Resin product manufacturing system, manufacturing method, resin molding apparatus, and mold

A product manufacturing and manufacturing system technology, applied in the field of resin molding devices and molds, to achieve stable resin volume and stable appearance and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]One embodiment of the present invention will be described below based on the drawings.

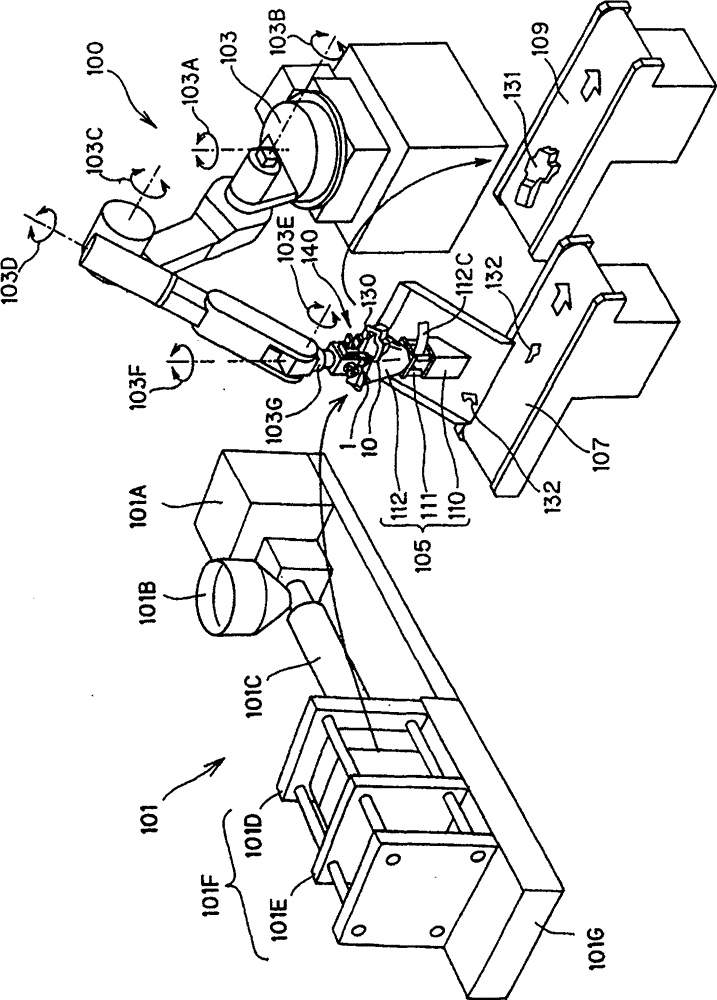

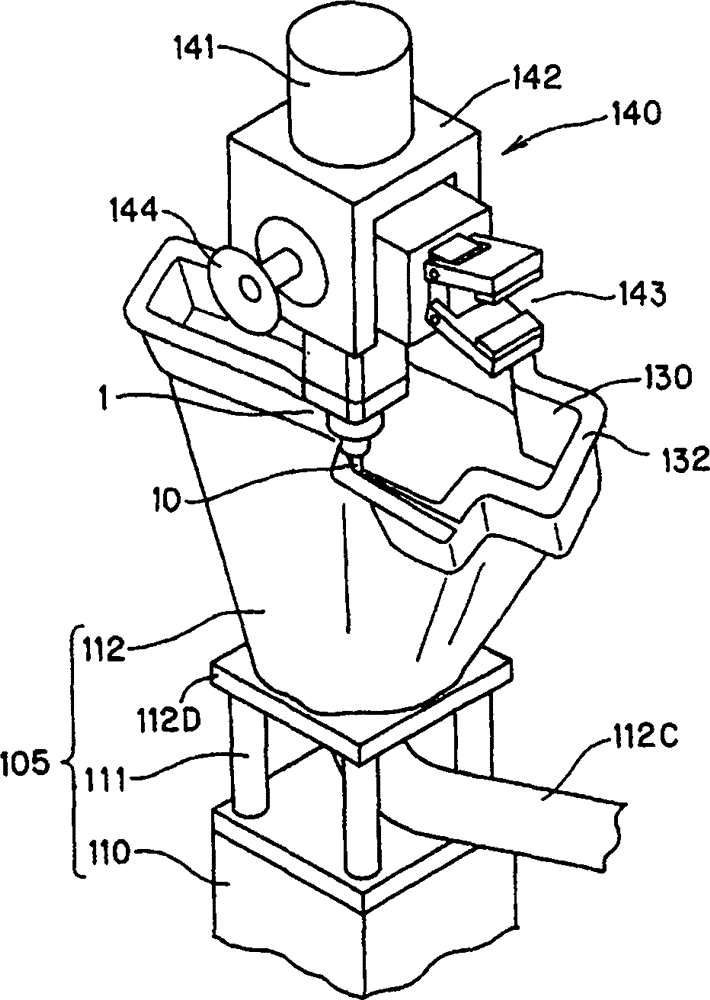

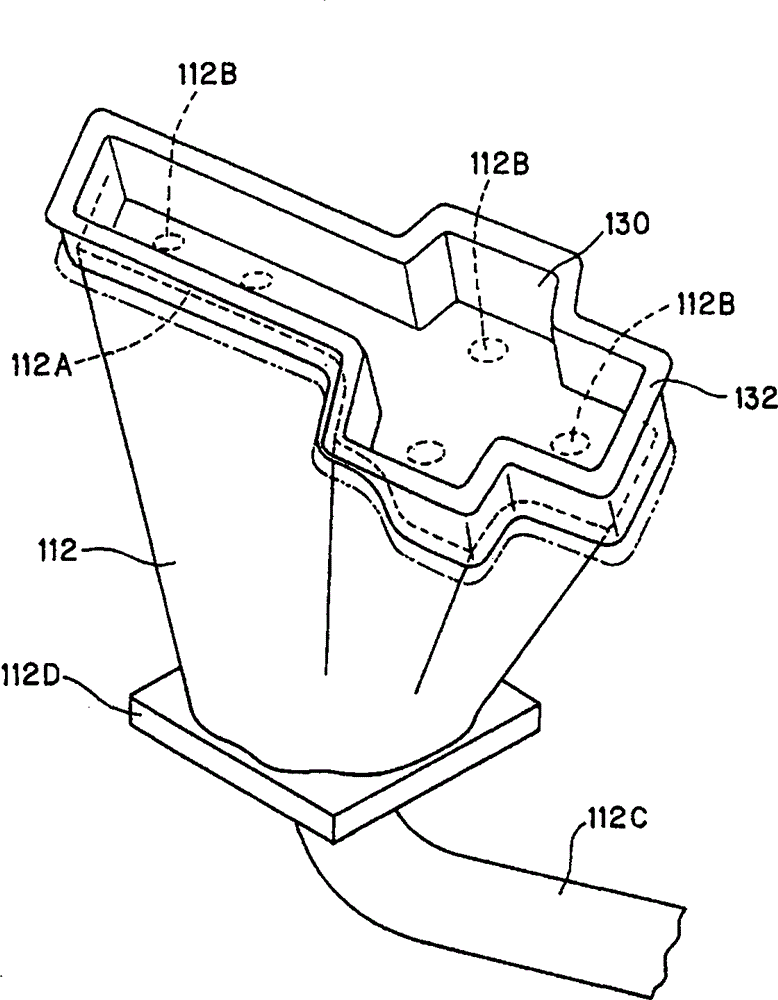

[0049] figure 1 Among them, 100 represents the resin product manufacturing system. This resin product manufacturing system 100 has a resin molding machine 101, a multi-joint manipulator 103 having a workpiece gripping device and a flash removal device at the front end of an arm, and a workpiece 130 which is an intermediate product before deburring (see Figure 4 ), the workpiece support mechanism 105 for removing the flash 132 to be discharged out of the system, the flash discharge conveyor 107, and the workpiece 131 as a finished product after deburring (see Figure 5 ) The finished product discharge conveyor 109 discharged to the outside of the system. In addition, although illustration is omitted, a storage stand for storing finished products may be installed instead of the finished product discharge conveyor 109 .

[0050] The resin molding machine 101 has a driving mechanism ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com