Sliding tube type air compressor

An air compressor and sliding tube technology, applied in the field of compressors, can solve the problems of poor cooling effect, less opportunities for exchanging heat, and more materials for making compressors, so as to achieve good cooling effect and favorable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

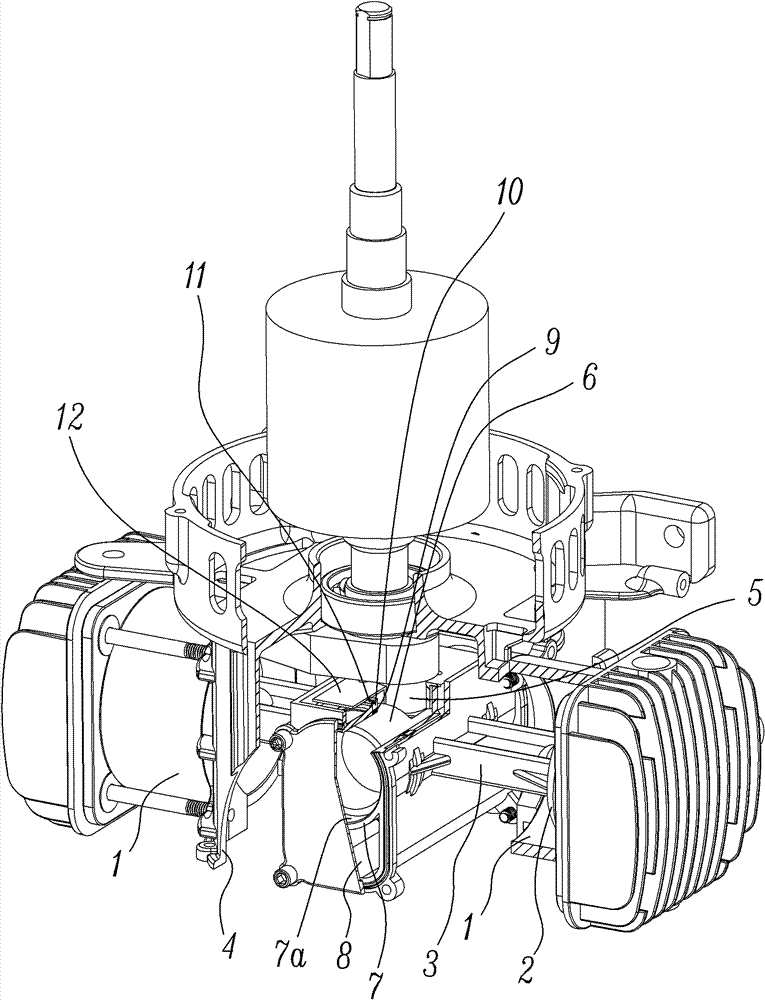

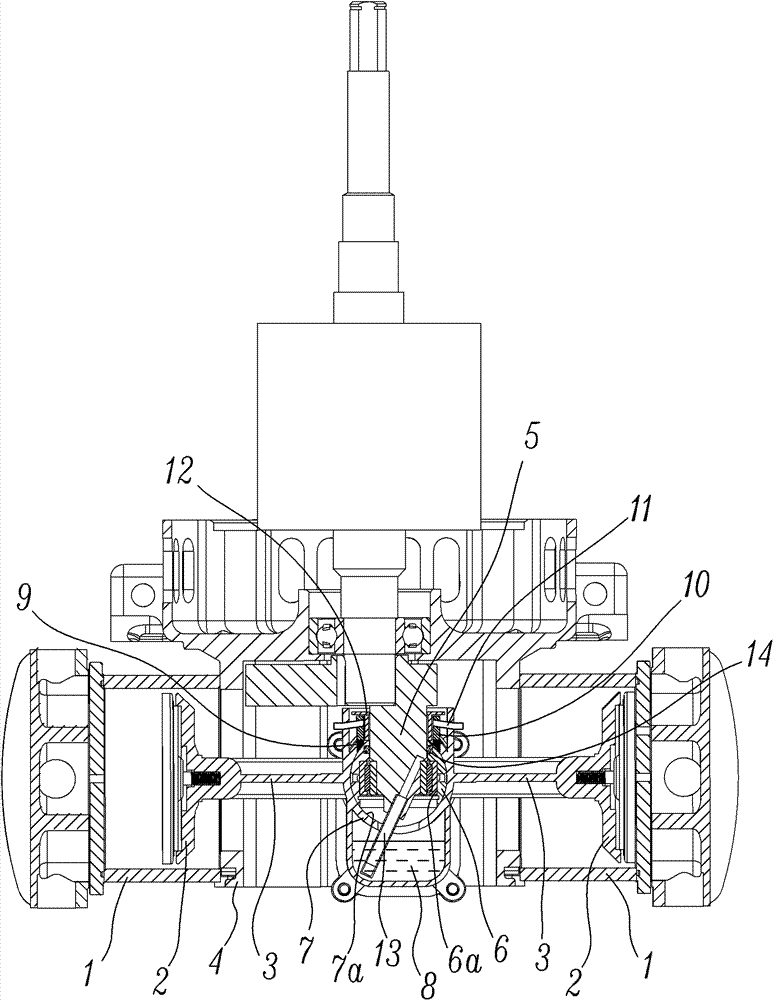

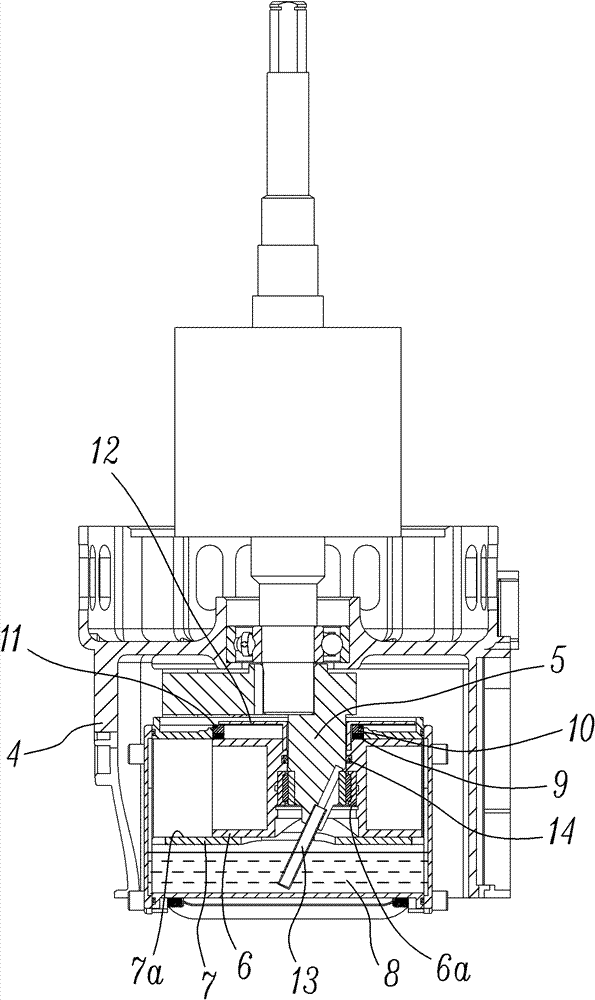

[0019] The present invention will be further described below with specific examples, see Figure 1 to Figure 3 :

[0020] A sliding tube air compressor, which includes a cylinder 1, a piston 2, a connecting rod 3, a crankcase 4, a crank pin 5, a sliding block 6 and a sliding tube 7. The cylinder 1 and the piston 2 each have two, so The connecting rod 3 and the piston 2 are tightly connected or they are made of an integrated structure, the connecting rod 3 is tightly connected to the sliding tube 7 or the connecting rod 3 and the sliding tube 7 are an integrated structure, and a seat is opened on the slider 6. Hole 6a, the slide tube 7 has a slideway 7a, the slide block 6 is arranged in the slideway 7a of the slide tube 7 and slidably fits with the slideway 7a, and the crank pin 5 is inserted into the seat hole 6a of the slide block 6 And directly rotate with the seat hole 6a (not shown in the figure) or rotate with the seat hole 6a through a bearing (as shown in the figure); the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com