Method for controlling cracking depth of cracking furnace in ethylene device

A cracking depth and ethylene device technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of limited scope of application, and achieve the effects of large changeable range, wide application and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment, further illustrate the present invention.

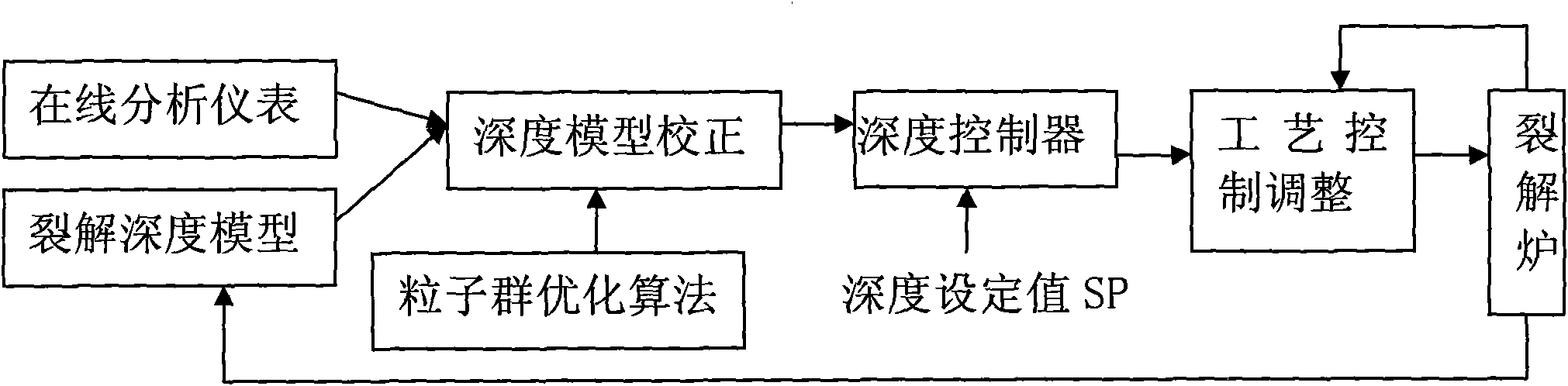

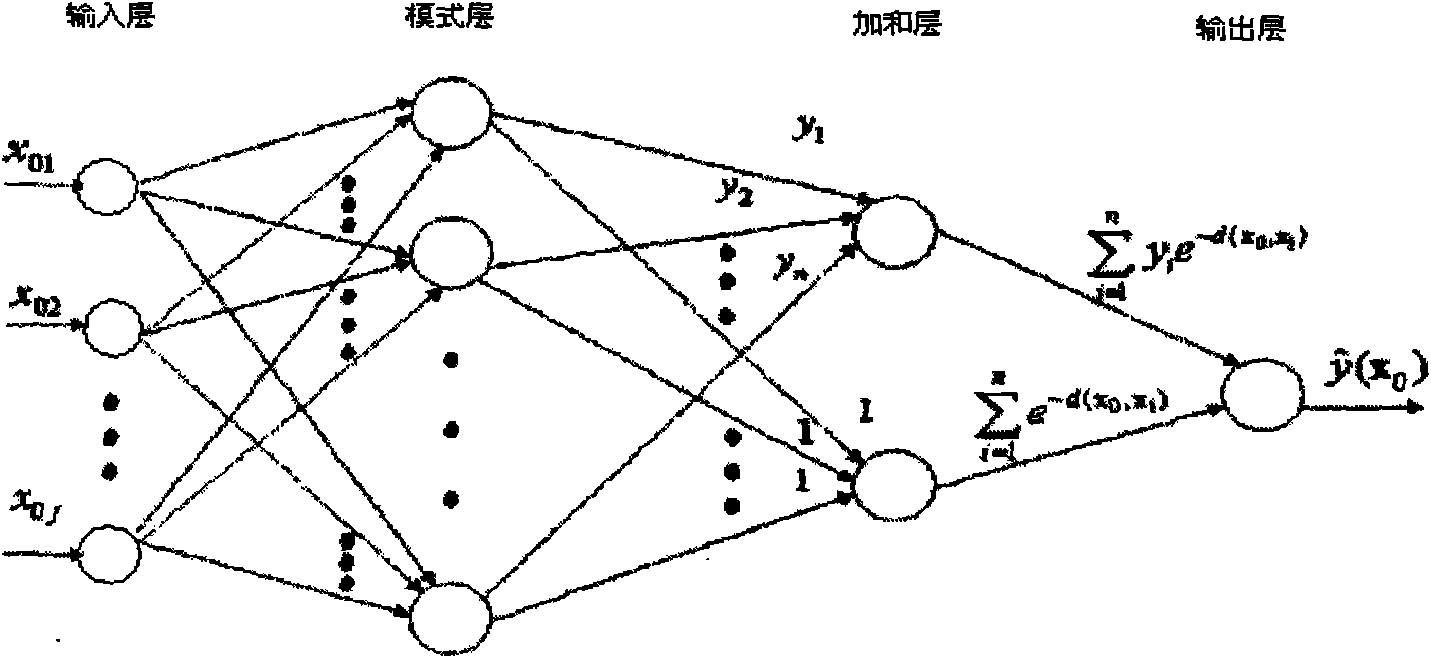

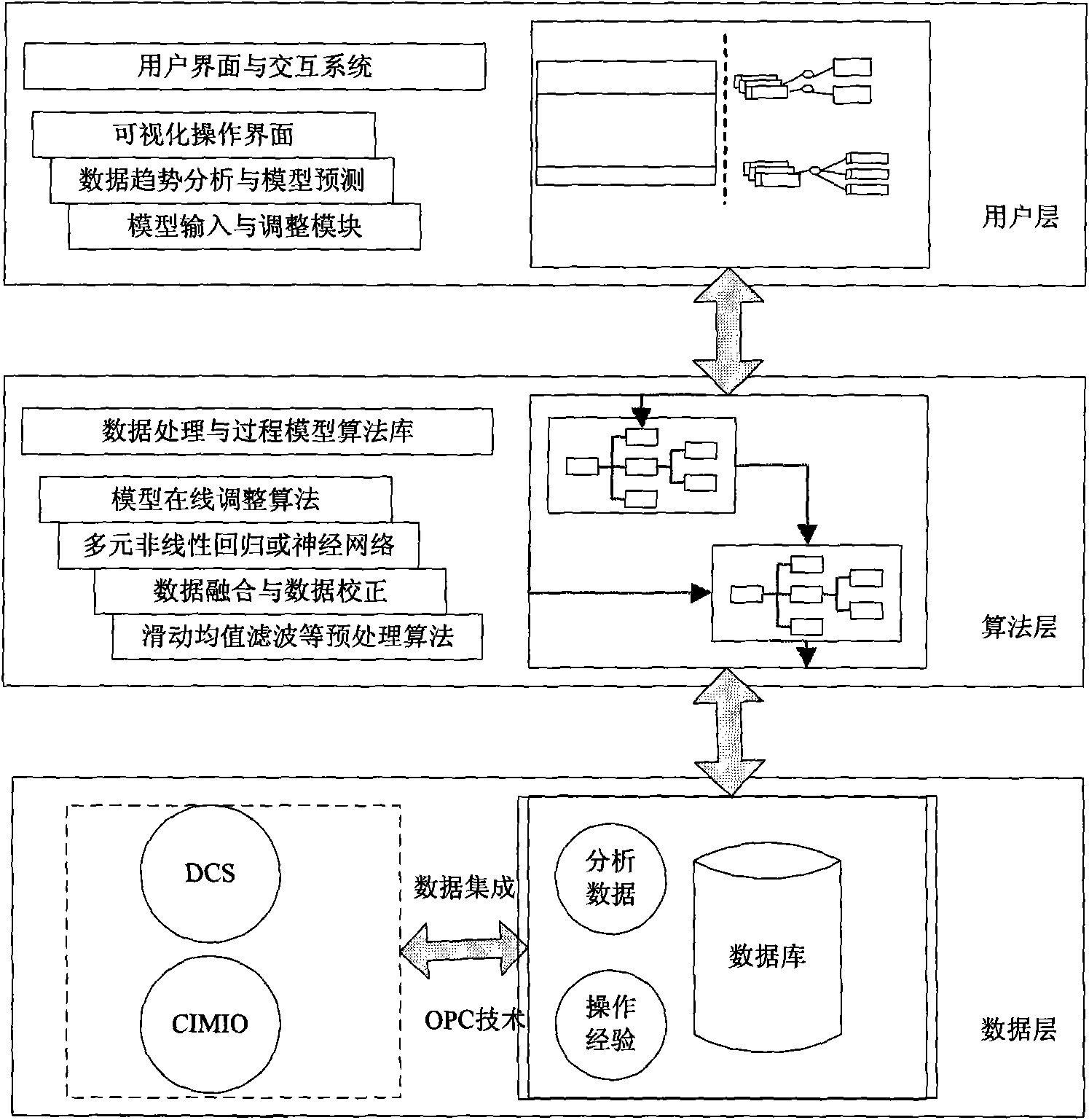

[0038] The method of the present invention is to set up a product yield prediction optimization model respectively for different cracking raw materials, and read the raw material feed rate, dilution steam volume and radiation section outlet temperature (COT) of the raw material properties and cracking furnace through the instrument control system Calculate the current cracking depth and compare it with the control set value to adjust the operating parameters so that the cracking depth is closer to the set value; or according to the physical properties of the raw material, calculate the operating process conditions when optimizing the target product distribution, so that the Operational parameters are adjusted to target values. The operating time and process operation parameters of the cracking furnace can be read in through the instrument control system, and the maximum tube wall temperatu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap