Linear light beam reshaper

A technology of beam shaping and shaper, which is applied in lasers, laser components, optics, etc., can solve the problems of increasing the difficulty of processing and side coating, the inability to adjust the distance of split beams, and increasing beam loss, etc., to achieve easy processing and easy installation , Improve the effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

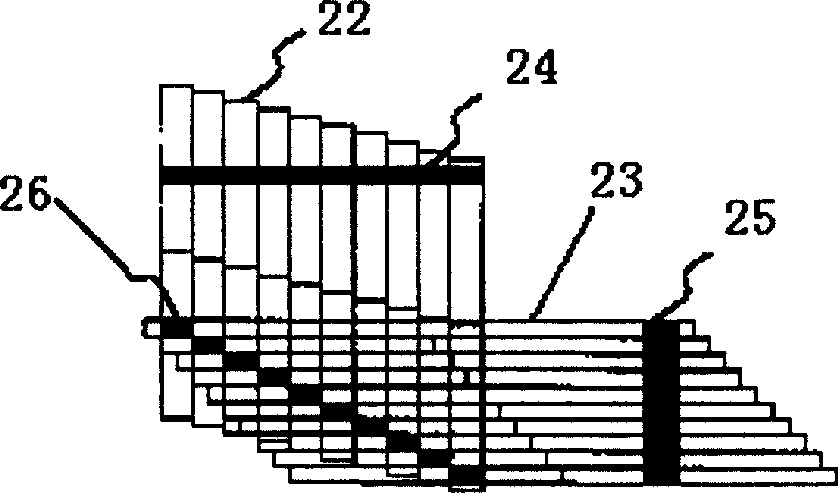

[0028] like Figure 10 The shaper shown by Figure 9 The prisms shown are misaligned and closely packed. Assume that the length of the linear beam after collimation on the fast axis is D=12mm, and the divergence angle of the slow axis is θ s =10°, fast axis divergence angle θ f =0.5°, take N = θ s θ f = 20 , Then the misalignment distance between the prisms is 12 20 = 0.6 mm , The outgoing beam must meet the same Lagrange quantity in the two directions to achieve the effect of shaping D / N×θ s =N×d×θ f , d=0.6mm can be obtained, then the optical path difference Δd=0 of the light beam between the first reflective surface and the second reflective surface of each prism, and the requirement of beam shaping can be achieved by making each pri...

Embodiment 2

[0030] Assuming that the light source to be shaped is a diode array composed of two diodes, the beams collimated by the fast axis are two parallel linear beams, the length of each linear beam is D=12mm, and the divergence angle of the slow axis is θ s =10°, fast axis divergence angle θ f =0.5°, suppose the linear light beam interval is 0.3mm, the same as example 1, the misalignment distance of the prism is 0.6mm,

[0031] The obtained Lagrange quantities of the reshaped beam in two directions are the same as those in Example 1, because the power of the two beams is doubled, and the brightness of the reshaped beam is also doubled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com