High speed burner for combustion chamber with film cooling type corrugated shell structure

A high-speed burner and shell structure technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of short service life and achieve the effects of improving service life, improving heat exchange effect, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

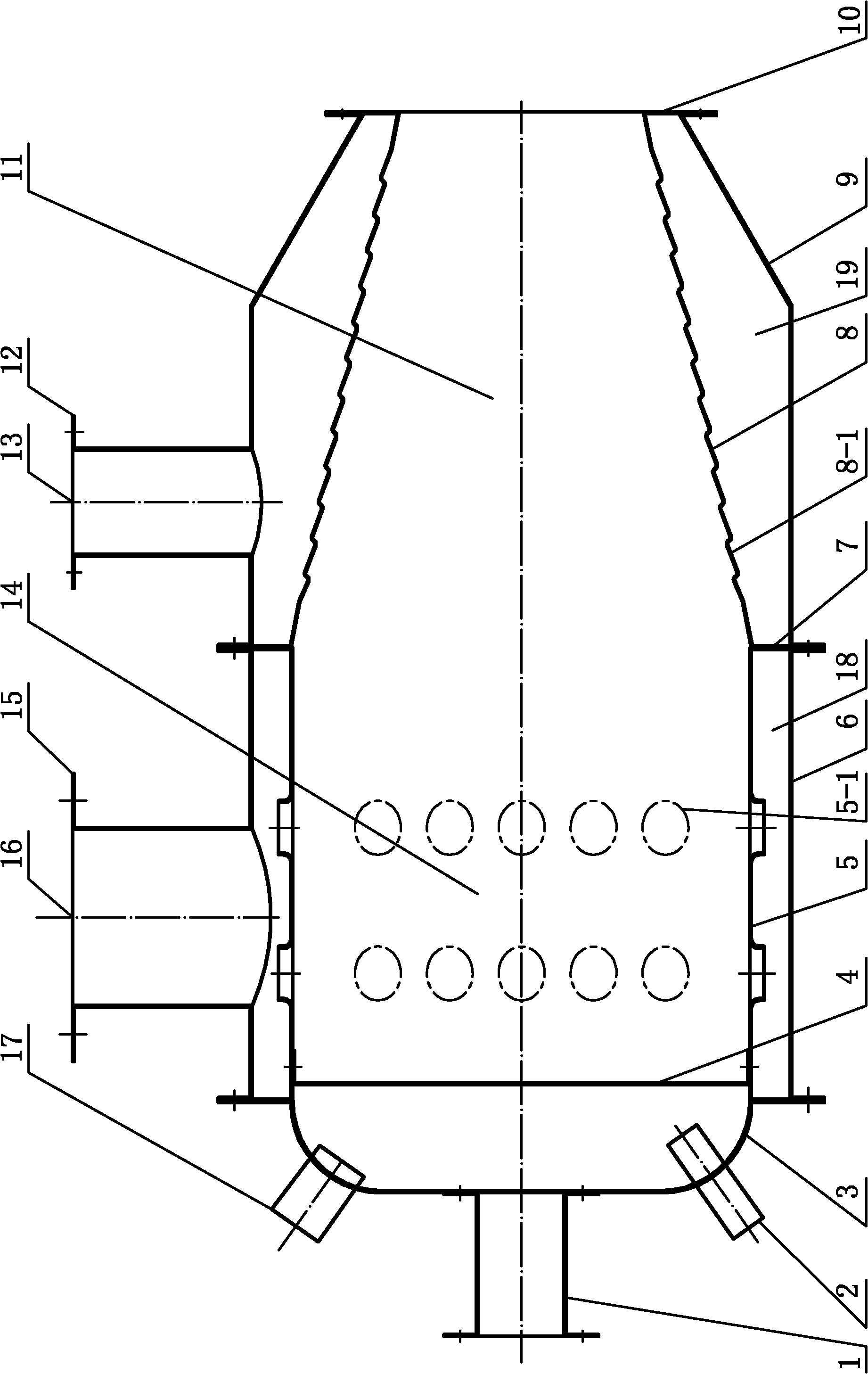

[0011] Specific implementation mode one: as Figure 1-9 As shown, the film-cooled corrugated shell structure combustion chamber high-speed burner described in this embodiment includes a high-speed burner end cover 3, a combustion chamber cylinder 5, a combustion chamber cylinder outer cover 6, and a combustion chamber housing 8 , gas inlet 1 and combustion-supporting air inlet 16, and the burner also includes a combustion chamber casing cover 9 and a secondary air inlet 13; the combustion chamber casing 8 is a conical casing whose side wall is corrugated, and the combustion chamber The longitudinal section of the side wall of the housing 8 has a corrugated structure; the combustion chamber housing 8 is uniformly distributed with a plurality of film cooling holes 8-1 (through holes); One end of the indoor cylinder 5, the other end of the combustion chamber 5 communicates with the large end of the combustion chamber shell 8, the gas inlet 1 communicates with the high-speed burne...

