Intelligent safety limit control system of hoisting equipment and working method thereof

A technology of lifting equipment and control systems, applied in the direction of safety devices, load hanging components, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

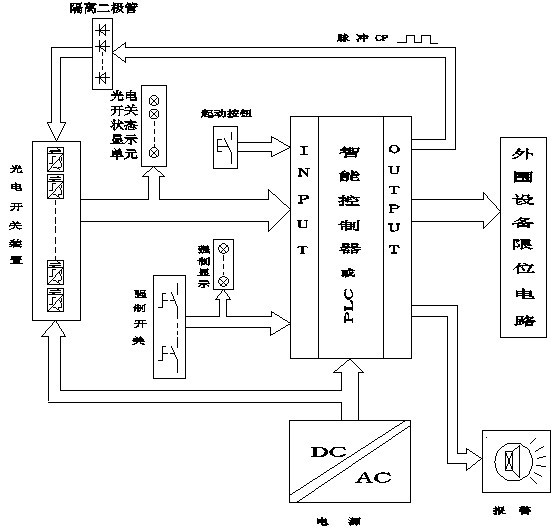

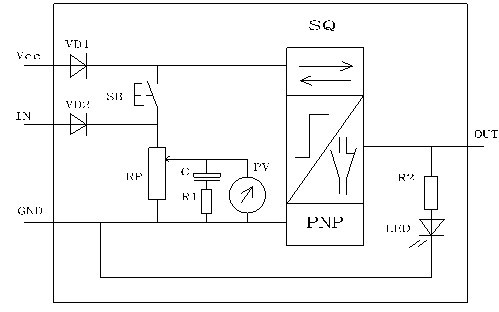

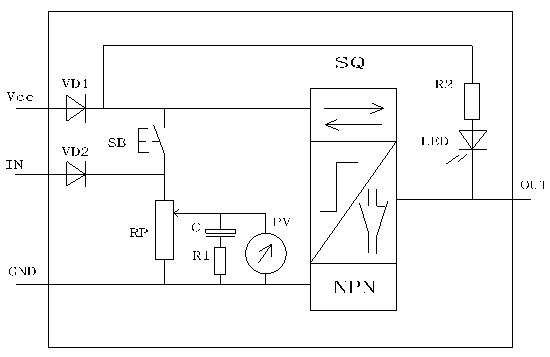

[0023] Such as Figure 4 Shown is the concrete circuit diagram of the present invention:

[0024] 1. Function allocation and description of input interface:

[0025] I1: Start button SB0-2, the power is turned on, and the system is initialized at the same time;

[0026] I2: Cart force button SB1, forcing the cart to output Q1 and Q2, and at the same time, the system alarm output Q7;

[0027] I3: trolley force button SB2, force the trolley to output Q3 and Q4, at the same time, the system alarm output Q7;

[0028] I4: SQ1, the limit device for the left travel of the cart, has the function of self-diagnosis, and at the same time, it can initialize the diagnosis of the system;

[0029] I5: SQ2, the limit device for the right travel of the cart, has the function of self-diagnosis, and at the same time, it can initialize the diagnosis of the system;

[0030] I6: trolley advanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com