Novel variable-speed operating valve

A variable speed control valve, a new type of technology, applied in the direction of fluid pressure actuators, toothed components, clutches, etc., can solve the problem of rough clutch combination at the moment of gear shifting, unreasonable structure of the variable speed control valve, and deformation amplitude of the pressure regulating spring Large value and other problems, to achieve the effect of reducing the deformation amplitude and fatigue strength, improving reliability and service life, and overcoming shift lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

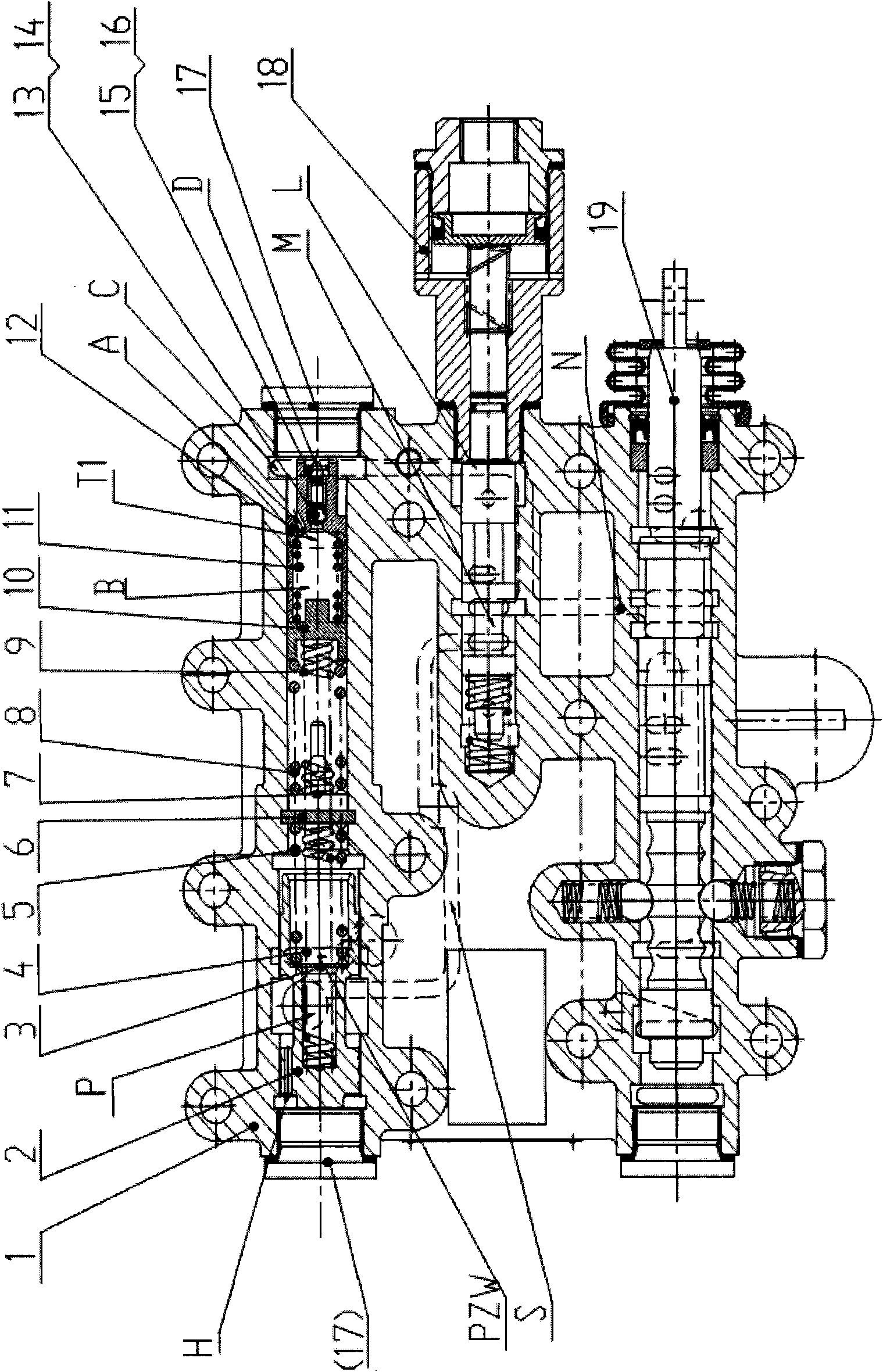

[0010] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0011] Refer to attached figure 1 , the novel variable speed control valve of the present invention comprises a valve body 1, a shut-off valve 18 and a distributing valve 19 that the original variable speed control valve possesses, and is characterized in that an overflow valve is also provided on the same axis of the same valve body 1. The flow valve and the buffer valve are separated by a locking plate 6 and communicated with another oil circuit.

[0012] The overflow valve is composed of an overflow spool 2, a pressure regulating gasket 3, a pressure regulating spring 4 and 5, and a screw plug 17. The overflow spool 2 placed in the corresponding hole of the valve body 1 is dumbbell-shaped in shape. There are two coaxial stepped blind holes with large and small diameters in the axial direction on the right end, and there are two coaxially set p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com