Device for manufacturing nano laminated composite material

A composite material and nano-laminated technology, which is applied in the field of advanced material processing, can solve the problems of flow channel design difficulties, layered structure damage due to flow boundary dragging, and the number of series connections should not be too large, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

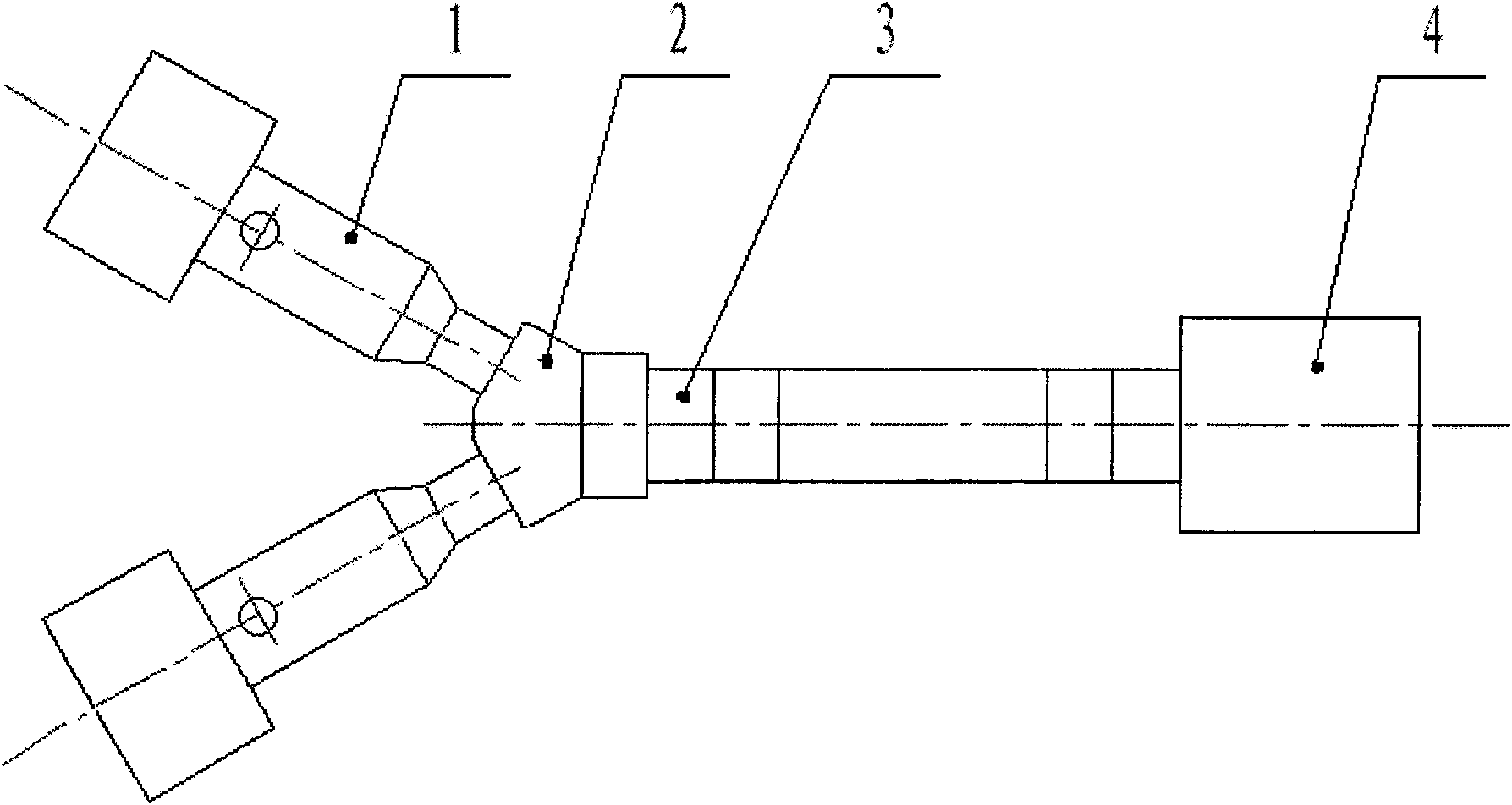

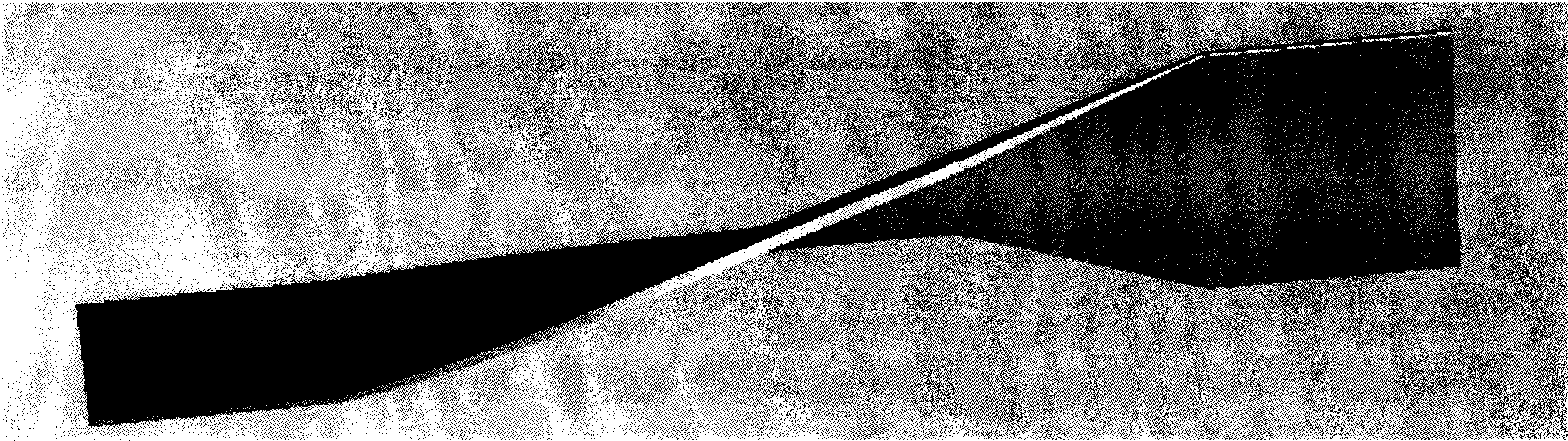

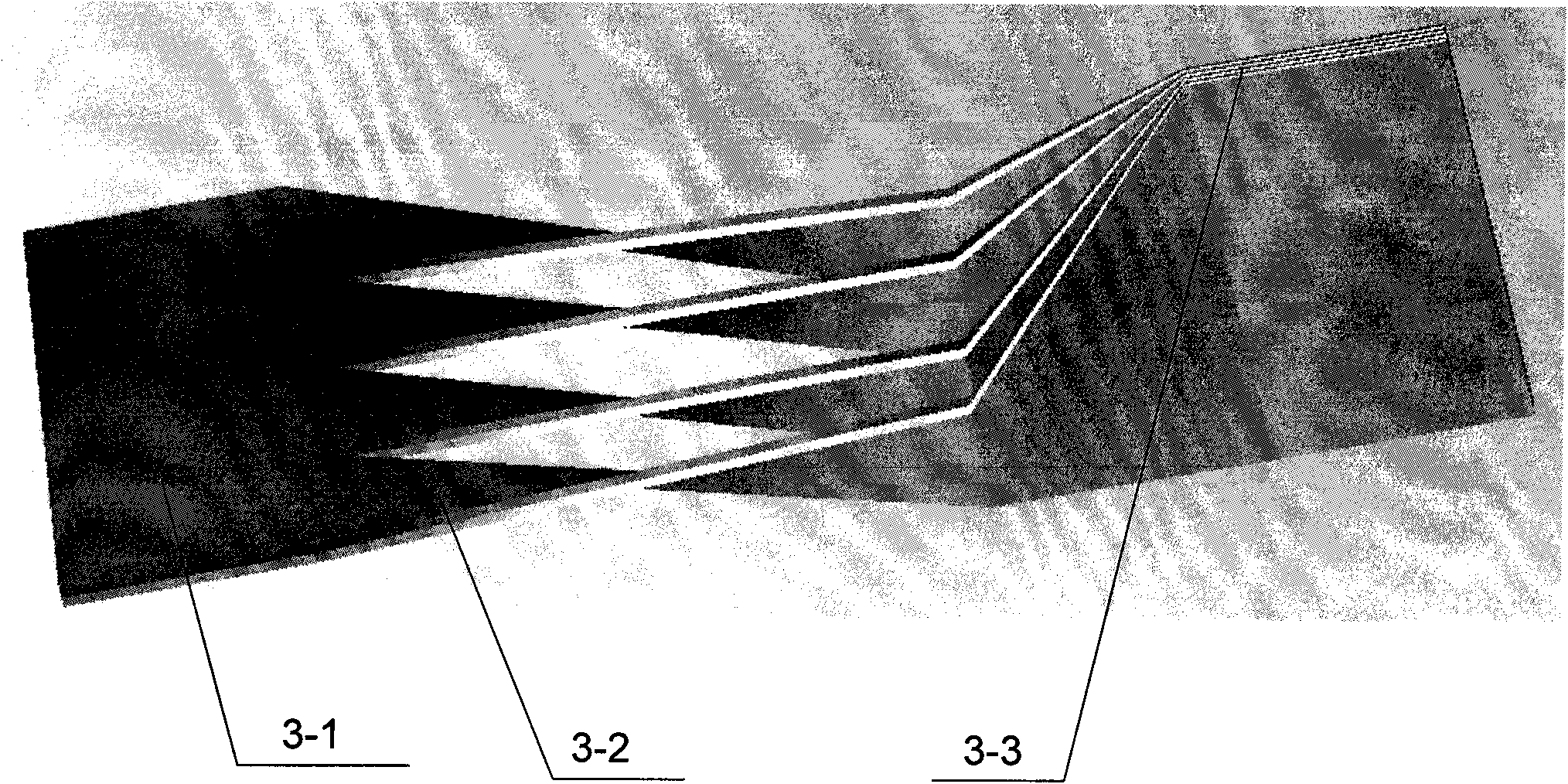

[0014] A device for preparing nano-laminated composite materials disclosed in this embodiment, the overall shape is as shown in the attached figure 1 As shown, it includes a plasticizing feeding device 1 with two or more extruders, a confluence 2, a laminated composite generator 3, and a molding device 4, which are connected in