Electric spark machining method for inverted cone micropores

A processing method and micro-hole processing technology, which is applied in the field of electric discharge machining of inverted cone micro-holes, can solve the problems that cannot be adapted to the micro-hole processing of fuel injectors, and achieve the effect of rapid industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

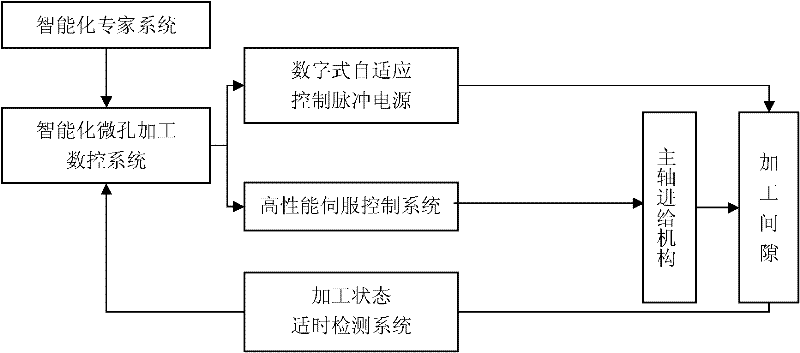

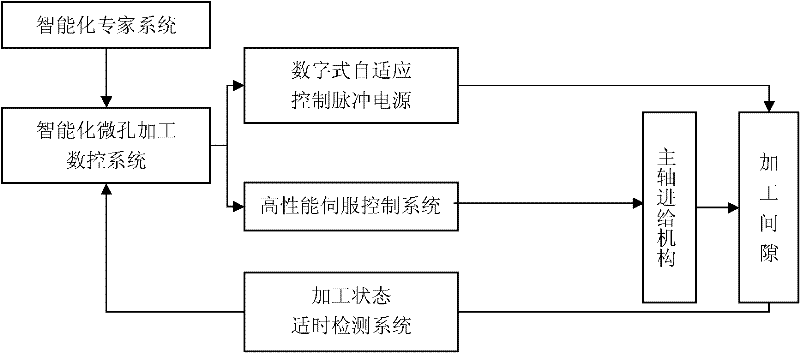

Image

Examples

Embodiment 1

[0017] Embodiment 1: An EDM machining method for inverted taper micro-holes is realized by using an EDM micro-hole machining device to detect the machining depth of the hole in real time, and control the pulse power supply parameters and servo feed speed of the EDM device to make the pulse power supply The discharge energy increases gradually with the increase of machining depth; the servo feed speed decreases gradually with the increase of machining depth. When machining micro-holes, first process with a fixed discharge energy to about half the depth of the hole to be processed, then gradually increase the discharge energy of the pulse power supply, and gradually adapt to reduce the servo feed speed until the discharge energy of the pulse power supply at the exit The initial 120%, and the servo feed speed is 80% of the initial, which gradually increases the probability of secondary discharge at the exit of the micro-hole, thus realizing the machining of the inverted-taper micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com