Single-sided tape tension control mechanism

A technology of tension control mechanism and tape, which is applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of inconsistent length of copper foil, increase of defective rate, and uneven viscosity of single-sided tape, so as to solve uneven tension, The effect of increasing tension stability, reducing a large number of defective products and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

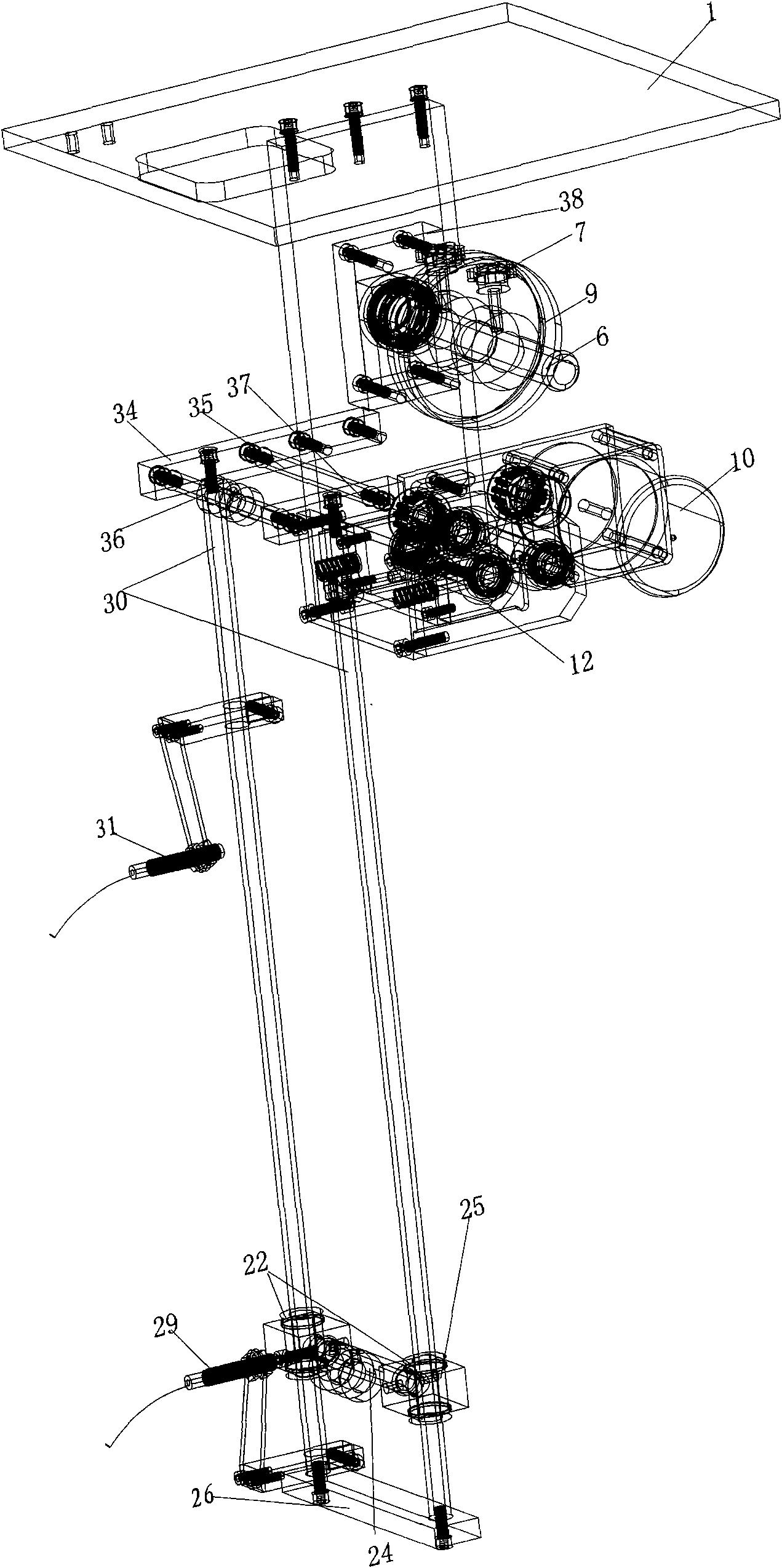

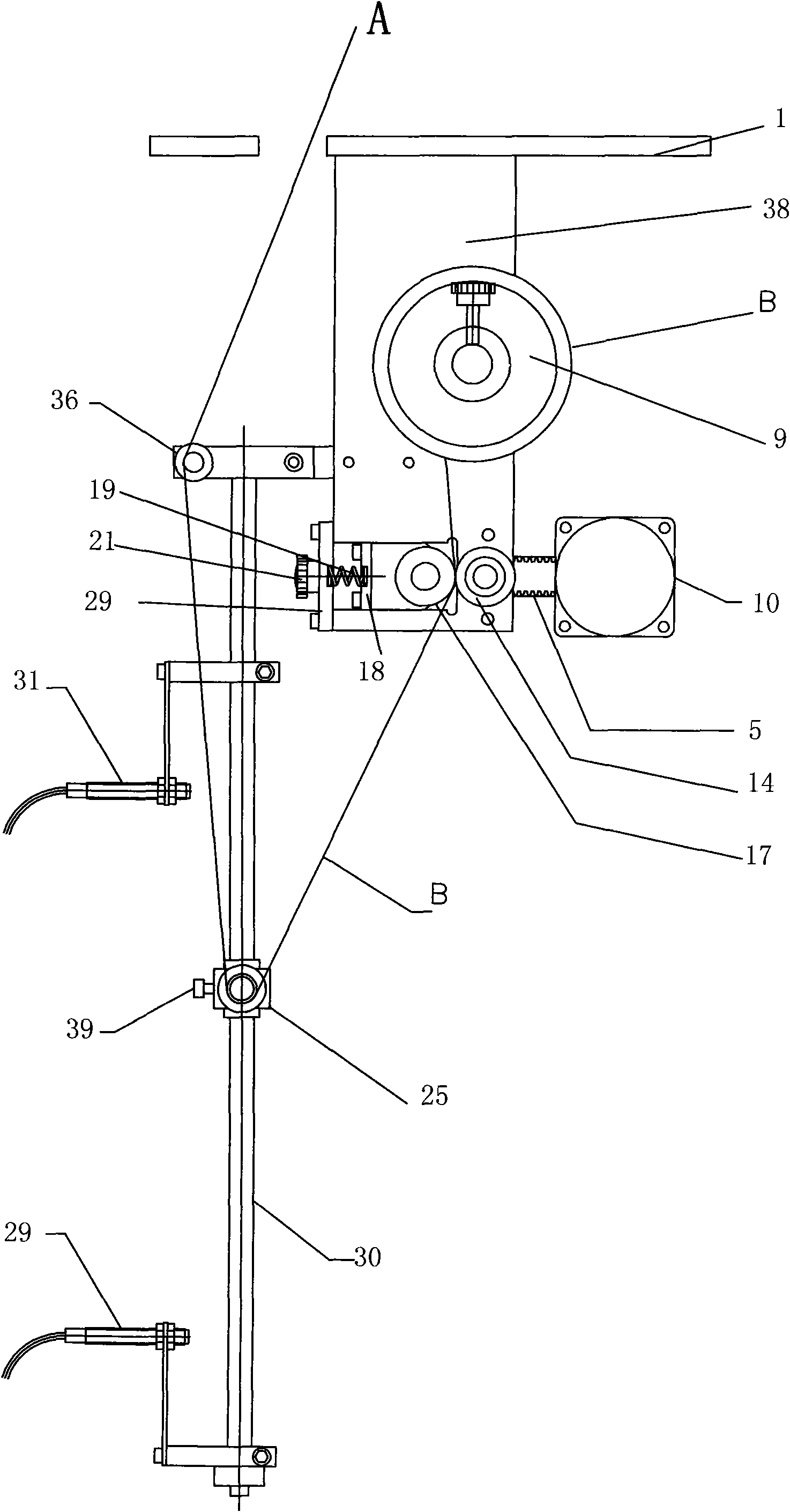

