Air flow distribution plate at inlet of electrostatic dust collector

A technology of airflow distribution plate and electrostatic precipitator, which is applied in the manufacture of converters, etc., can solve problems such as unsatisfactory current equalization effect, achieve the effects of reducing the number of explosion vents, suppressing eddy currents, and enhancing the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

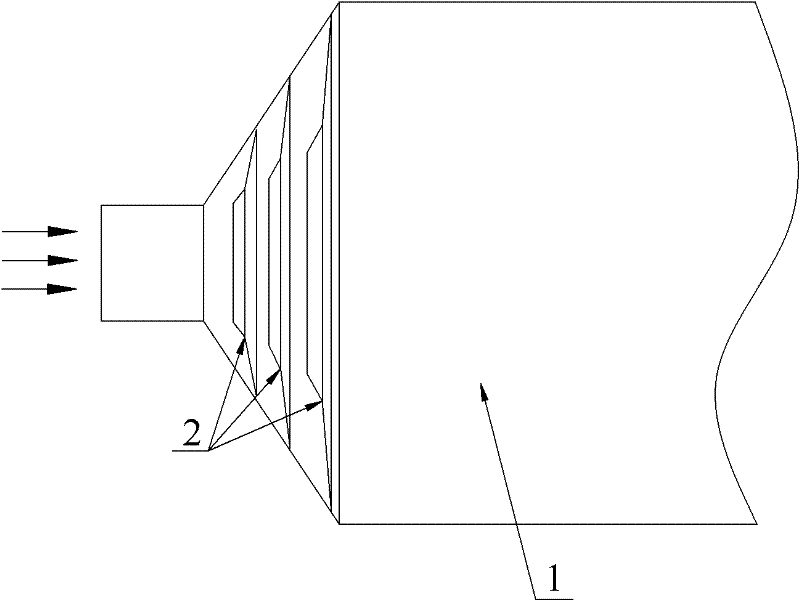

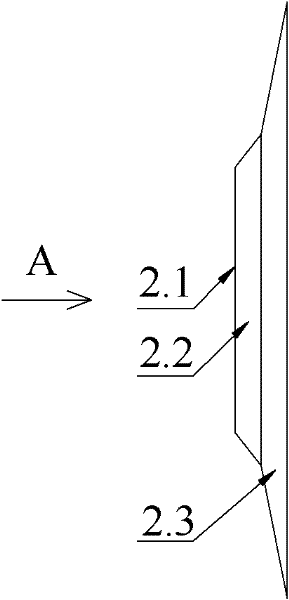

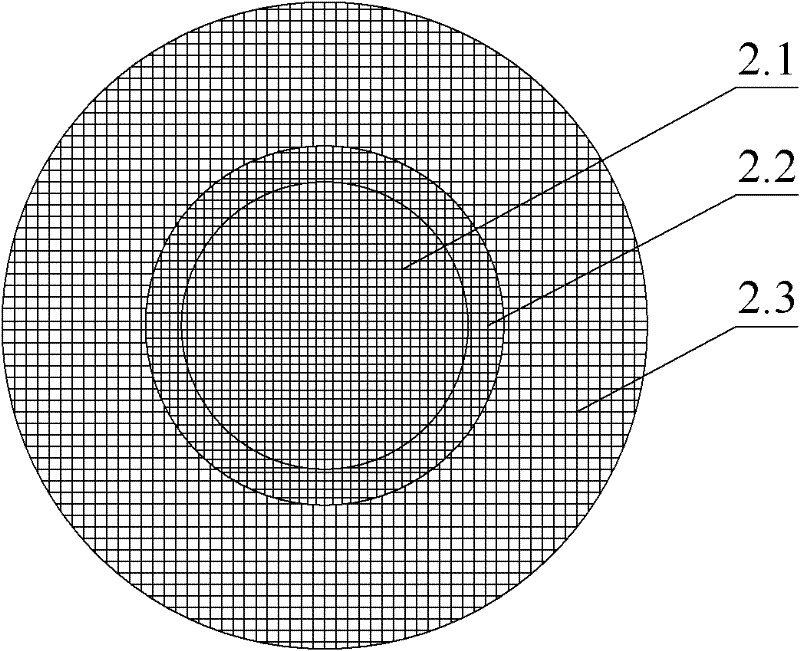

[0021] like Figure 1 to Figure 3 As shown, taking an electrostatic precipitator whose bell opening angle at the entrance is 110° as an example, the inlet airflow distribution plate 2 of a kind of electrostatic precipitator of the present invention is dish-shaped and is made of a carbon steel plate with a thickness of 6mm. There are square through holes. The airflow distribution plate 2 is sequentially spliced from the center to the outside by the distribution plate I area 2.1, the distribution plate II area 2.2 and the distribution plate III area 2.3. Among them: the area of area 2.1 of the distribution plate accounts for 21% of the area of the entire air distribution plate 2, it is perpendicular to the axis of the air distribution plate 2, and its opening rate is 50%; the area of area 2.2 of the distribution plate accounts for the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com