Ultrathin three-lens imaging lens set

An imaging lens, three-piece technology, applied in the direction of optical components, optics, instruments, etc., can solve the problems of high lens eccentricity error requirements, low product yield, high production cost, etc., to reduce the number of lenses, reduce aberrations, reduce small angle effect

Inactive Publication Date: 2011-05-11

凤凰光学(上海)有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among the common three-piece lenses, the front aperture is the majority, and its advantage is that the telephoto ratio is small (the telephoto ratio (TL / f) is the ratio of the total length (TL) of the entire optical system to the focal length (f)), light incident The angle to the photosensitive element is small; the disadvantage is that the requirements for lens eccentricity error are high, and the processing is difficult

This type of lens has a low product yield rate and a relatively high production cost in the mass assembly process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0081] Table 1

[0082]

[0083] Table 2

[0084]

example 2

[0086] table 3

[0087]

[0088] Table 4

[0089]

example 3

[0091] table 5

[0092]

[0093] Table 6

[0094]

[0095] For each of the above examples, the main parameters satisfying the listed conditions are shown in the table below:

[0096] Table 7

[0097]

[0098] f / f 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

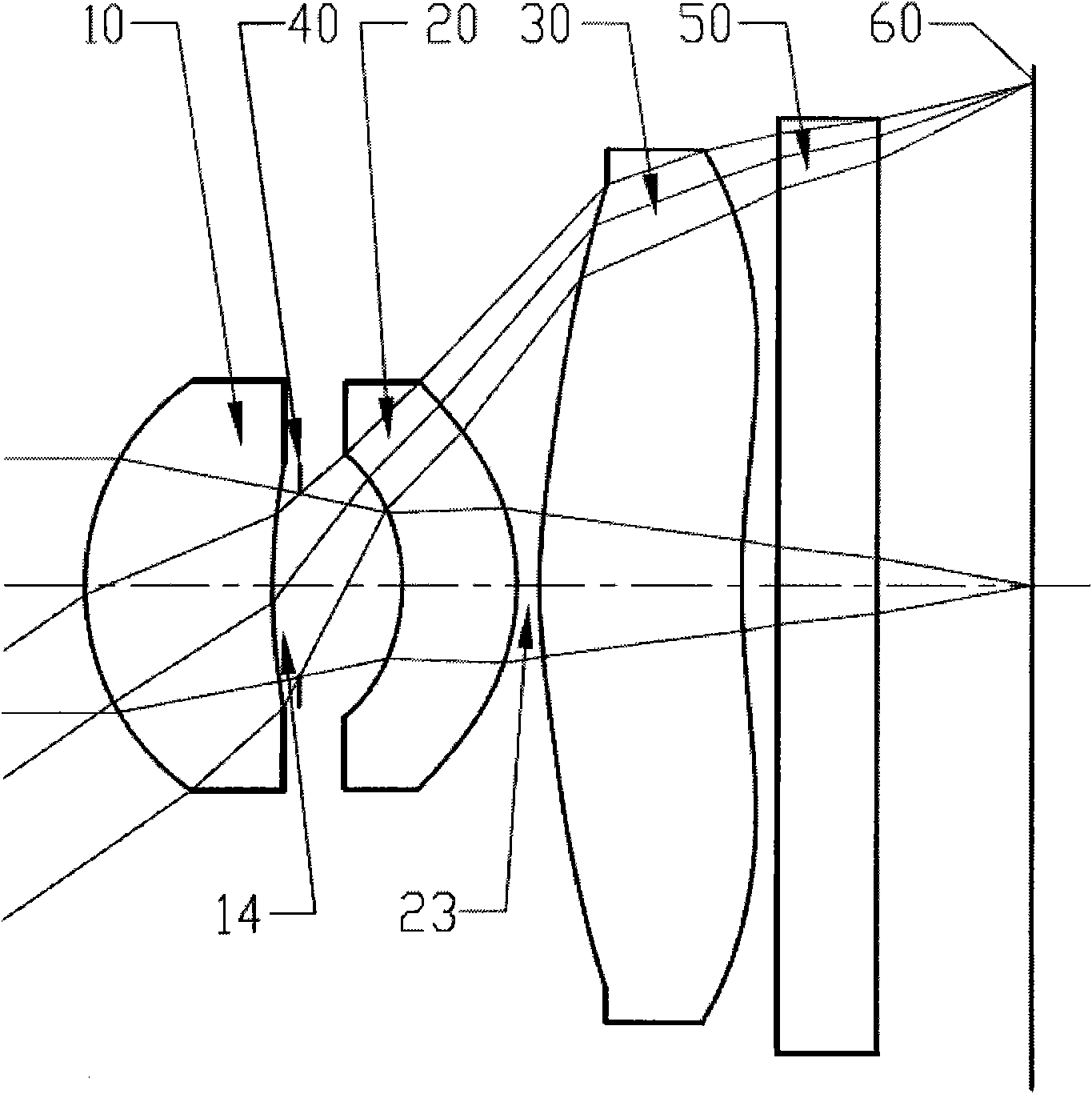

The invention relates to an ultrathin three-lens imaging lens set, in particular to an ultrathin imaging lens set applied to a photographing mobile phone lens and a notebook computer photographing lens. The imaging lens set consists of three lenses with refractive indexes and an open diaphragm; the first lens, the open diaphragm, the second lens and the third lens are arranged in turn from an object side to an image side, wherein the first lens is a positive lens, the front surface of the first lens is a convex surface, and the rear surface of the first lens is a concave surface; the second lens is a negative lens, the front surface of the second lens is a concave surface, and the rear surface of the second lens is a convex surface; and the third lens is a positive lens, the front surface of the third lens is a convex surface, and the rear surface of the third lens is a concave surface. Moreover, each surface of the first lens, the second lens and the third lens consists of a high-order non-spherical plastic lens so as to reduce the cost and meet the resolution requirement of a high-pixel photosensitive element.

Description

【Technical field】 [0001] The invention relates to an ultra-thin three-piece imaging lens group, in particular to an ultra-thin imaging lens group applied to camera lenses and notebook computer camera lenses. 【Background technique】 [0002] It is generally suitable for lenses with megapixels above 1.3 MEGA and below 3.0 MEGA, and most of them adopt a three-piece lens structure. Among the common three-piece lenses, the front aperture is the majority, and its advantage is that the telephoto ratio is small (the telephoto ratio (TL / f) is the ratio of the total length (TL) of the entire optical system to the focal length (f)), light incident The angle to the photosensitive element is small; the disadvantage is that the requirements for lens eccentricity error are high, and the processing is difficult. The yield rate of this type of lens is low in the process of mass assembly and production, and the production cost is relatively high. 【Content of invention】 [0003] The inventi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B13/00G02B13/18

Inventor 辛保云

Owner 凤凰光学(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com