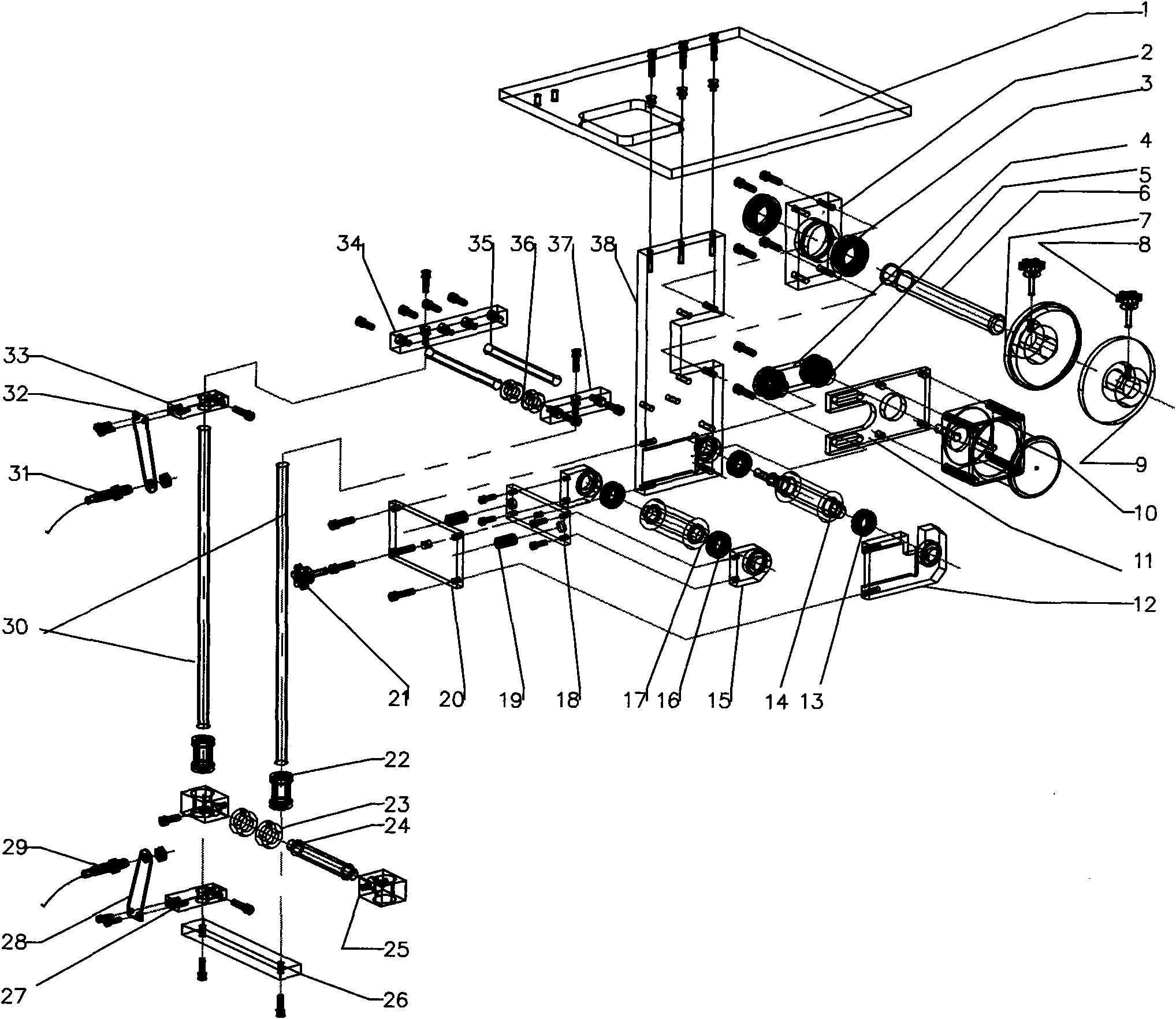

[0009] refer to figure 1 , figure 2 , image 3 As shown, the composition of the mechanism and the functions of the accessories: the mechanism is composed of several accessories and a number of screws. The motor needs to be driven by the synchronous wheel 4 and the synchronous belt 5. Put the tape to fix the shaft 6, the single-sided tape to fix the disc 7, 9, and the rubber ring for the bearing. The locking screw 8 is locked after the tape is positioned. Just tighten the screw 8, reducer motor 10, this motor 10 drives the silicone roller 14 and Unisex rubber roller 17 through the synchronous wheel 4 and the synchronous belt 5 to send out the single-sided tape, and the motor fixing plate 11 is used for fixing and installing the reduction motor 10 , The rubber roller fixes the side plate 12, which plays the role of fixing and installing the rubber wheel assembly, the silicone roller 14 (high-density silicone hardness is 80 degrees, and can withstand high temperature 200-300 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com