line voltage input by the motor. The motor input voltage transformer PT2 is connected in series between the three-phase power supply and the motor. Motor input for one phase in the wiring. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the first or second embodiment is that it also includes a liquid crystal display circuit 5 , and the data signal output end of the control circuit 3 is connected to the data signal input end of the liquid crystal display circuit 5 . Other compositions and connection modes are the same as those in Embodiment 1 or 2. It is used to display the stator current waveform diagram monitored in the DC injection mode of the submersible motor, and express it in a more intuitive form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com