Method and device for detecting wafer surface defects

A detection method and defect technology, applied in the direction of measuring devices, optical devices, semiconductor/solid-state device testing/measurement, etc., can solve problems such as inaccurate positioning, inability to locate chips, unfavorable analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

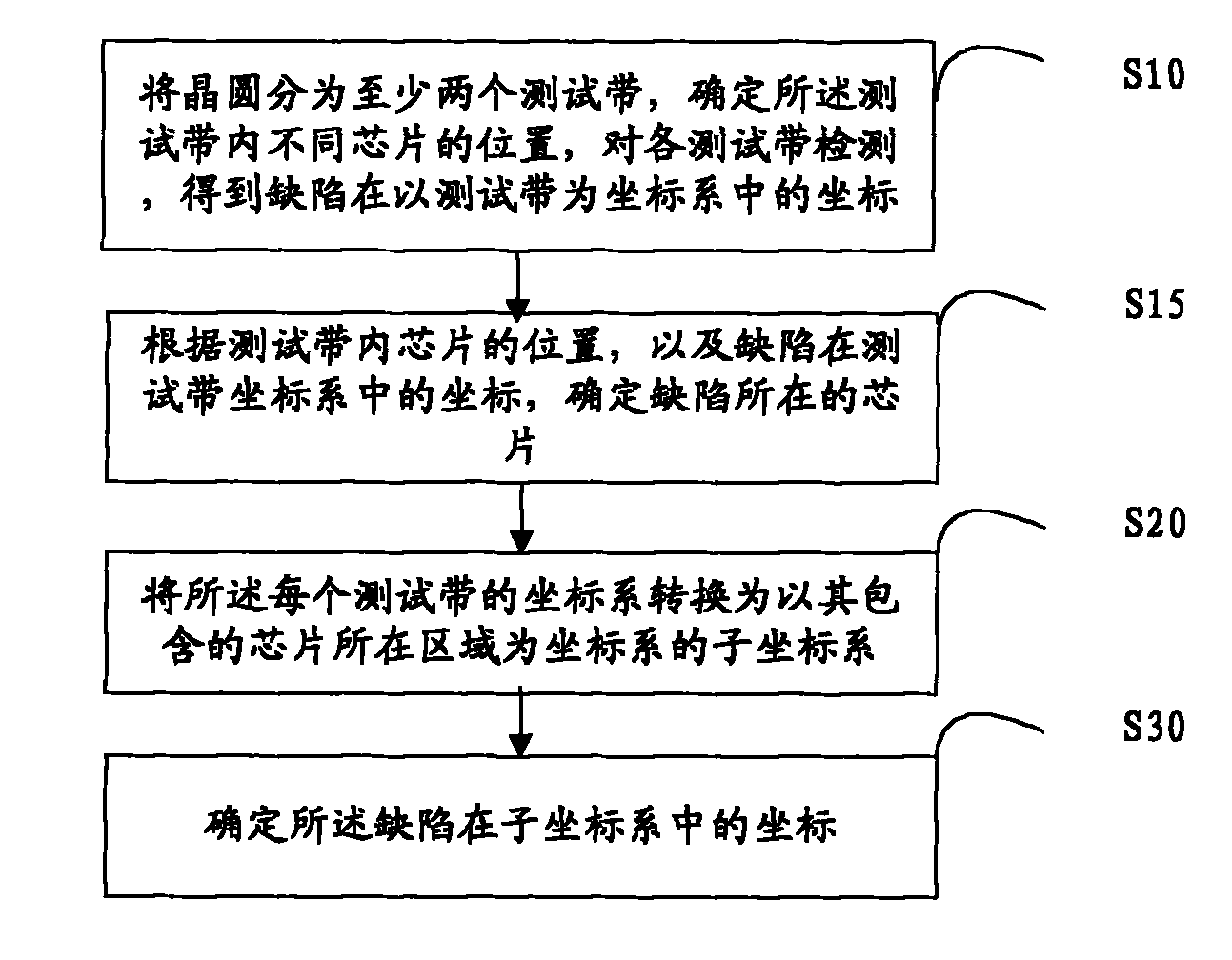

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

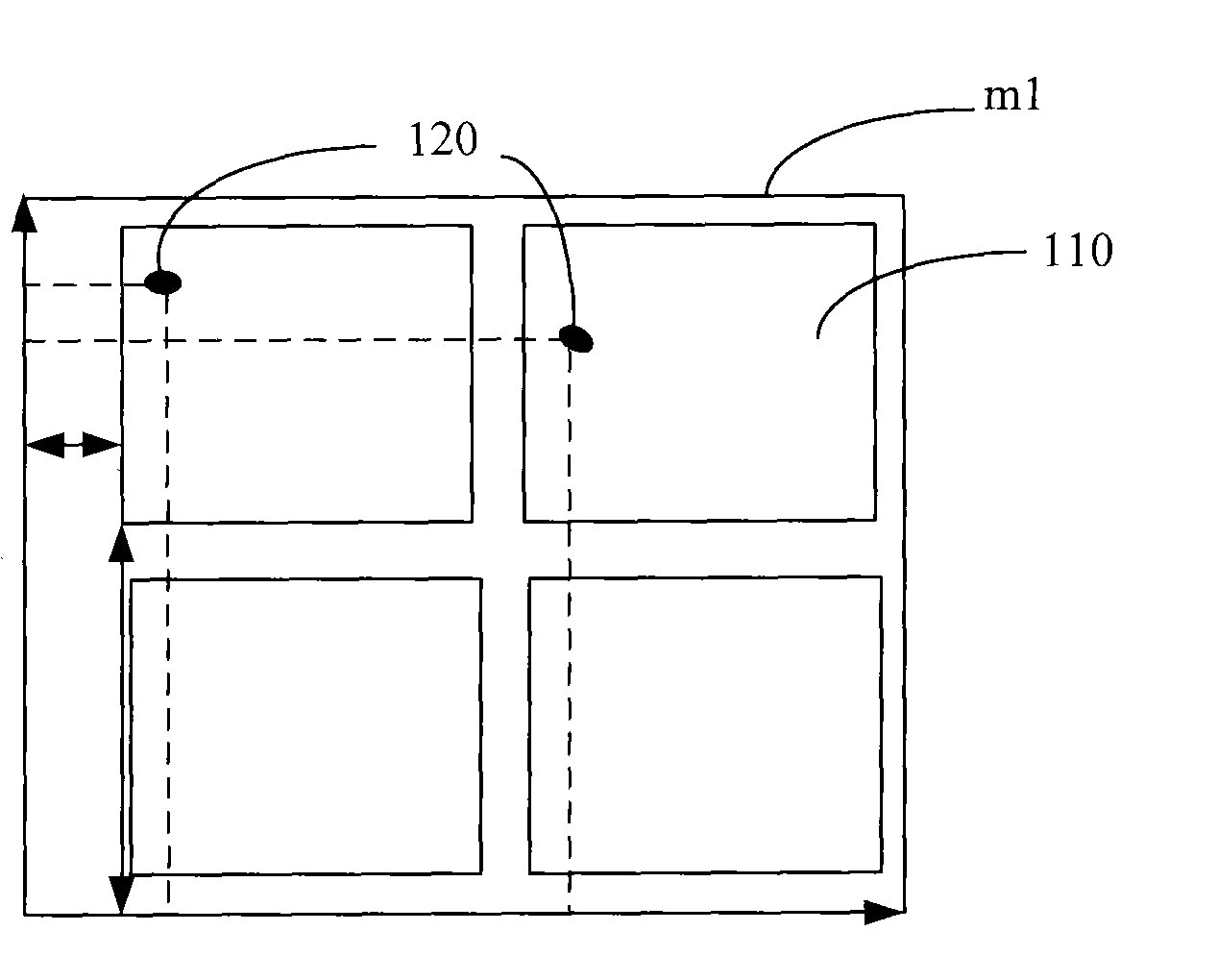

Embodiment Construction

