Adjustable lifting cloth storage rack

A cloth storage rack and adjustable technology, applied in the field of cloth storage racks, can solve the problems of inability to adapt to various specifications of films, affecting the normal operation of printing production, film buckling and deformation, etc., achieving low work efficiency, uniform force, and reduced difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

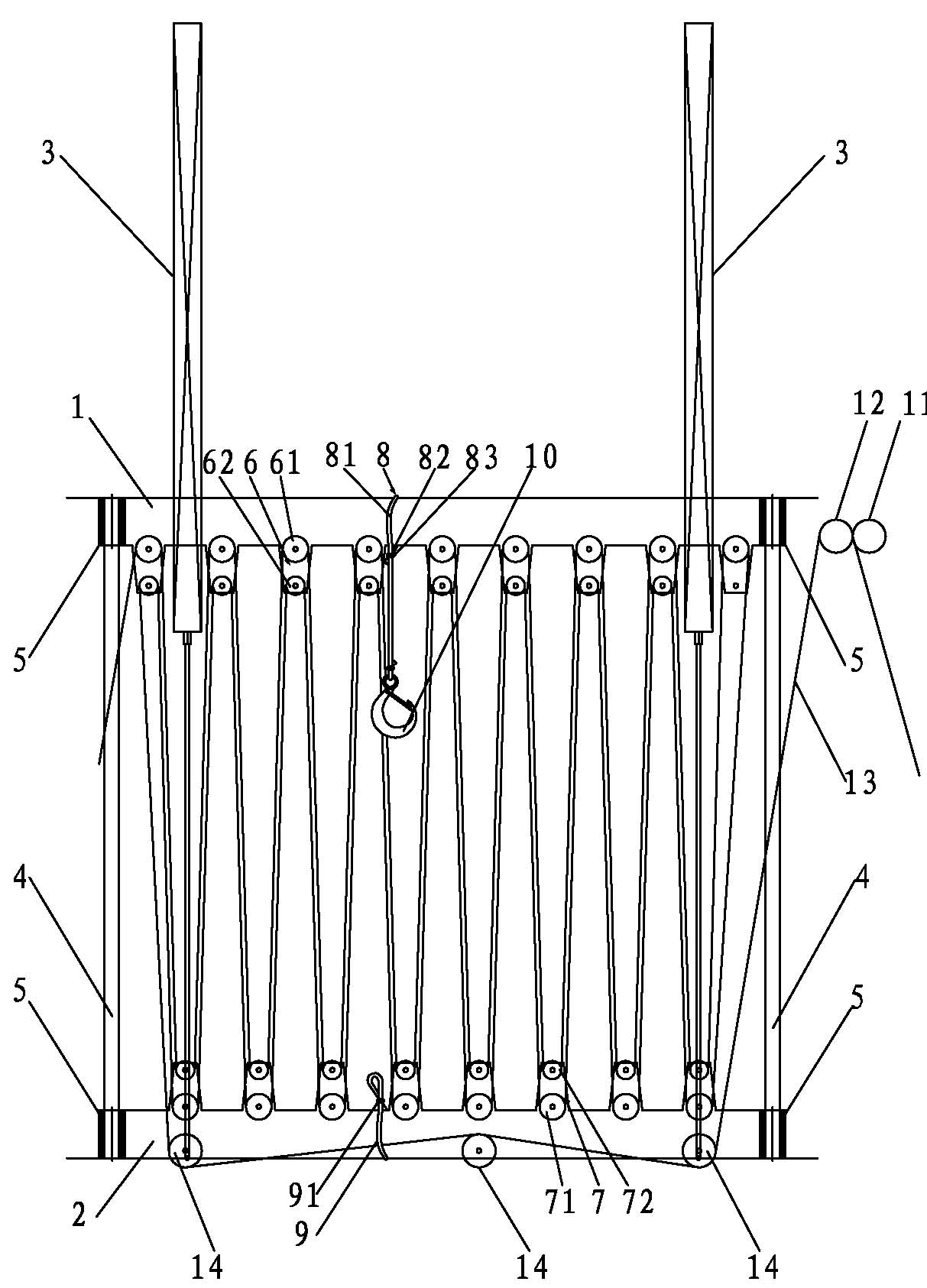

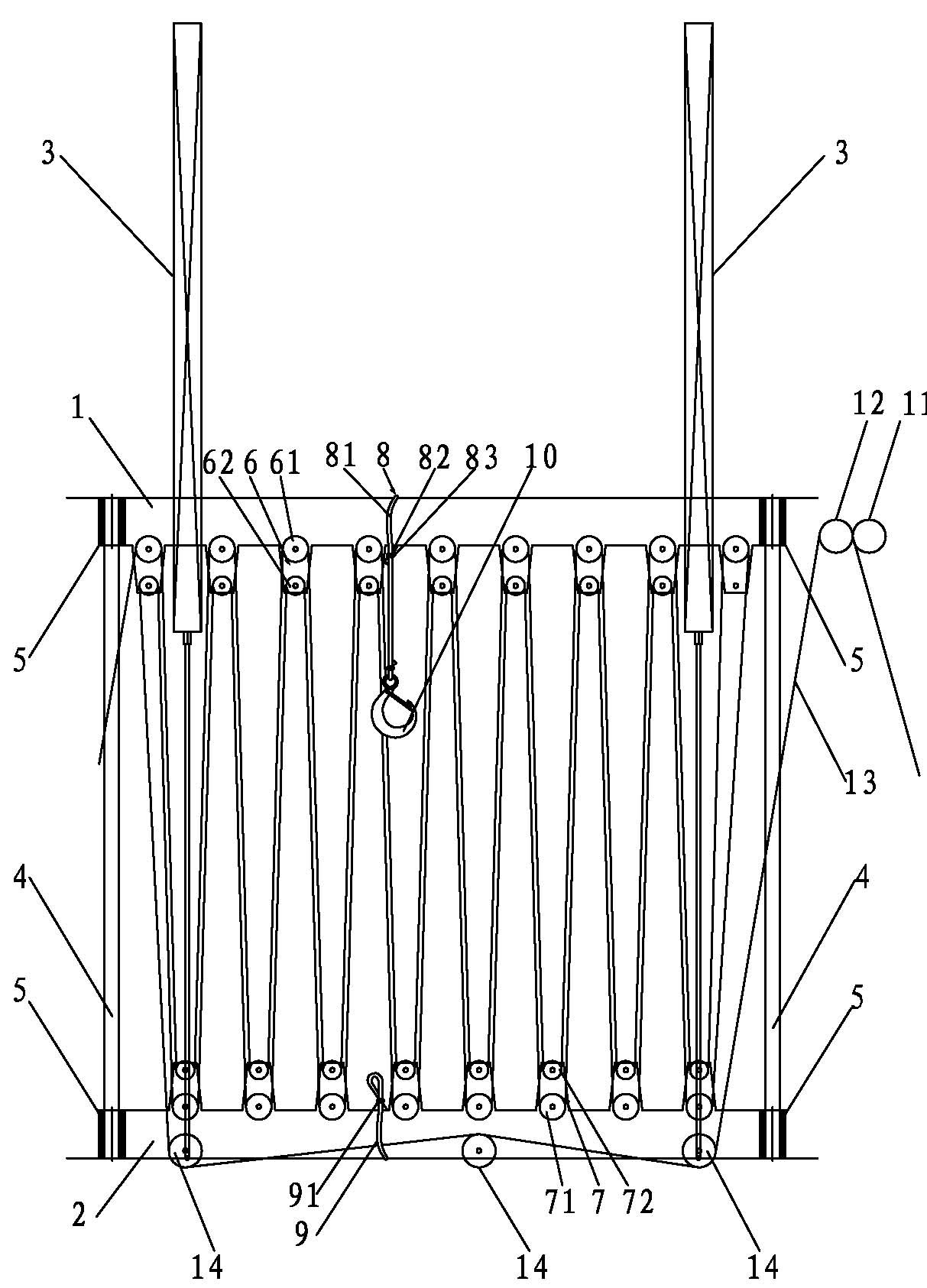

[0031] One of the specific implementations of an adjustable lifting cloth storage rack of the present invention, such as figure 1 As shown, it includes the upper frame 1 of the cloth storage rack, the lower frame 2 of the cloth storage rack, the telescopic cylinder 3 and the slide rod 4, the upper frame 1 of the cloth storage rack and the lower frame 2 of the cloth storage rack are connected by the telescopic cylinder 3, and the upper layer of the cloth storage rack The four corners of the frame 1 and the four corners of the lower frame 2 of the cloth storage rack are all provided with supports 3, and there are four slide bars 4, and each slide bar 4 is vertically arranged on the corresponding support 3, and Support the upper frame 1 of the cloth storage rack and the lower frame 2 of the cloth storage rack. A sliding bearing is arranged in the support 3, and the sliding bearing in the support 3 of the lower frame 2 of the cloth storage rack and the sliding rod 4 slide and coop...

Embodiment 2

