Gap diversion type axial-flow pump impeller

A technology for axial flow pumps and slits, which is applied in the field of slit drainage axial flow pump impellers, can solve problems affecting pump efficiency and energy loss, achieve the effect of eliminating wake vortex resistance and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

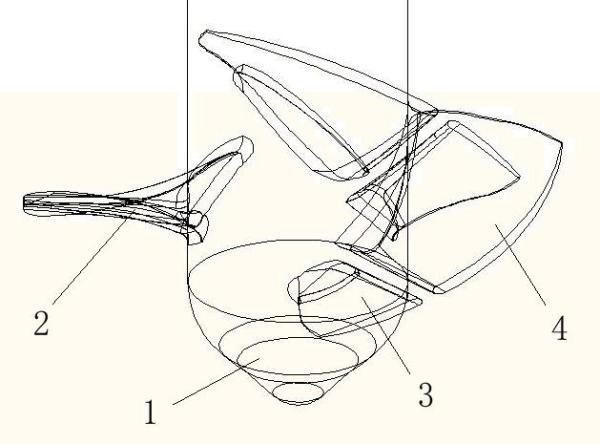

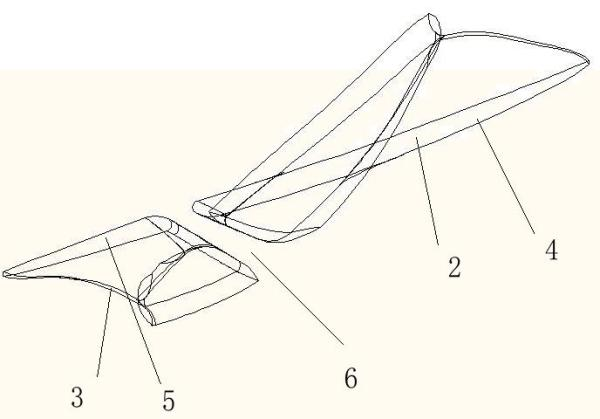

[0019] Embodiment one: see figure 2 and image 3 The impeller of the slit drainage type axial flow pump includes a hub 1 and a blade 2 fixed thereon, and a gap 6 is opened in the middle of the blade so as to divide the blade 2 into a front blade 3 and a rear blade 4 .

Embodiment 2

[0020] Embodiment Two: This embodiment is basically the same as Embodiment One, and the special features are as follows: with reference to the attached figure 2 And attached image 3 , the impeller of the axial flow water pump is composed of a hub 1 and blades 2 fixed on it, wherein the blades 2 are evenly distributed on the hub 1, and the number of blades 2 can be three, four or other numbers, mainly according to the design requirements of the pump to select the number of blades.

[0021] The impeller in this embodiment can be a cast impeller made of grease sand, resin sand or paste gold sand, or a precision cast impeller, or can be a metal processing impeller or a welded impeller. In addition, the idea of this embodiment is not only applied to the impeller of the axial flow water pump, but also applicable to centrifugal or mixed flow impeller blades. Regardless of the type of impeller blade, the opening direction of the gap 6 should conform to the flow direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com