Device and method for synthesizing zinc germanium phosphide polycrystal

A germanium phosphide and zinc synthesis device technology, applied in the direction of phosphide, can solve the problems of vacuum sealed tubes that cannot be recycled, low synthesis rate, low output rate, etc., to save experiment and production costs, high synthesis rate, The effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

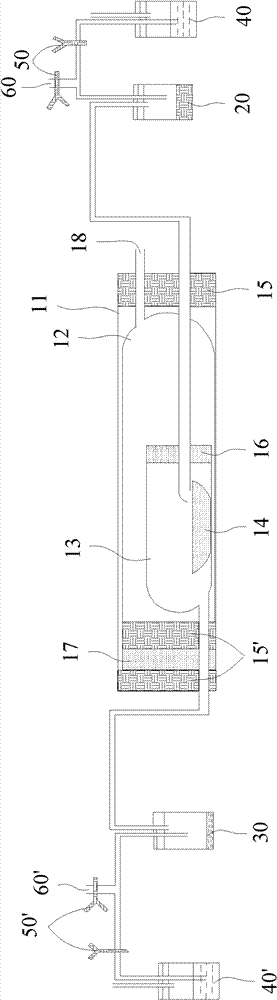

[0034] Put zinc and germanium in a stoichiometric 1:1 weight ratio of 50g in total, mix them uniformly and fully grind them under the protection of inert gas, and put them into the synthesis crucible 14, and put the synthesis crucible 14 containing the mixed raw materials of zinc and germanium into the internal reaction Room 13, press figure 1 After connecting the inner reaction chamber 13 and the argon protection chamber 12, place it in the furnace chamber (horizontal synthesis furnace) 11, vacuumize the inner reaction chamber 13 and the argon protection chamber 12, and then fill it with high-purity argon. Excess phosphorus is weighed and added into the evaporator 20 under an argon atmosphere. According to the stoichiometric amount of zinc and germanium used, the amount of phosphorus is 1.3-1.5 times of the stoichiometric amount of zinc or germanium. according to figure 1 After connecting the pipes, vacuumize the reaction tube as a whole, and repeatedly clean the entire gas ...

Embodiment 2

[0037] Put zinc and germanium in a stoichiometric ratio of 1:1.1 in a weight ratio of 150g, mix them evenly under the protection of an inert gas and grind them thoroughly, then put them into a synthetic crucible 14, and put the synthetic crucible 14 containing zinc-germanium mixed raw materials into the internal reaction Room 13, press figure 1 After connecting the inner reaction chamber 13 and the argon protection chamber 12, place it in the furnace cavity 11, vacuumize the inner reaction chamber 13 and the argon protection chamber 12, and then fill it with high-purity argon. Excess phosphorus is weighed and added into the evaporator 20 under an argon atmosphere. According to the stoichiometric amount of zinc and germanium used, the amount of phosphorus is 1.3-1.5 times of the stoichiometric amount of zinc or germanium. according to figure 1 After connecting the pipes, clean the entire gas path and reaction chamber repeatedly with high-purity argon for 3 to 5 times.

[0038...

Embodiment 3

[0040] Put zinc and germanium in a stoichiometric ratio of 1:1.05 in a weight ratio of 300g, mix them evenly under the protection of an inert gas and grind them fully, then put them into a synthetic crucible 14, and put the synthetic crucible 14 containing zinc-germanium mixed raw materials into the internal reaction Room 13, press figure 1 After connecting the inner reaction chamber 13 and the argon protection chamber 12, place it in the furnace cavity 11, vacuumize the inner reaction chamber 13 and the argon protection chamber 12, and then fill it with high-purity argon. Excess phosphorus is weighed and added into the evaporator 20 under an argon atmosphere. According to the stoichiometric amount of zinc and germanium used, the amount of phosphorus is 1.3-1.5 times of the stoichiometric amount of zinc or germanium. according to figure 1 After connecting the pipes, clean the entire gas path and reaction chamber repeatedly with high-purity argon for 3 to 5 times.

[0041] Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com