Pneumatic propulsion device of welding fixture positioning pin for automobile body and work method thereof

A technology of automobile body and propulsion device, applied in auxiliary devices, manufacturing tools, welding equipment and other directions, can solve the problems of time-consuming and laborious operation, insufficient installation space, large space occupation, etc., and achieves easy installation and operation, low cost, The effect of stable working condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

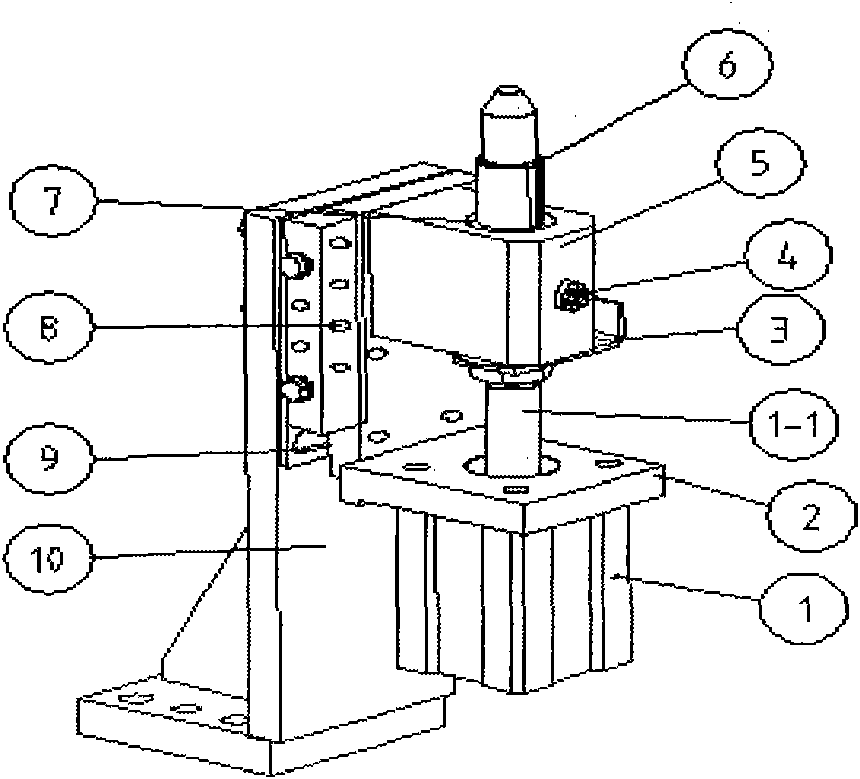

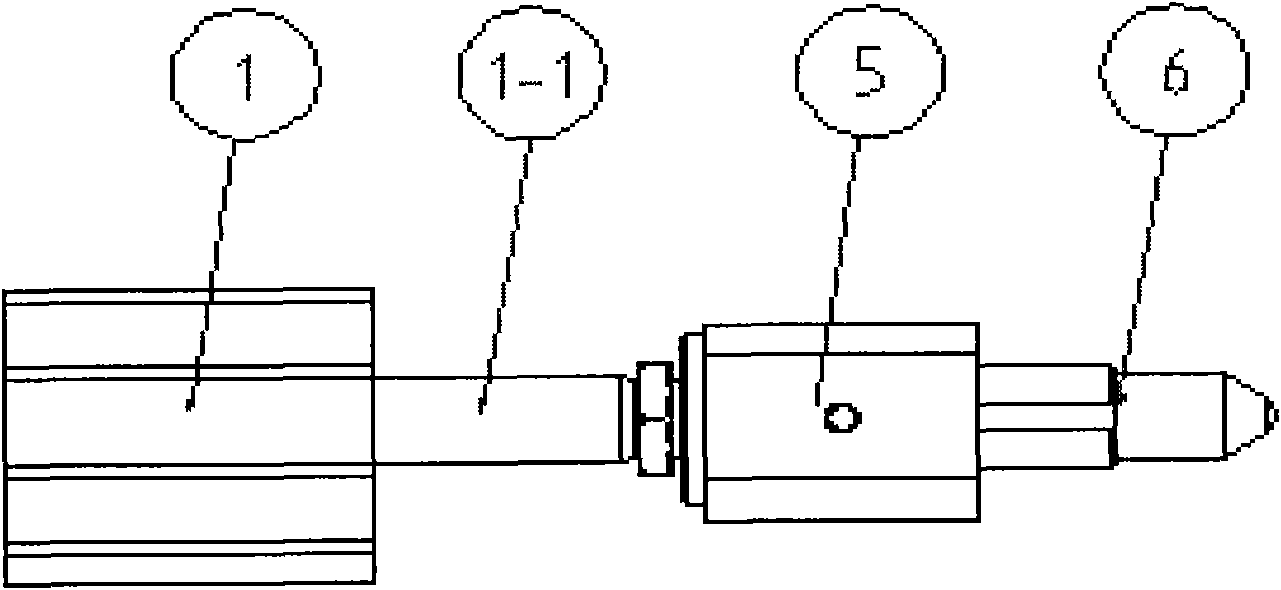

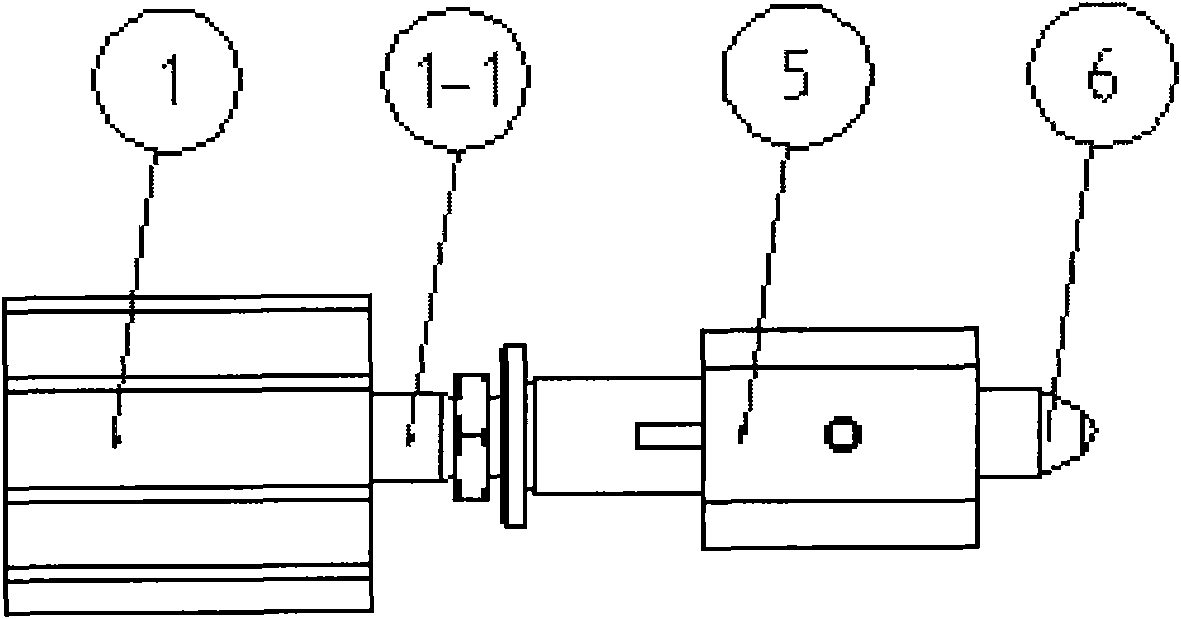

[0022] Embodiment: a kind of pneumatic propulsion device for the positioning pin of the welding fixture for automobile body (see figure 1 , Figure 2-a , Figure 2-b , image 3 ), including positioning pin 6, is characterized in that it is made up of driving part and positioning part; Said driving part is fixed on the fixture body, and its input end is the air source input, and output end connects the welding fixture positioning pin of automobile body 6; The said positioning part is fixedly installed on the driving part.

[0023] The positioning part mentioned above is composed of fixed parts and movable parts, wherein the fixed part includes: connecting plate 5, fixed corner seat 10, adjusting gasket 9 and travel switch mounting plate 3; the movable part includes: positioning pin 6, cylinder transmission rod 1-1; said fixed angle seat 10 is installed on the fixture body, and fixed angle seat 10 is connected with the driving part through the mounting plate 2; said mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com