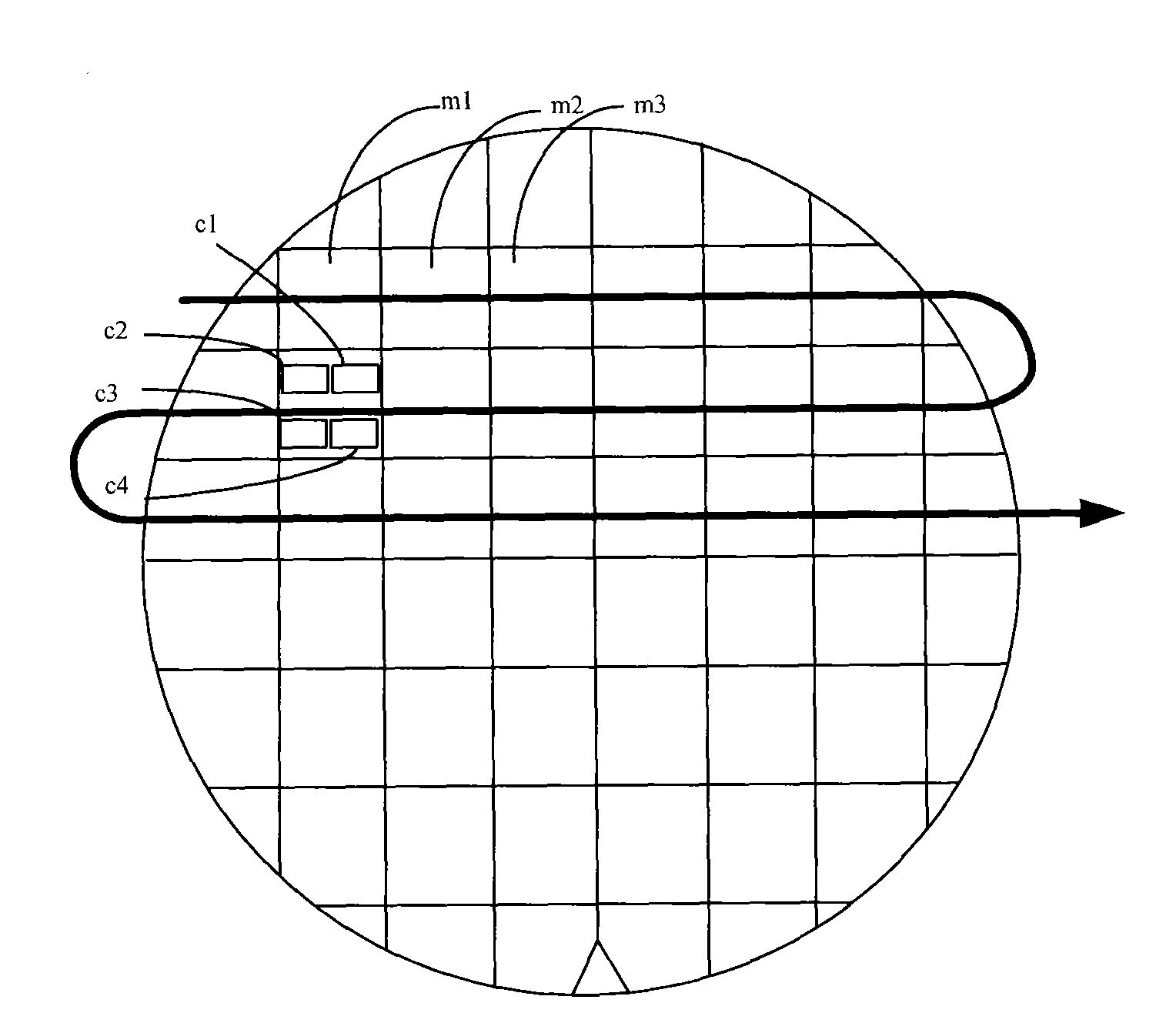

[0029] It can be seen from the background technology that an existing detection device for detecting defects on the surface of a wafer uses a test tape (die by die) comparison method to detect defects. However, the usual size of a test tape can be one chip (chip) The area where the chip is located or the area where multiple chips are located, or an exposure area (BLOCK), the result file generated by the detection corresponds to the defined test zone, so that the position of the defect in the test zone can be located. However, when the above-mentioned equipment is used for inspection, the size of the test strip should not be less than 2mm×2mm. Therefore, when the size of the chip is smaller than 2mm, one test strip will include the area where multiple chips are located, so that the equipment cannot accurately locate the defect. The position in the chip, so that the chip with the defect cannot be located, so it is not conducive to analyzing the cause of the defect.

[0030] Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com