Helical packaging structure of light-emitting semiconductor chip and light-emitting semiconductor light source device thereof

A technology for light-emitting semiconductors and packaging structures, which is applied to semiconductor devices, lighting devices, components of lighting devices, etc., can solve the problems of semiconductor packaging structures that are difficult to obtain light-emitting arcs, impossible to attach light-emitting semiconductor chips, and reduce production efficiency. , to achieve the effect of improving performance and yield, reducing positioning accuracy requirements, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

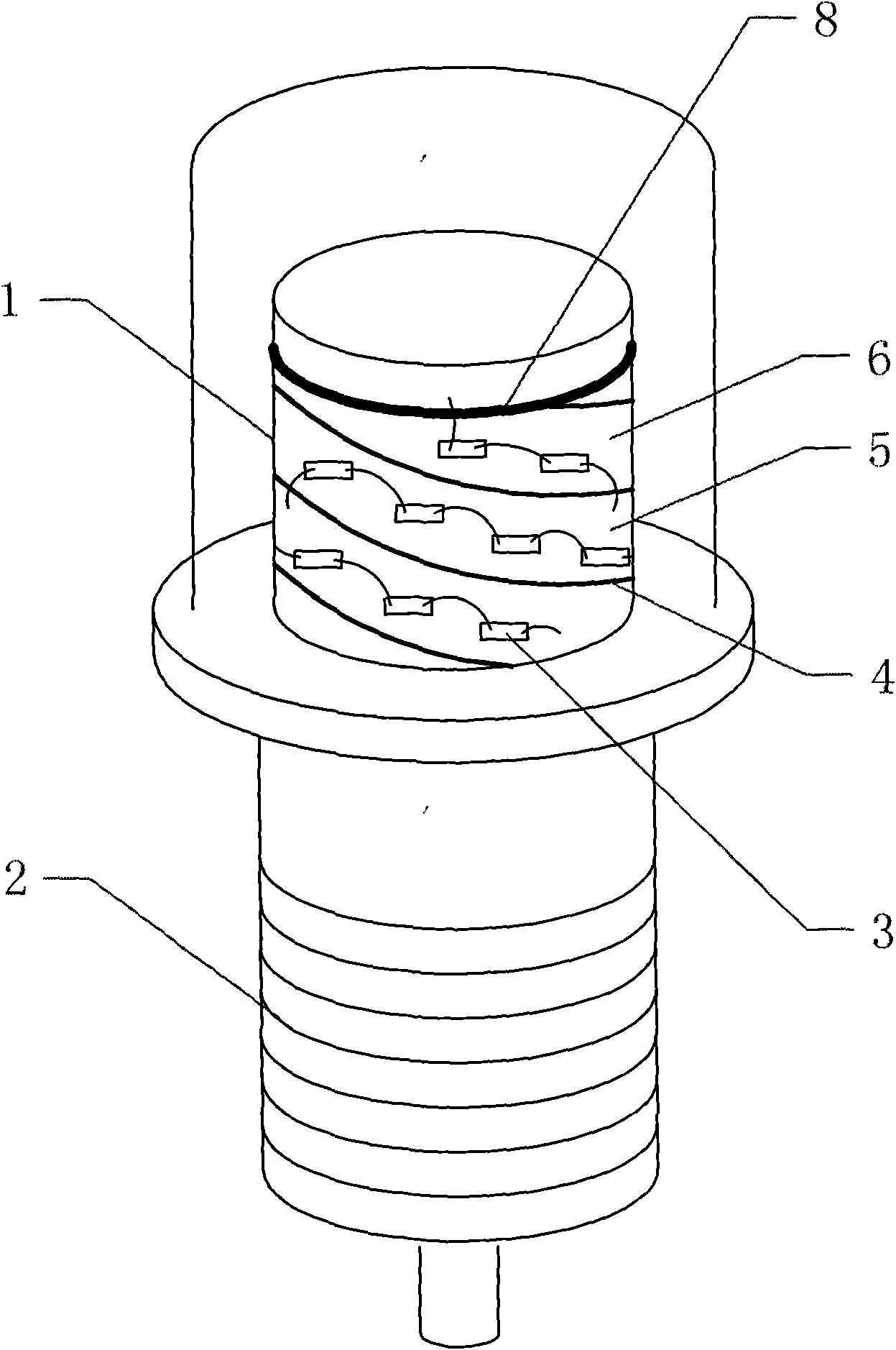

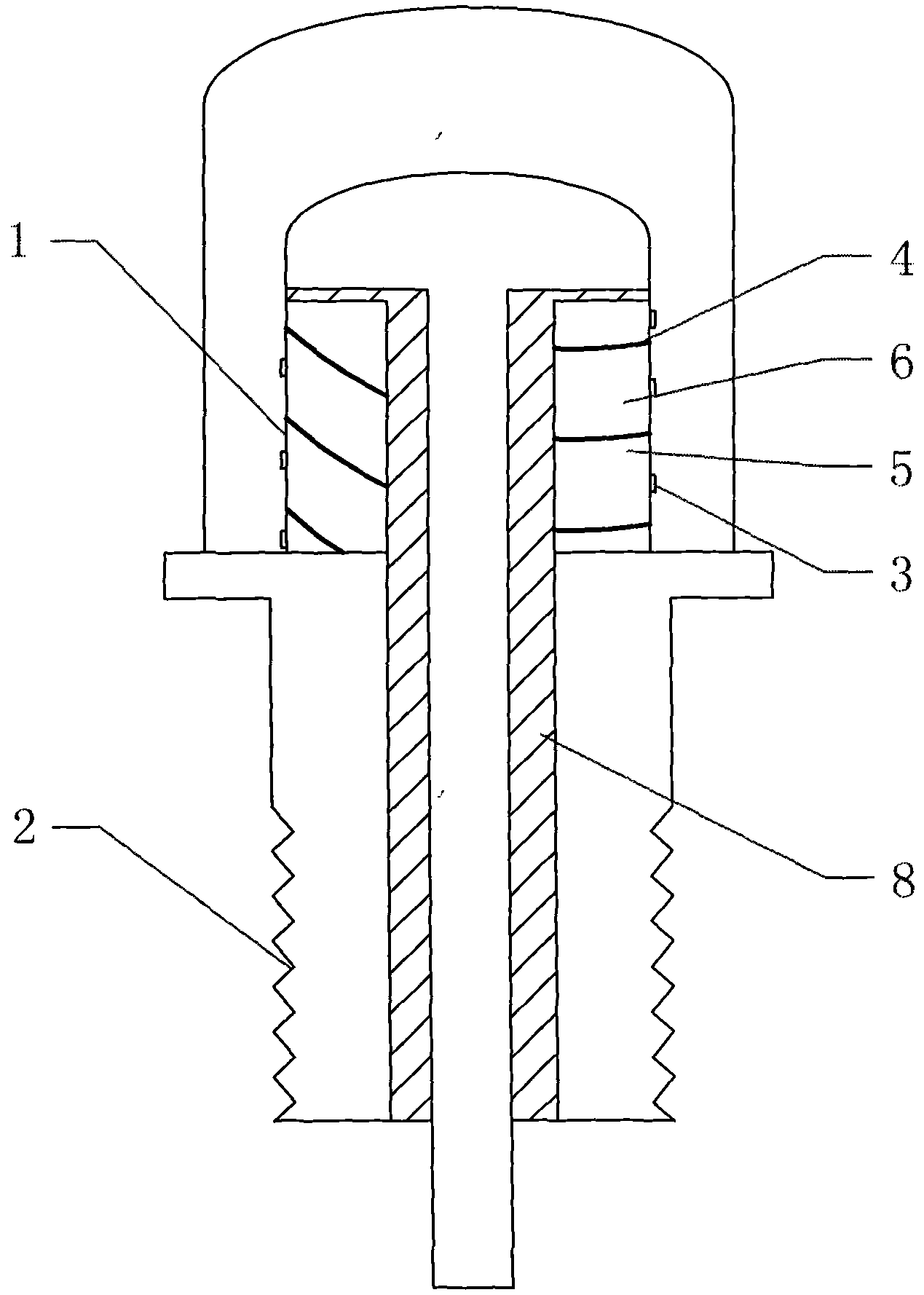

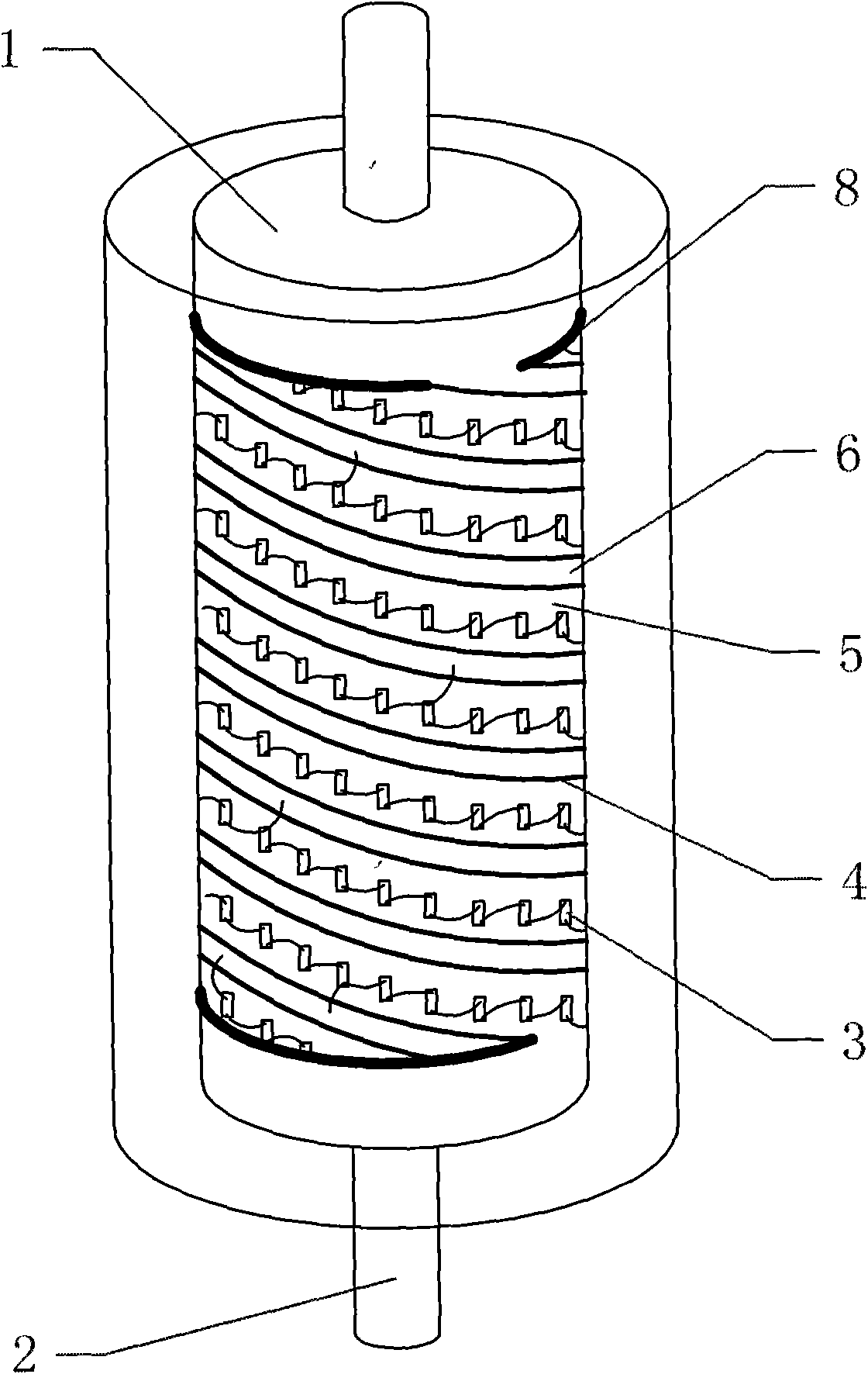

[0023] The present invention provides a spiral packaging structure for light-emitting semiconductor chips, which includes a columnar body 1 , two conductive electrodes 2 and a plurality of light-emitting semiconductor chips 3 . The columnar body 1 and the two conductive electrodes 2 are fixed into one body. In order to attach more light-emitting semiconductor chips 3 on the limited packaging surface, and to shorten the length of wires between the light-emitting semiconductor chips 3, especially the lead-out ends of the light-emitting semiconductor chips 3 after electrical connection, the side of the columnar body 1 The wall is also provided with two helical insulating strips 4, which surround the side wall of the columnar body 1 in parallel and separate the side wall of the columnar body 1 into two relatively independent helical packages. surface, that is, the anode packaging surface 5 and the cathode packaging surface 6, wherein the anode packaging surface 5 is electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com