series in sequence. The main functional structure of the laminated compound generator 3 is to collect the polymer melts from n plasticizing feeding devices through the confluence 2 into n-layer polymer melts 3-1 in the confluence, and each layer melts The thickness of the body is the same, and the n-layer polymer melt 3-1 in the manifold is divided into m equal parts along the width direction when it leaves the manifold 2, and each equal part is divided into the stacked flow channel 3-1 of the laminated composite generator. 2, when they continue to flow forward, they rotate 90 degrees and widen m times, and merge into each other at the outlet end to for...

Embodiment 2

[0018] Another example of a nano-lamination composite material preparation device disclosed in this embodiment, the overall shape is as follows Figure 4 As shown, it includes a plasticizing feeding device 1, a confluence 2, a laminated composite generator 3, an injection nozzle 5 and a mold 6 with two or more injection molding machines. The injection nozzle 5 and the mold 6 form a molding device, and the plasticizing The feeding device 1, the confluence 2, the laminated composite generator 3, and the injection nozzle 5 are serially connected in sequence, and the nozzle 5 is connected with the mold 6 during injection molding. The main functional structure of the laminated composite generator 3 is to divide the n-layer polymer melt 3-1 extruded by the confluence into m equal parts along the width direction, and each equal part is divided into m equal parts in the laminated composite generator. When the stacked flow channel 3-2 continues to flow forward, it rotates 90 degrees an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com