Outdoor aluminum storage box

A technology for storage boxes and components, applied in the direction of metal casings, etc., can solve the problems of external components such as depression, intrusion, and poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

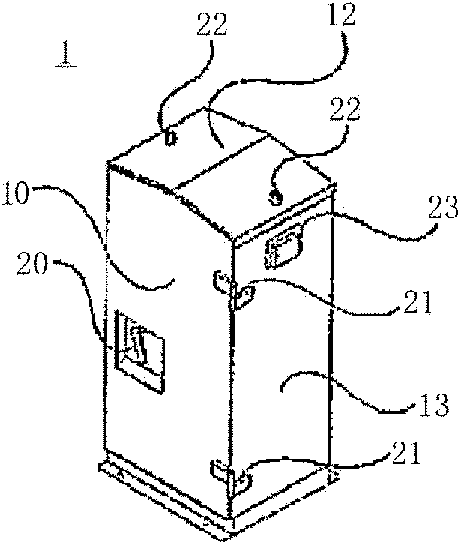

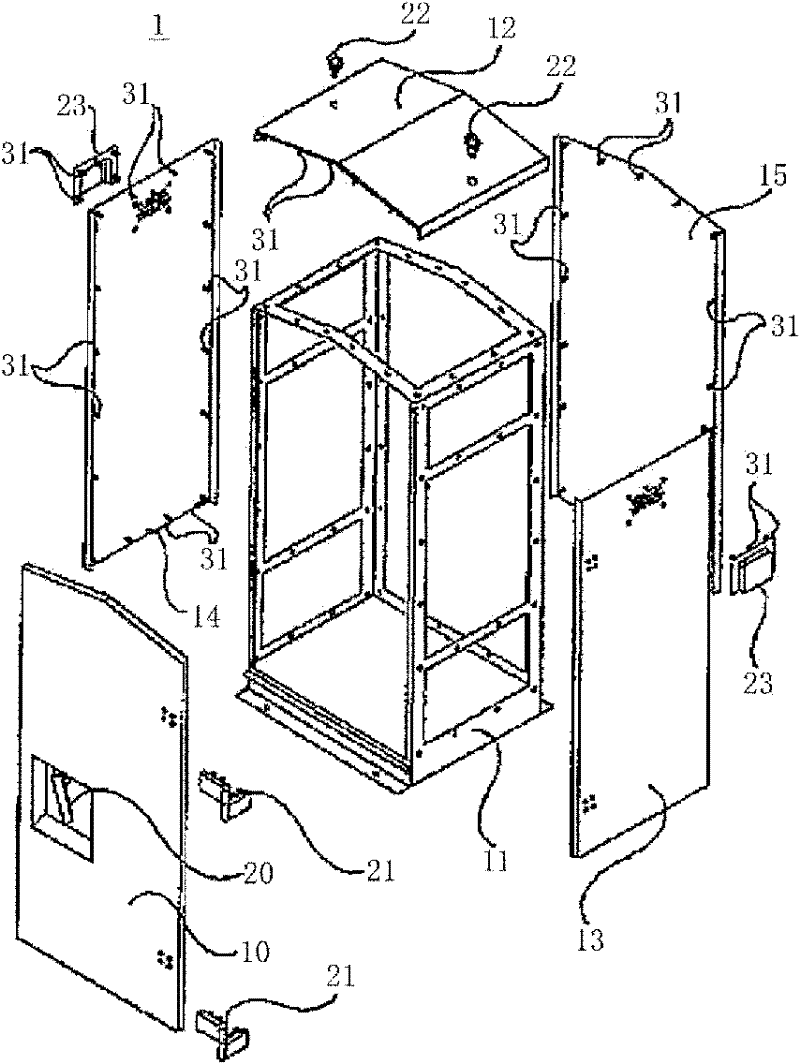

[0047] The appearance and function of outdoor aluminum storage box 1:

[0048] figure 1 The shown outdoor aluminum storage box 1 is roughly rectangular in shape as a whole, and its external dimensions are about 0.5m wide, about 1m high, and about 0.5m deep. The storage box 1 has many types, with different widths, The height and depth are different in size. There is an aluminum door panel 10 on the front side, which is attached to the aluminum right side panel 13 through a hinge 21. When the lever handle 20 installed on the aluminum door panel 10 is rotated in the counterclockwise direction, the lock mechanism (not shown) located inside the aluminum door panel 10 operates in conjunction with the lever handle 20 to make the aluminum The fixing of the door panel 10 is released, and the aluminum door panel 10 can be opened.

[0049] When the aluminum door panel 10 is opened, it can be seen that there is a storage space inside the aluminum storage box 1 for outdoor use. For the purpo...

Embodiment 2

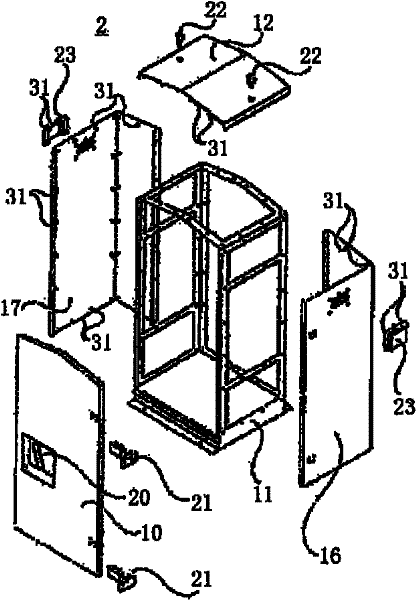

[0072] The appearance and function of outdoor aluminum storage box 2:

[0073] The appearance and function of the outdoor aluminum storage box 2 are the same as those of the outdoor aluminum storage box 1 of the first embodiment, so the description is omitted. In addition, the surface of the outdoor aluminum storage box 2 has been treated with alumina.

[0074] The main parts of outdoor aluminum storage box 2:

[0075] image 3 It is an exploded view of the outdoor aluminum storage box 2. The main parts are aluminum door panel 10, aluminum frame member 11, and multiple aluminum panels covering the aluminum frame member 11. These aluminum panels are aluminum roof panel 12 and L-shaped aluminum right side panel 16. Or L-shaped aluminum left side plate 17.

[0076] Aluminum door panels and aluminum roof panels:

[0077] The aluminum door panel 10 and the aluminum roof panel 12 are the same as in the first embodiment, so the same symbols are added to omit the description.

[0078] Aluminu...

Embodiment 3

[0089] The appearance and function of outdoor aluminum storage box:

[0090] The appearance and function of the outdoor aluminum storage box 3 are the same as those of the outdoor aluminum storage box 1 of the first embodiment, so the description is omitted. In addition, the surface of the outdoor aluminum storage box 3 has been treated with alumina.

[0091] The main parts of outdoor aluminum storage box 3:

[0092] Figure 4 It is an exploded view of the aluminum storage box 3 for outdoor use. The main parts are an aluminum door panel 10, an aluminum frame member 11, and a plurality of aluminum panels covering the aluminum frame member 11. These aluminum panels are aluminum roof panels 12 or U-shaped aluminum side panels 18.

[0093] Aluminum door panels and aluminum roof panels:

[0094] The aluminum door panel 10 and the aluminum roof panel 12 are the same as those in the first embodiment, so the same symbols are attached to omit the description.

[0095] Aluminum skeleton parts:

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap