Titanium oxide coated carbon fiber and porous titanium oxide coated carbon material composition

A technology of titanium oxide and carbon materials, applied in the direction of carbon fibers, carbon compounds, fibrous fillers, etc., can solve the problems of increased leakage current and reduced power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

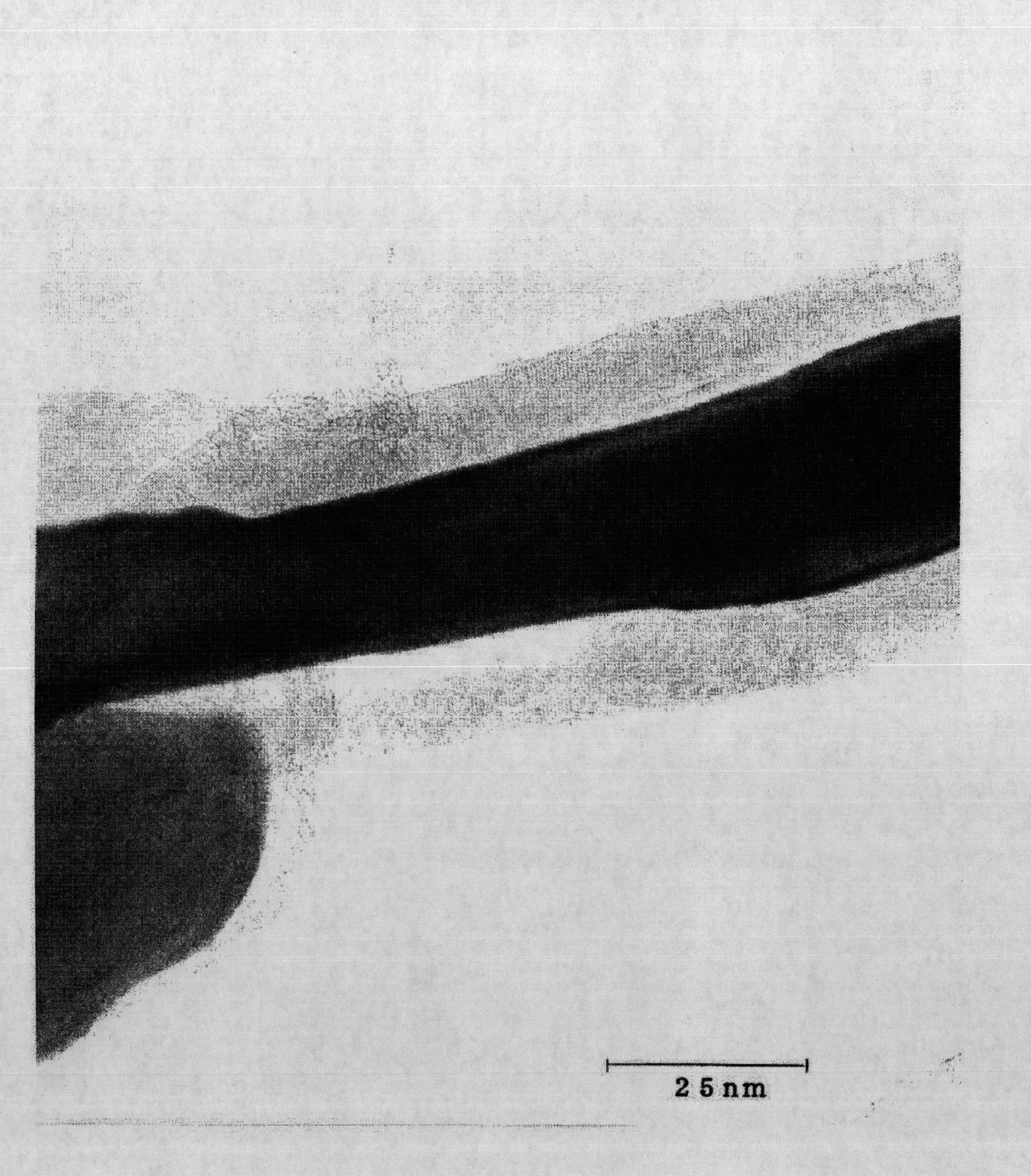

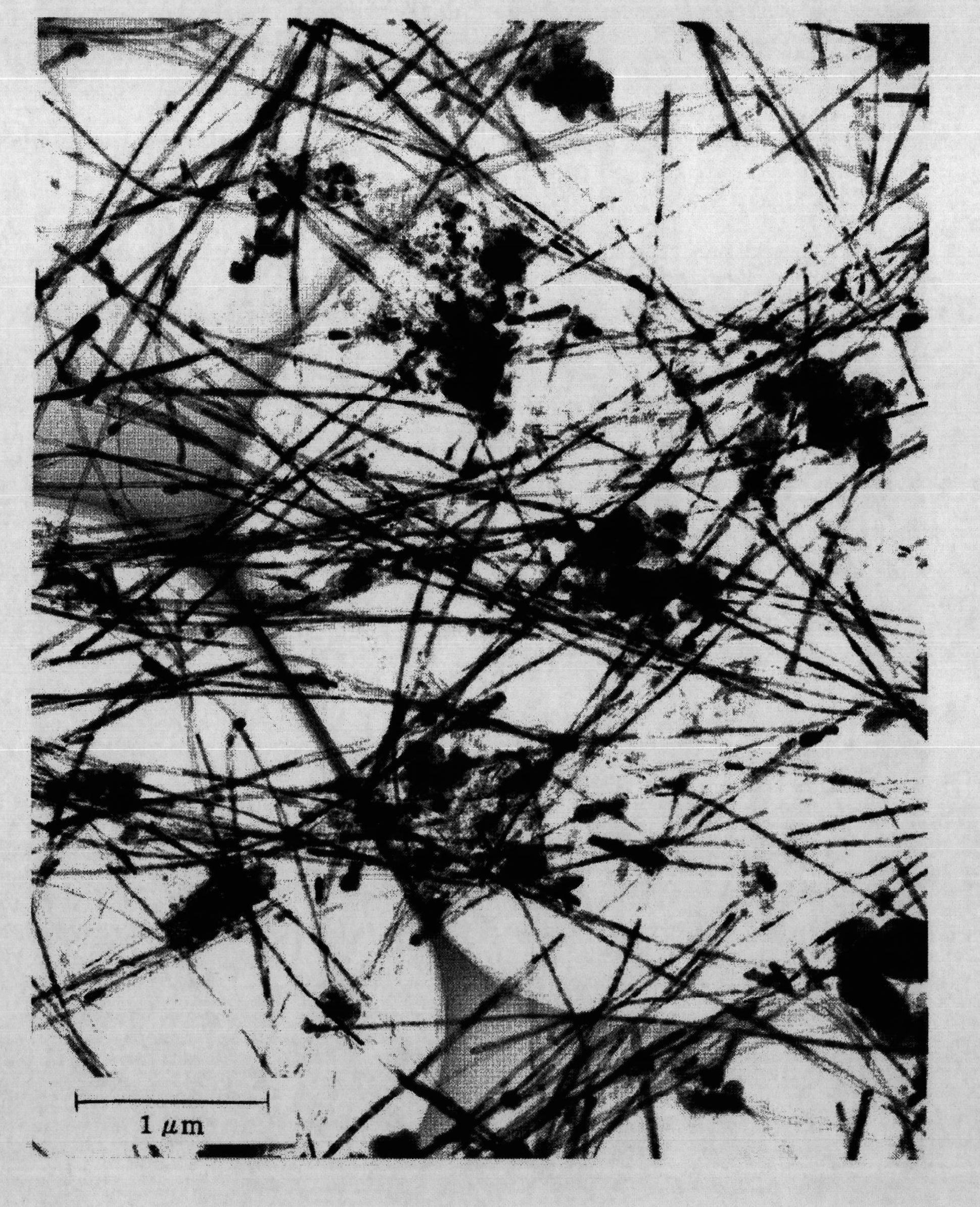

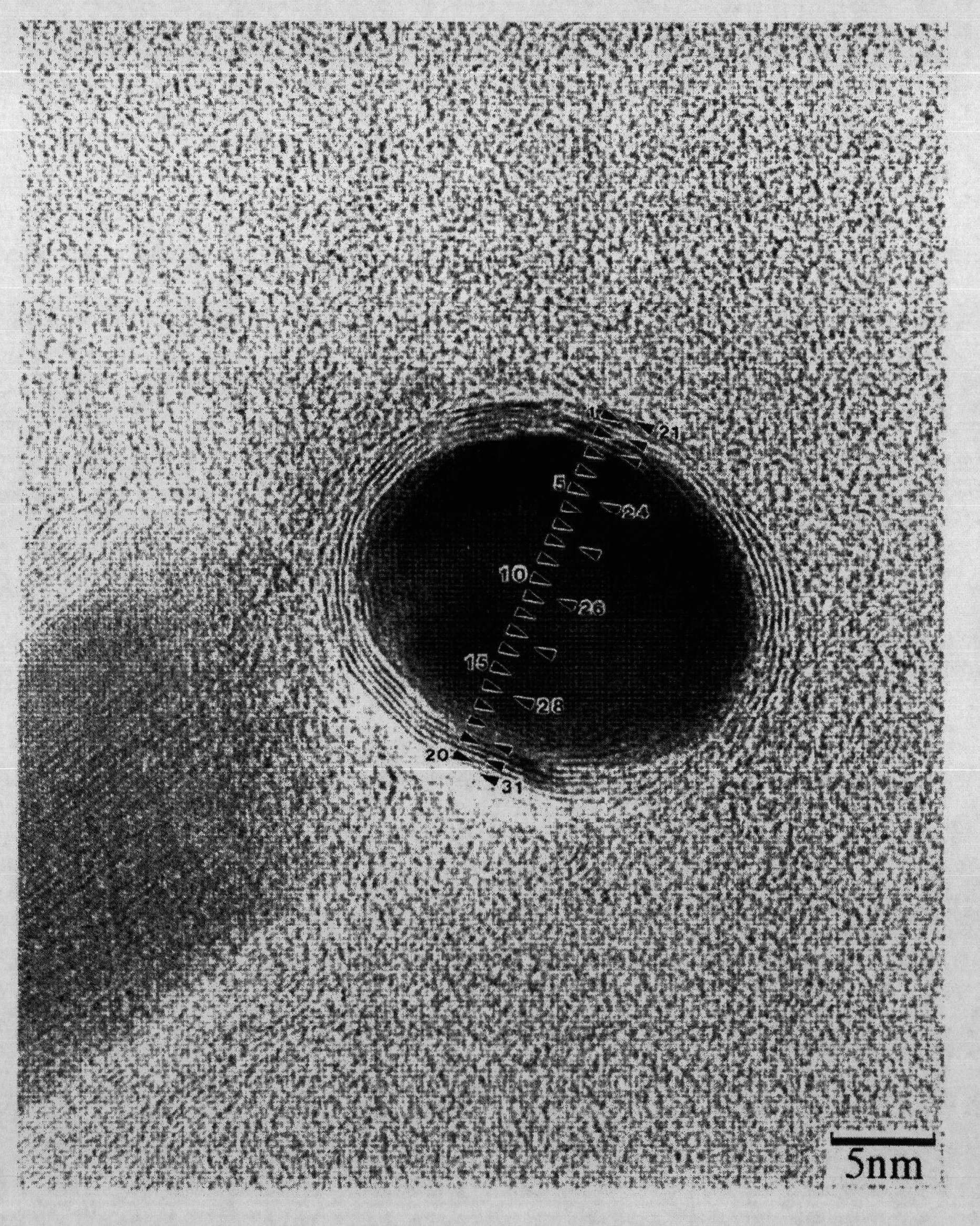

[0231] 150 g of 69% nitric acid was added to 0.96 g of carbon nanotubes (average diameter: 35 nm, average length: 5,000 nm, average aspect ratio: 143), and the mixture was maintained at 90˜95° C. for 6 hours. The resulting material was filtered, washed with distilled water until the filtrate showed a pH of 6-7, and dried.