[0041] The second specific embodiment of an adjustable lifting cloth storage rack of the present invention, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment are explained in embodiment 1, and in This will not be repeated here. The difference between this embodiment and Embodiment 1 is that the upper frame 1 of the cloth storage rack is provided with a first positioning piece 8, the first section 81 of the first positioning piece 8 is connected to the connecting piece 10, and the second section of the first positioning piece 8 The segment 82 is sheathed on the upper frame 1 of the cloth storage rack, and is fastened to the first segment 81 of the first positioning member through the first positioning buckle 83 . The position corresponding to the lower frame 2 of the cloth storage rack and the connector 10 is provided with a second positioning piece 9, the second positioning piece 9 is sleeved o...

Embodiment 3

[0044] The third specific embodiment of an adjustable lifting cloth storage rack of the present invention, the main technical solution of this embodiment is the same as that of Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 2, and are described in Embodiment 2. This will not be repeated here. The difference between this embodiment and Embodiment 2 is that the first positioning member 8 is an adjustable steel cable. The first positioning buckle 83 can select the steel cable positioning buckle. The second positioning member 9 is an adjustable steel cable. The second positioning buckle 91 can select the steel cable positioning buckle. The cost of the steel cable is relatively low and practical, and the position adjustment between the upper frame 1 of the cloth storage rack and the lower frame 2 of the cloth storage rack can be realized at a lower cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com