Heating device and manufacturing method thereof

A heating device and heating element technology, applied in the direction of heating element materials, ohmic resistance heating, electric heating devices, etc., can solve the problems of insufficient carbon fiber strength, easy to break, and insufficient durability of heating elements, etc., to achieve good electrical conductivity and heat dissipation Stability, not easy to break, high electrothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

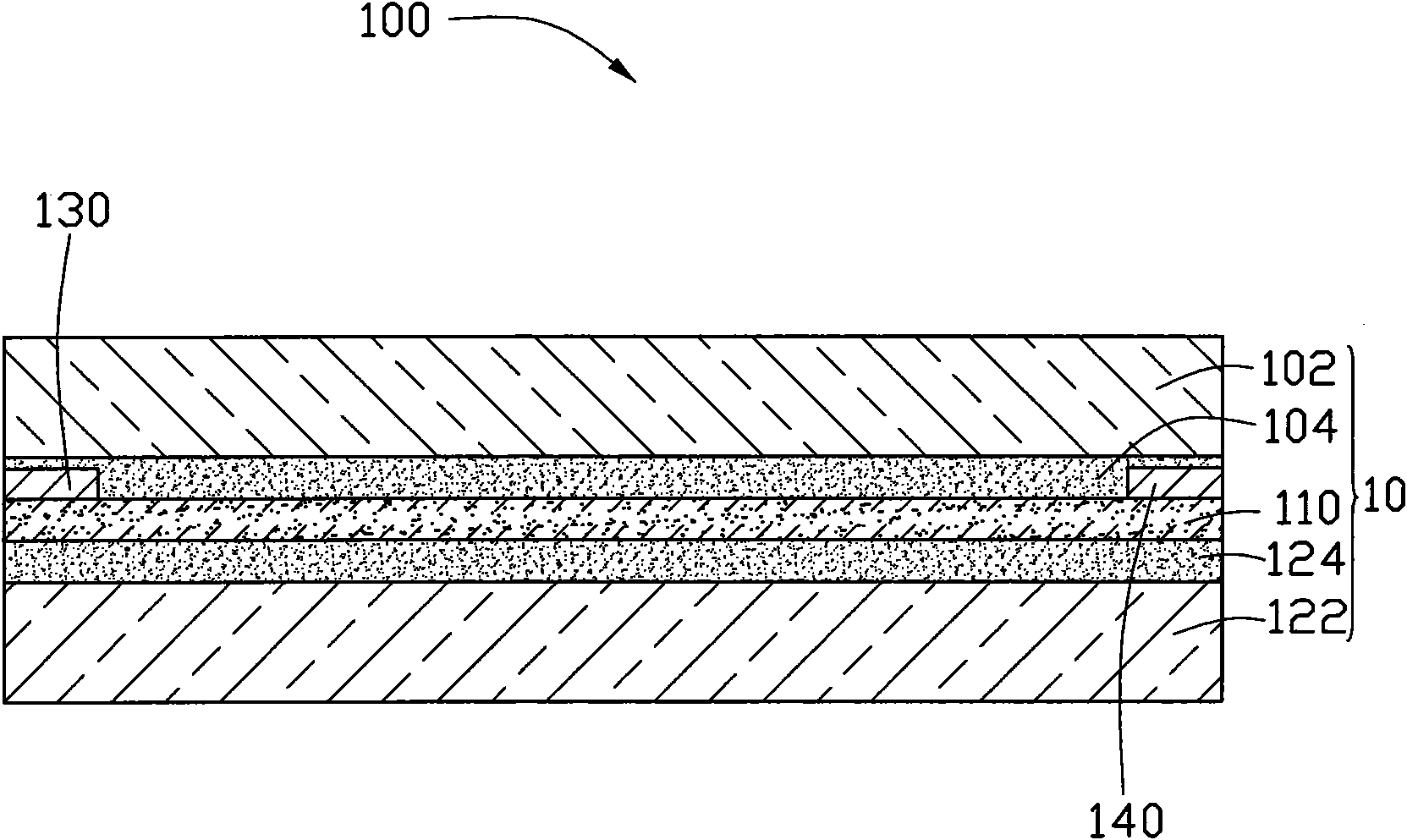

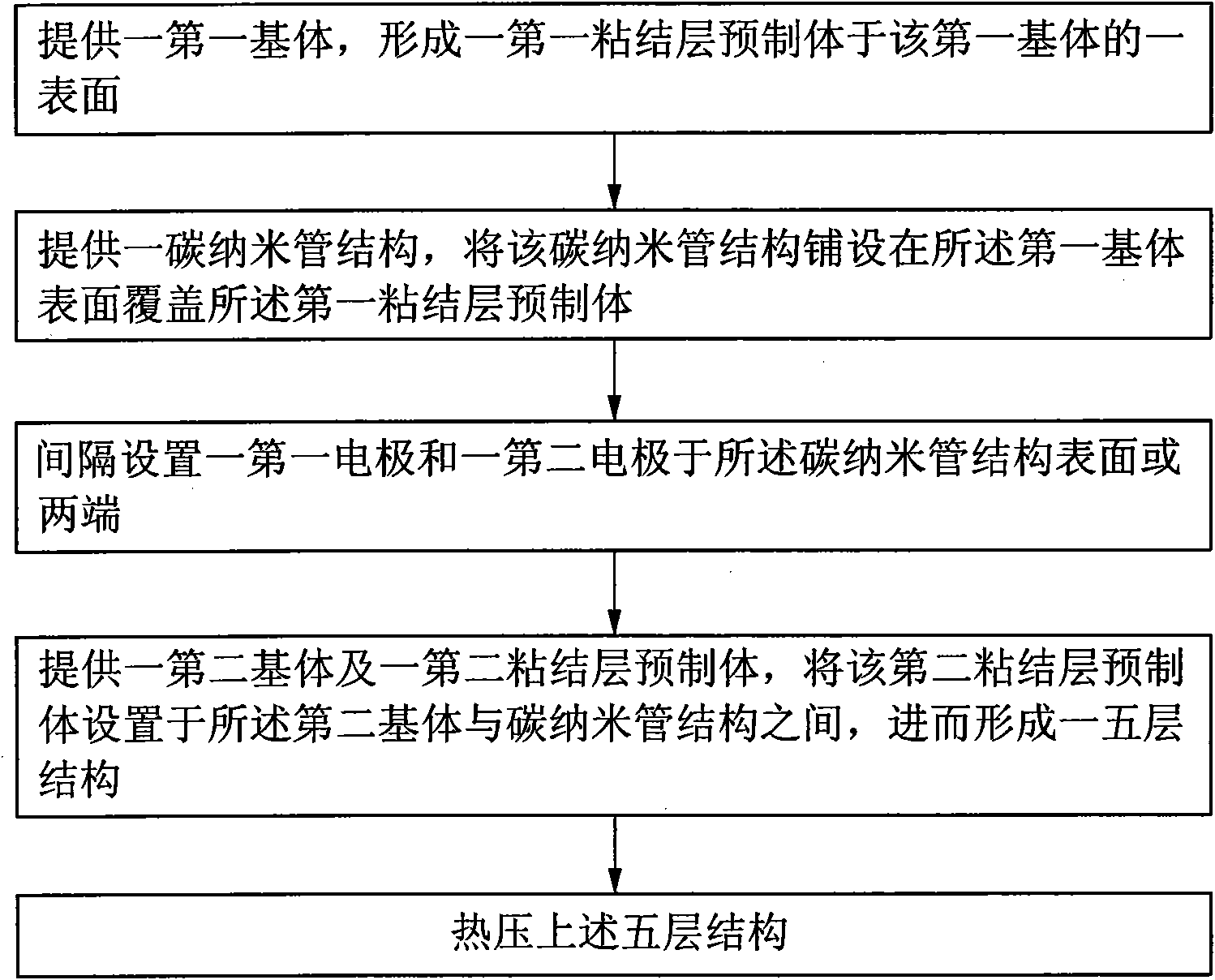

[0031] see image 3 , the present invention provides a method for preparing the above-mentioned heating device 100, the method comprising the following steps:

[0032] Step 1: providing a first base body 102 and forming a first adhesive layer preform on a surface of the first base body 102 .

[0033] When the material of the first adhesive layer preform is a hot melt adhesive film, the first adhesive layer preform can be prepared by directly laying a hot melt adhesive film on the surface of the first base 102 . When the material of the first adhesive layer preform is hot melt adhesive powder, the hot melt adhesive powder can be sprinkled on the surface of the first substrate 102 to form a first adhesive layer preform. Optionally, an infrared reflection layer may be formed on a surface of the first substrate 102 by sputtering or other methods. The infrared reflection layer may be formed between the first base body 102 and the first adhesive layer preform or disposed on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com