Pre-filled glass syringe

A syringe and pre-filling technology, applied in the directions of syringes, infusion sets, etc., can solve the problems of increased cost and high cost, and achieve the effects of convenient processing, low production cost and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

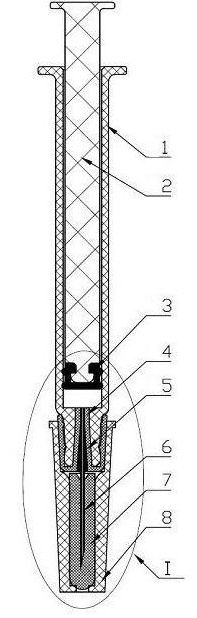

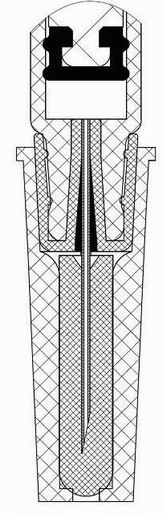

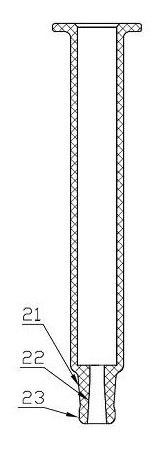

[0017] From figure 1 , figure 2 As can be seen in the figure, a pre-filled glass syringe includes a glass jacket 1, a core rod 2, a piston 3, a needle 6, a protective cap, and the like. The rear end of the glass jacket 1 is open, which can be filled with liquid medicine in advance, and the glass jacket is conducive to long-term storage of liquid medicine. The piston 3 is loaded into the glass jacket 1 after filling the medicine liquid, and it is also used as the sealing cover of the Chinese medicine solution in the glass jacket 1, which can slide and seal in the glass jacket 1. The piston 3 is connected with the core rod 2 and can be closed by the core rod 2 is driven to move in the glass jacket 1, and the needle 6 is installed and connected to the front end of the glass jacket 1, on which a protective cap is installed. The above specific composition and structure belong to the prior art and will not be described in detail.

[0018] The characteristics of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com