Jumper board

A jumper board and terminal technology, applied in the field of jumper boards, can solve the problems of affecting the test effect, large damage to the test board, longer preparation time for new integrated circuit products, etc., to achieve long-term benefit savings, high test utilization, shortening The effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

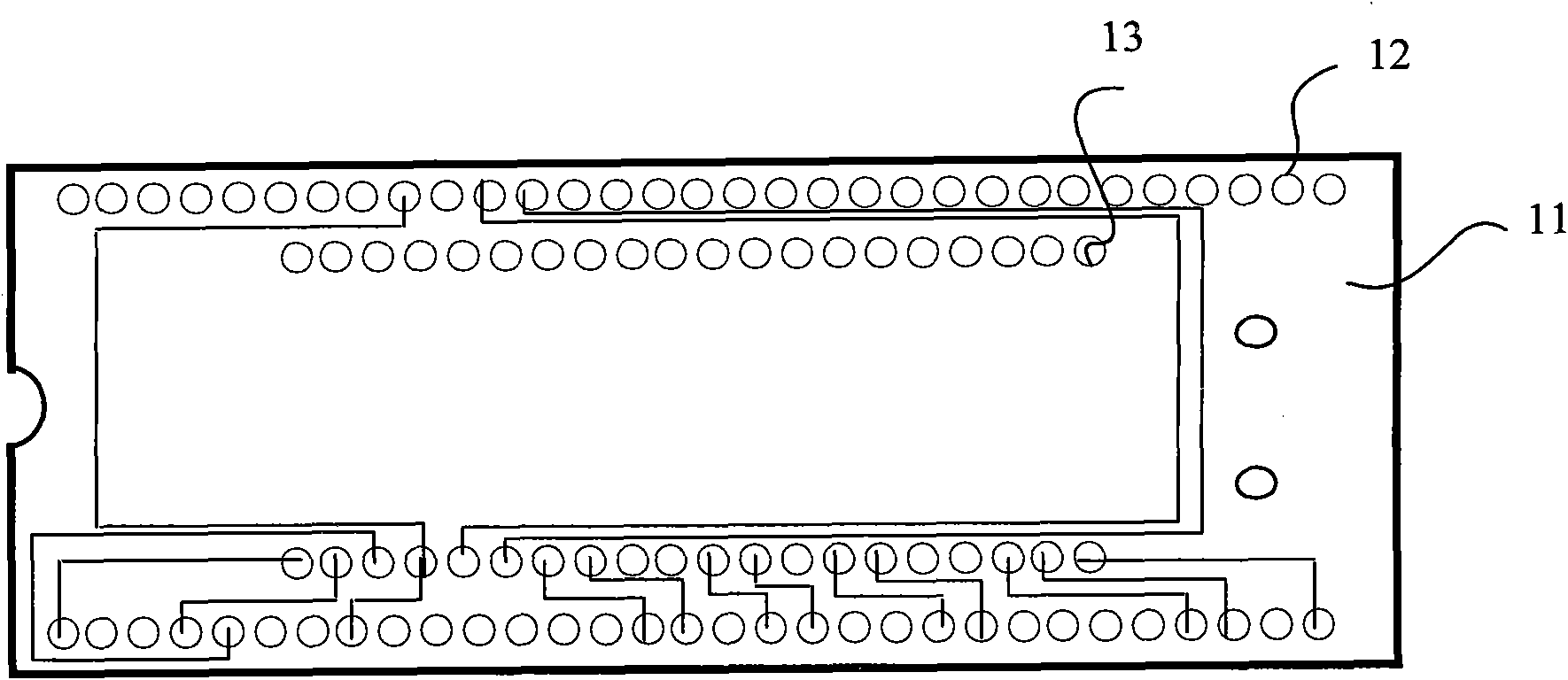

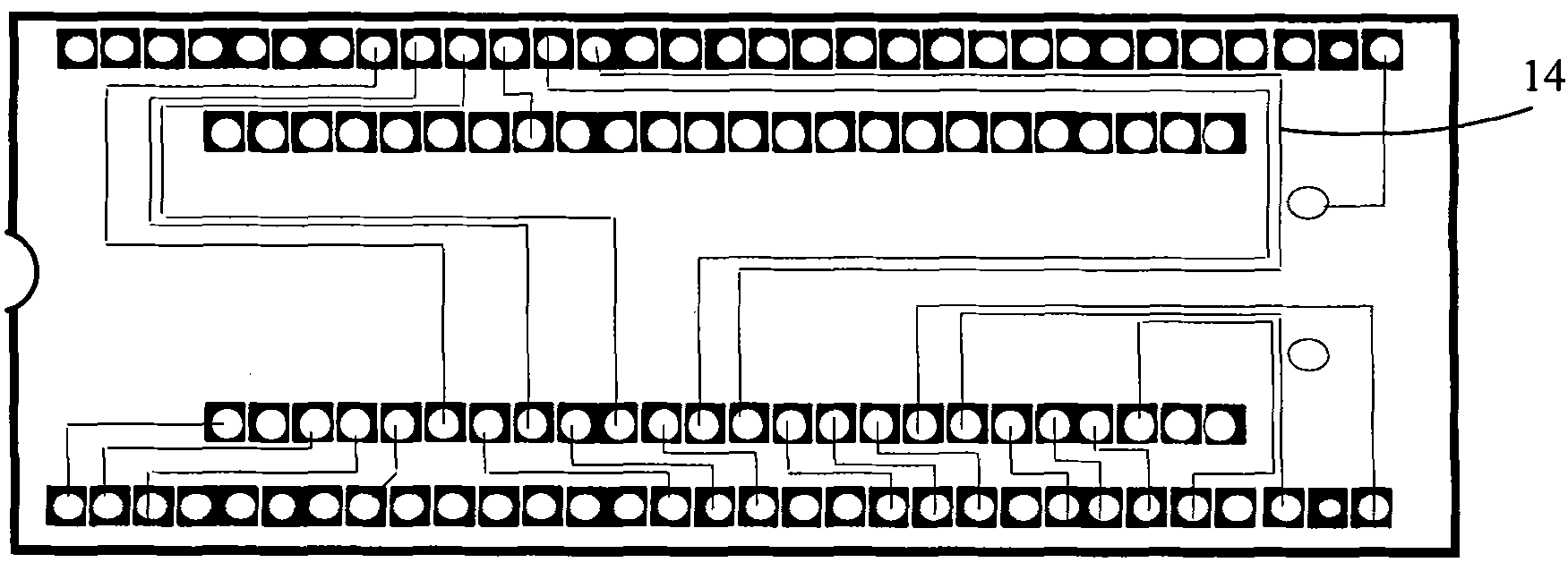

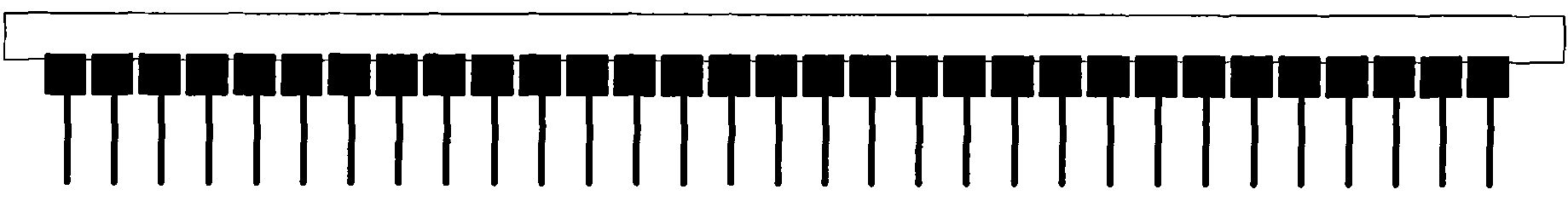

[0025] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] It has been mentioned in the background art that conventional jumper boards are suitable for testing a single integrated circuit product, and corresponding jumper boards need to be manufactured for different types of integrated circuit products to meet testing requirements.

[0027] The core idea of the present invention is that by using the multi-way switch in the switch chip to control the connection and shutdown between the signal terminal and the terminal on the jumper board, it is only necessary to program and control the multi-way switch for different types of integrated circuit products. state to realize the connection relationship between the signal terminal and the terminal to meet the test requirements.

[0028] Figure 5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com