Automatic retraction type safety injector

A safety syringe and automatic retraction technology, applied in the field of medical devices, can solve the problems of complex structural design, waste, and inability to replace, and achieve the effects of improving work efficiency, convenient assembly and use, and good safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

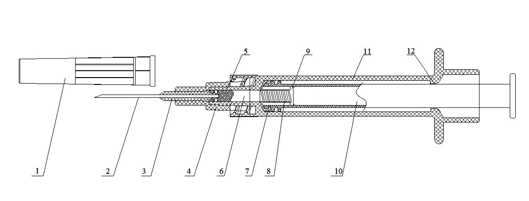

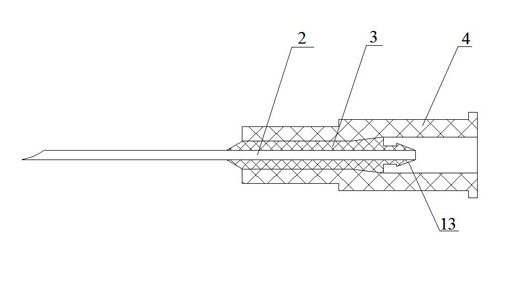

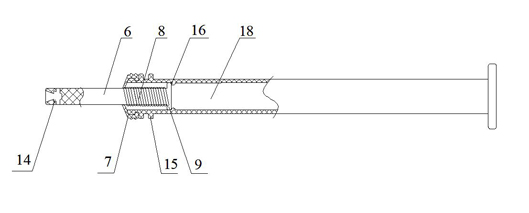

[0014] Example 1. refer to figure 1 , figure 2 , image 3 and Figure 4 . A self-retracting safety syringe, comprising an outer casing 11 and a core rod 10 arranged in the outer casing 11, the front of the outer casing 11 is connected with a needle assembly, and the needle assembly is provided with a sheath 1; the needle assembly includes a needle tube 2, a needle tube seat 3 and the needle tube outer seat 4, the needle tube seat 3 is arranged on the needle tube 2, the rear end of the needle tube seat 3 is provided with an engaging cone 13, the needle tube outer seat 4 is set on the needle tube seat 3, and the needle tube outer seat 4 rear end is provided with Threaded joint; the front end of the outer cover 11 is provided with an outer conical locking joint 17 connected with the threaded joint, and the outer cover 11 is also connected with at least two elastic damping claws 5 protruding forward from the outer cover 11. The core rod 10 It is a hollow core rod provided wi...

Embodiment 2

[0016] Example 2. In the self-retracting safety syringe described in Embodiment 1: a locking convex ring 12 is provided on the inner cavity wall at the rear end of the outer casing 11, and a locking convex ring 12 is provided on the outer wall of the core rod 10 on the rear side of the rubber plug 7 to cooperate with the locking convex ring 12. The locking boss 15 used. This can prevent the core rod 10 from being easily pulled out of the jacket 11 when it is pulled back. There can be two locking bosses 15, so that when the core rod 10 is not straightly pulled outwards, the locking boss 15 is not afraid of being pulled out beyond the locking convex ring 12.

Embodiment 3

[0017] Example 3. In the self-retracting safety syringe described in Embodiment 1: the front part of the plug 6 is provided with several liquid holes communicating with the engaging cavity 14 . In this way, when the injection is almost finished, the remaining medicinal liquid can go out from the needle tube 2 through the liquid hole, so that there is no medicinal liquid residue in the syringe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com