[0232] The dried product was dispersed in 100 g of distilled water containing 3.7 g of polyether dispersant using an ultrasonic homogenizer. Ammonium hexafluorotitanate diluted to 1.0M and boric acid diluted to 1.0M were added to the nanoscale carbon dispersion at concentrations of 0.20M and 0.4M, respectively. The mixture was allowed to stand at 35° C. for 16 hours, followed by filtration and drying to obtain a structure in which the surface of the nanoscale carbon tubes was coated with titanium oxide (nanoscale carbon coated with titanium oxide Tube).

[0233] According to TG / DTA measurement, carbon nanotubes burn violently around 550°C, while the prepa...

experiment example 1-1

[0240] The structure before firing produced in Example 1 was processed into a 0.3 mm thick flat plate under a pressure of 10 MPa, and a voltage of 1 V was applied between the sheets. As a result, it was confirmed that the current value was 73 mA, and the powder resistance was 3.12 Ω·m, thereby confirming that the structure of Example 1 showed higher electrical conductivity than the structure of Comparative Example 1 using titanium oxide particles, and the electrical conductivity Rates were evaluated by the same method.

experiment example 1-2

[0242] The structure produced in Example 1 was heat-treated at 350° C., and then processed into a flat plate with a thickness of 0.3 mm under a pressure of 10 MPa; and a voltage of 1 V was applied between the press sheets. As a result, it was confirmed that the current value was 608 mA, and the powder resistance was 0.43 Ω·m, thereby confirming that the structure of Example 1 showed higher electrical conductivity than the structure of Comparative Example 1 using titanium oxide particles, and the electrical conductivity Rates were evaluated by the same method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com