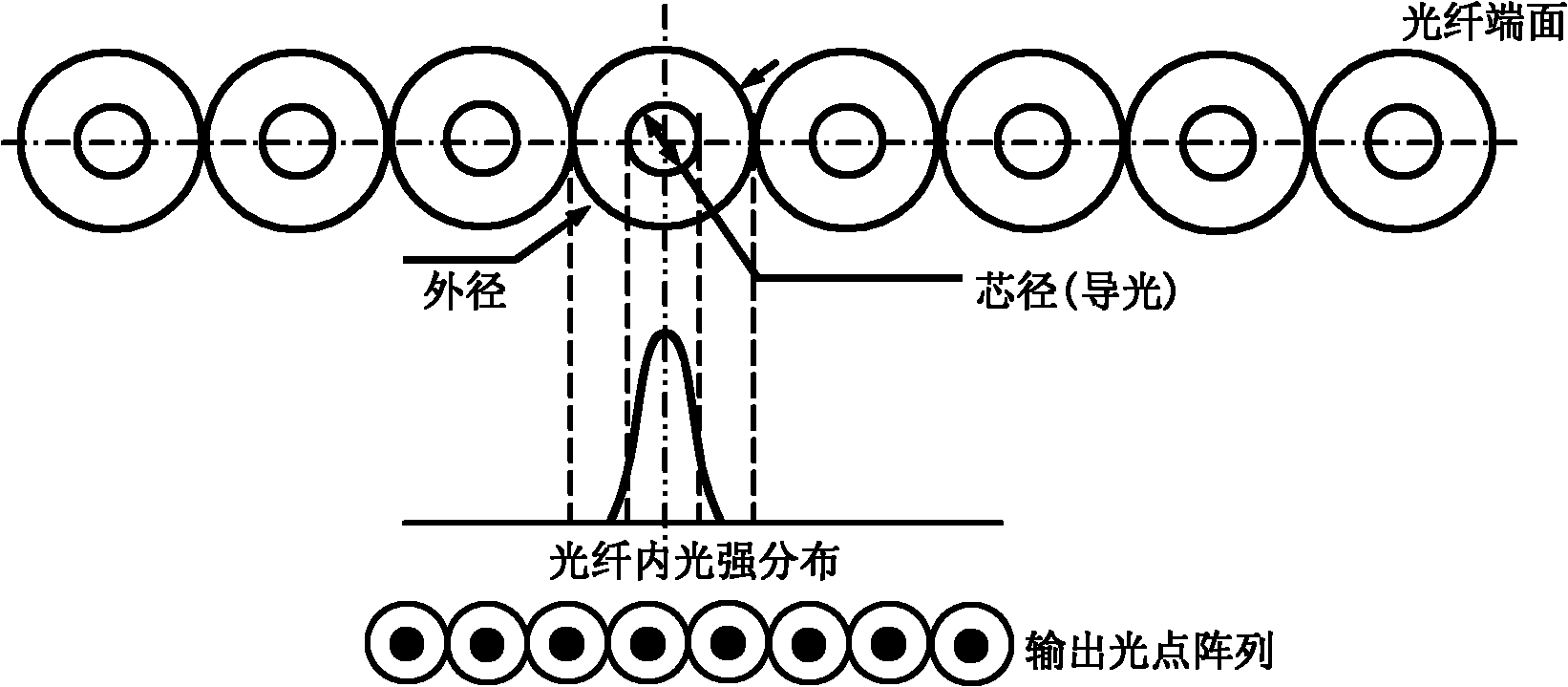

Method for implementing light spot joint seal in fiber densely-arranged line array and module

A technology of optical fiber module and line array, which is applied in the field of optical fiber close-packed scanning imaging, which can solve the problems of large width of close-packed array, complex control circuit, and high requirements for focusing imaging optical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

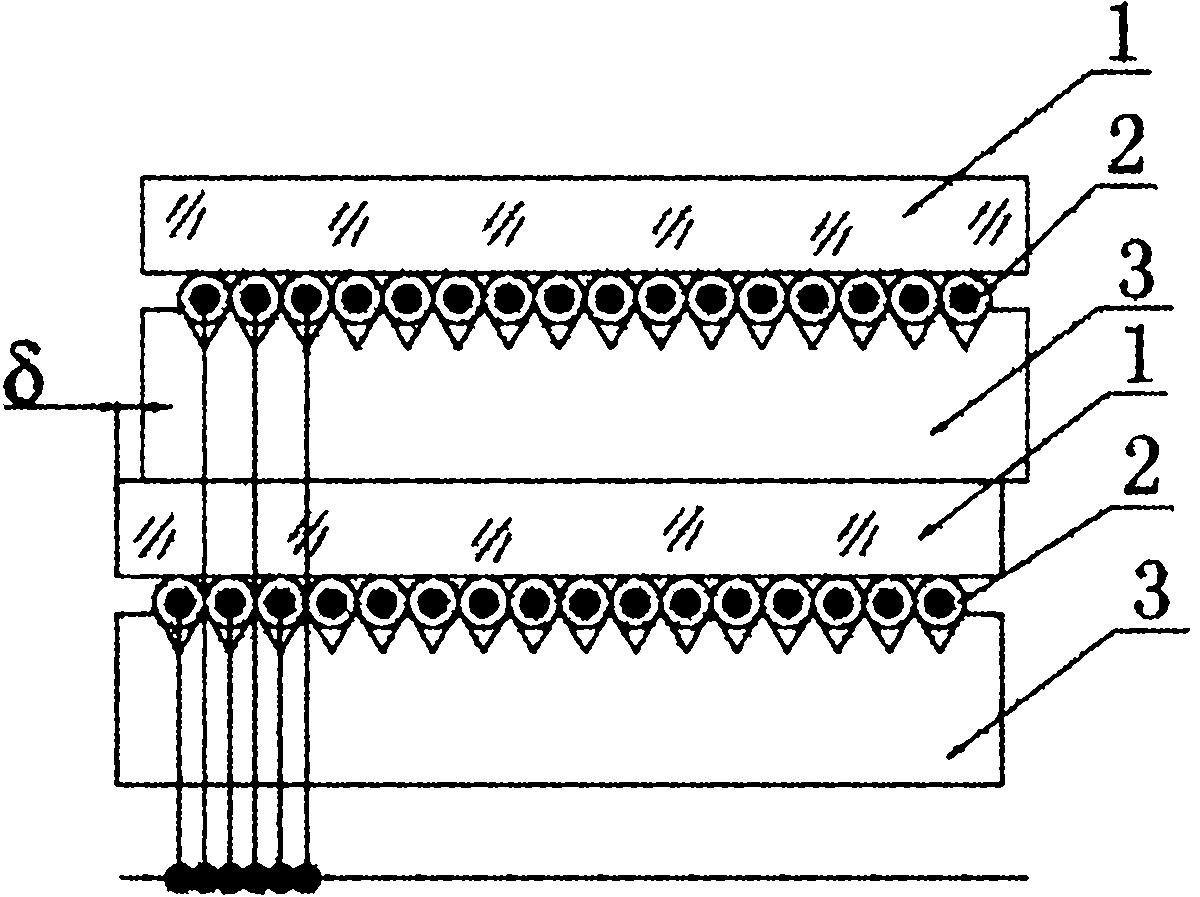

[0031] (Using a single-sided V-groove substrate to make a 128-way double-layer staggered optical fiber close-packed array)

[0032]Using standard 62.5 / 125 multimode optical fiber, arrange the optical fiber in the V-shaped groove of the substrate (silicon substrate or organic polymer substrate) with equally spaced V-shaped grooves on one side, drip UV glue, cover The upper glass plate is irradiated with ultraviolet light to cure it, and a module with 64 optical fibers is produced. Using the same process, the same 64-channel optical fiber close-packed module was fabricated. Stack the two 64-channel optical fiber close-packed modules up and down, and precisely control the position of the two modules in the direction of the fiber array, so that the corresponding optical fibers of the two modules are staggered by a distance of 62.5 microns, and then use ultraviolet glue to glue the two modules together. Solidified as a whole, thus a double-layer optical fiber close-packed array wi...

Embodiment 2

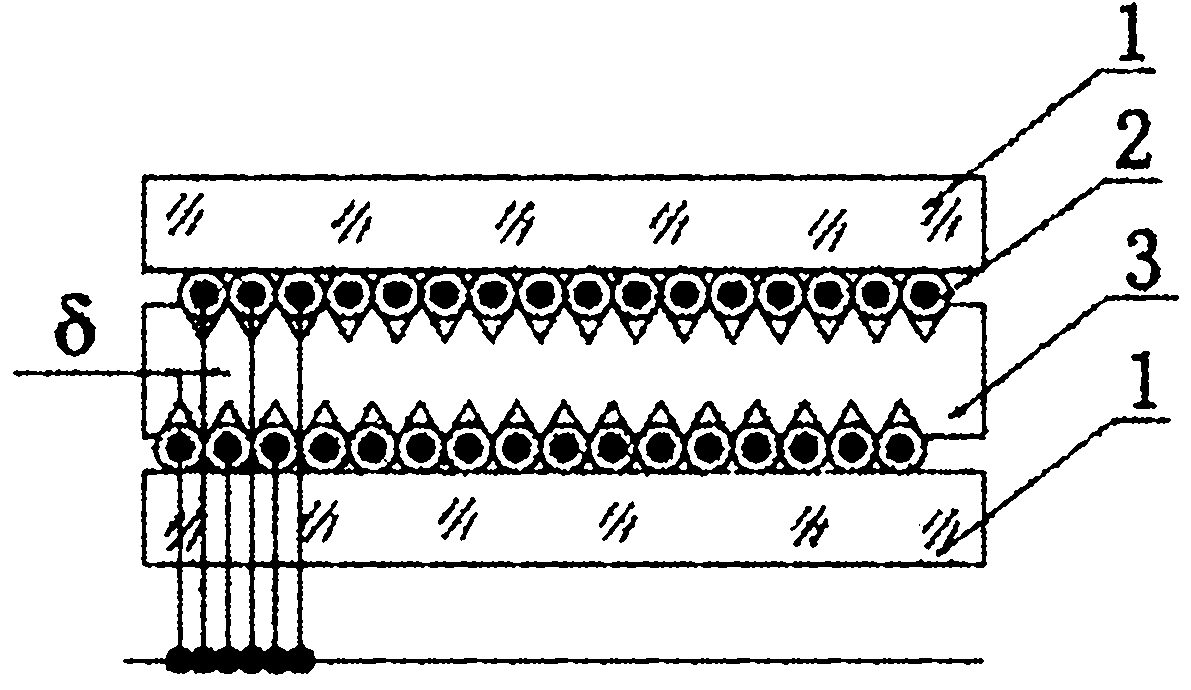

[0036] (Using double-sided V-groove substrates to fabricate 128-way double-layer staggered optical fiber close-packed arrays)

[0037] Make a substrate (silicon substrate or organic polymer substrate) with V-shaped grooves distributed at equal intervals on both sides, so that the V-shaped grooves on both sides are staggered left and right by 62.5 microns in the vertical direction, using the standard 62.5 / 125 more Mode optical fiber, operate on the two surfaces of the substrate respectively, first place the optical fiber on the V-groove position on one of the surfaces, drip UV glue, cover the glass platen, irradiate it with UV light to cure it, repeat the above process, complete the operation on the other side, that is, a module with 128 double-layer optical fibers densely packed can be produced, such as image 3 As shown, 1 is the glass plate, 2 is the standard 62.5 / 125 multimode fiber, 3 is the substrate, and δ is the distance between the two layers of optical fiber.

Embodiment 3

[0039] (Using a single-sided V-groove substrate to make a 256-way four-layer staggered optical fiber close-packed array)

[0040] Using 30 / 125 multimode optical fiber, arrange the optical fiber on the substrate (silicon substrate or organic polymer substrate) with V-shaped grooves distributed at equal intervals on one side, drip UV glue, cover the glass plate, and use It is cured by ultraviolet light irradiation, and a module with 64 optical fibers is produced. Using the same process, three identical optical fiber close-packed modules with 64 channels were fabricated. Stack the four 64-channel optical fiber close-packed modules up and down, and precisely control the positions of the four modules in the direction of the fiber array, so that the corresponding optical fibers of adjacent modules are sequentially staggered by a distance of 31.25 microns, and then glue the four modules together with ultraviolet glue. The module is solidified into a whole, so that a four-layer optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com