specific Embodiment approach 2

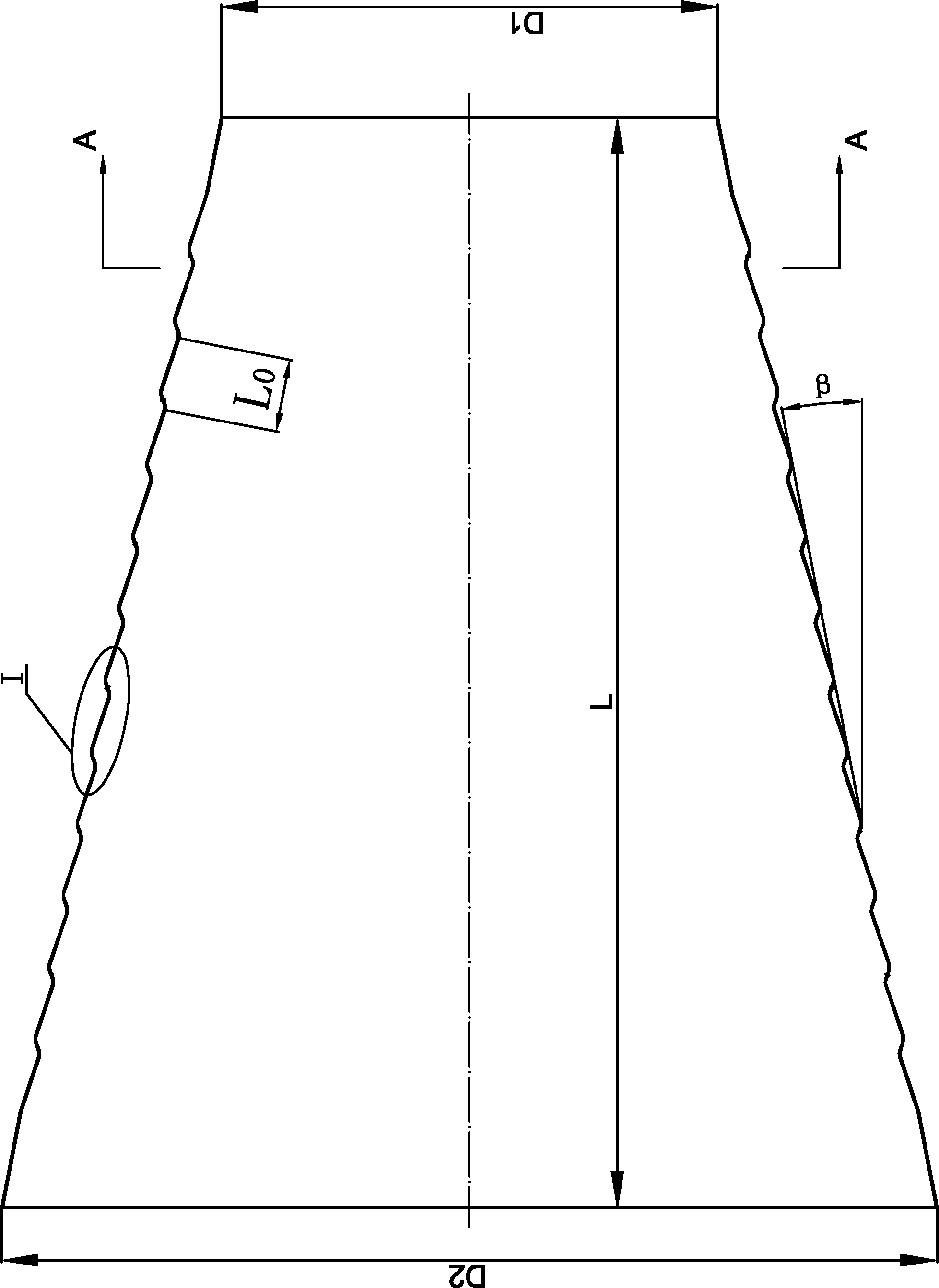

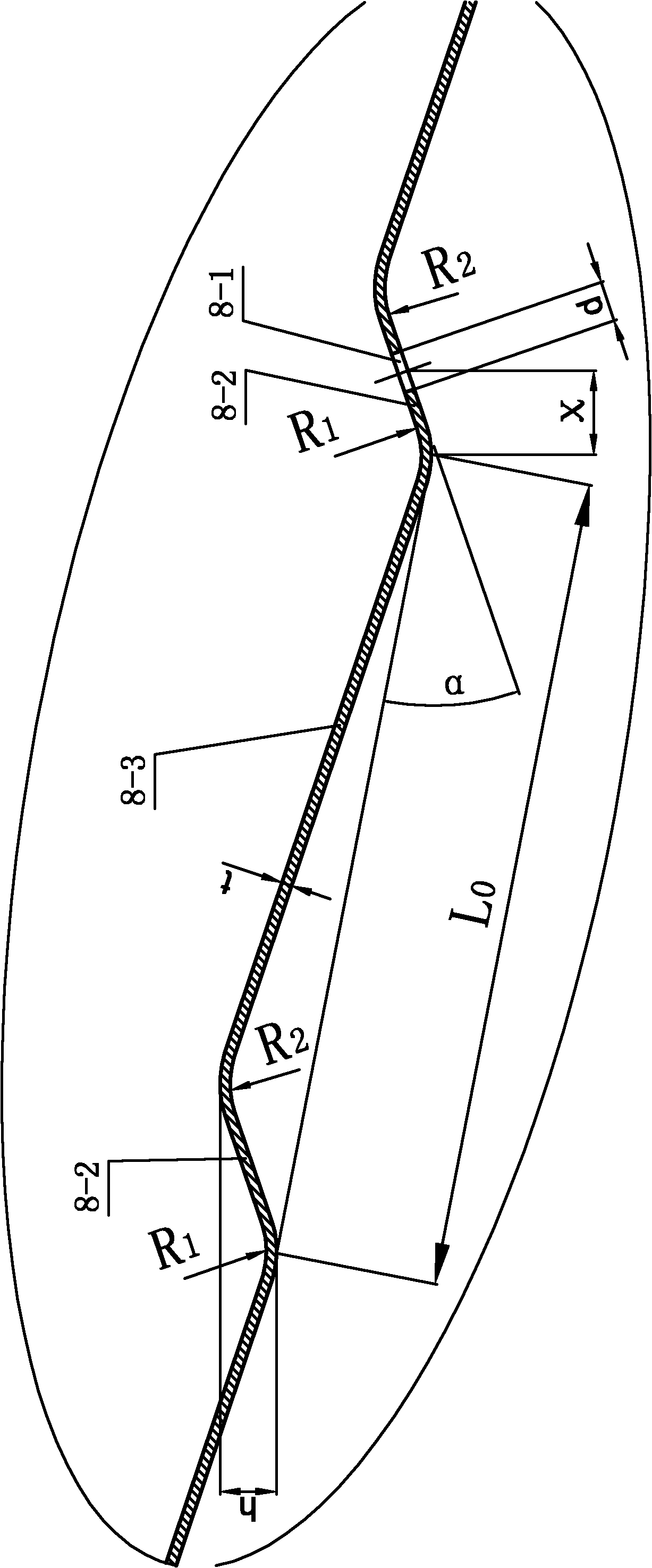

[0017] Specific implementation mode two: as Figure 2~3 As shown, the longitudinal section of the side wall of the combustion chamber housing 8 in this embodiment is formed by sequentially connecting n sections of single-section corrugations, and each single-section corrugation is composed of short corrugations 8-2 and long corrugations 8-3, each Length L of single corrugation 0 The corrugation angle α of each single-section corrugation is 25°-45°, the corrugation height h of each single-section corrugation is 2.0mm-3.0mm; the number of corrugated sections n of the combustion chamber shell 8 is determined by the single section Corrugation length L 0 and the total length L of the combustion chamber. The above parameters are all related to the cooling effect of the combustion chamber shell. The combustion chamber shell adopts a metal corrugated conical shell with film cooling holes. The corrugated structure increases the rigidity of the combustion chamber shell, and has good ...

specific Embodiment approach 3

[0018] Specific implementation mode three: as Figure 2~3 As shown, in this embodiment, the inward concave transition fillet radius R between the adjacent short corrugated ribs 8-2 and the long corrugated ribs 8-3 1 1.5mm to 2.5mm, the outwardly convex transition fillet radius R between adjacent short corrugations 8-2 and long corrugations 8-3 2 2.0mm to 2.5mm. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com