Homopolar type radial magnetic suspension bearing and manufacturing method thereof

A magnetic suspension bearing and bearing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of the need for molds, manufacturing precision machining accuracy limitations, and high manufacturing costs, and achieve high manufacturing accuracy, small surface eddy currents, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

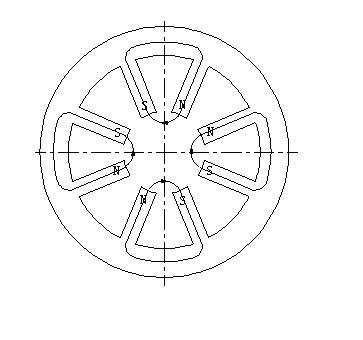

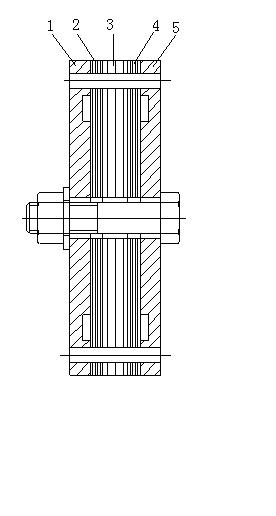

[0031] Such as figure 2 As shown, a homopolar radial magnetic suspension bearing includes a first pressure plate 1, a first bearing lamination 2, several connection laminations 3, a second bearing lamination 4, a second pressure plate 5, and a connection lamination 3. The first bearing stack 2 and the second bearing stack 4 are respectively arranged on both sides, the first pressure plate 1 is arranged on the outside of the first bearing stack 2, the second pressure plate 5 is arranged on the outside of the second bearing stack 4, the first bearing stack The sheets 2 and the second bearing laminations 4 are arranged with different poles, and the first bearing laminations 2 and the second bearing laminations 4 are arranged with the same poles.

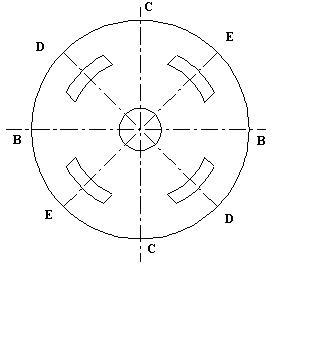

[0032] Such as image 3 As shown, four annular grooves are evenly arranged on the connecting lamination 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com