High temperature-resistant ceramic cremation kang surface

A technology of high-temperature-resistant ceramics and kang surface, which is applied to the methods of incinerating corpses, burning methods, and burning types, etc., which can solve problems such as easy cracks, uneven oxygen supply, and failure to use normally, and achieve good mechanical properties, strength, and good The effect of thermal shock stability and reasonable structure arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

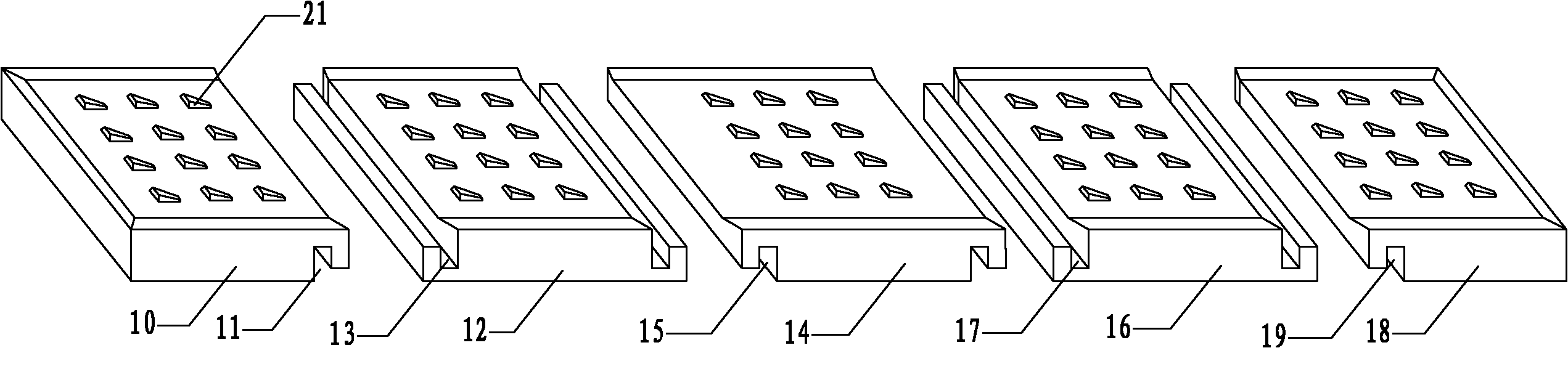

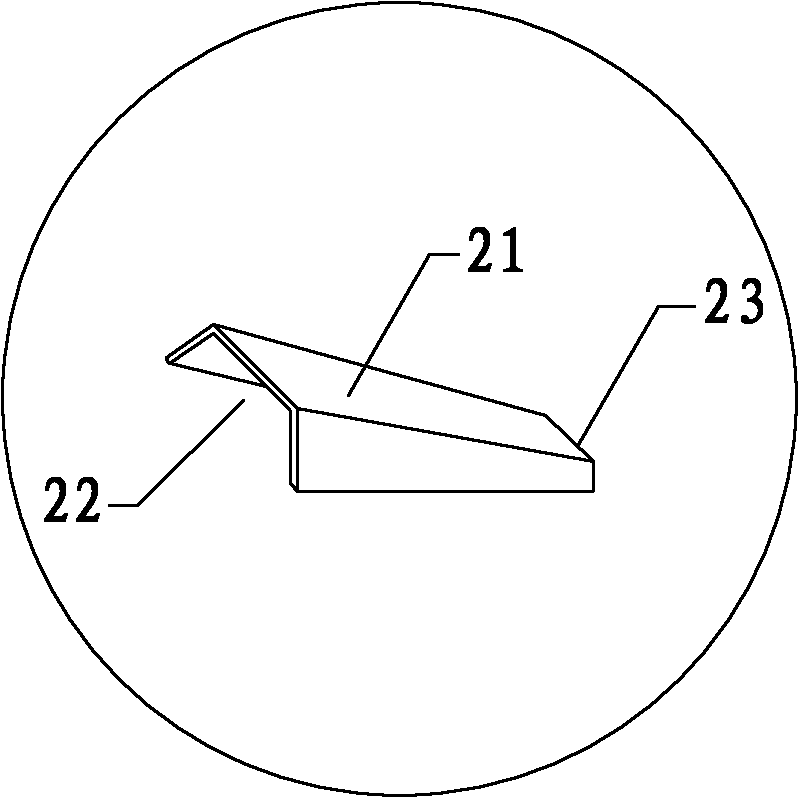

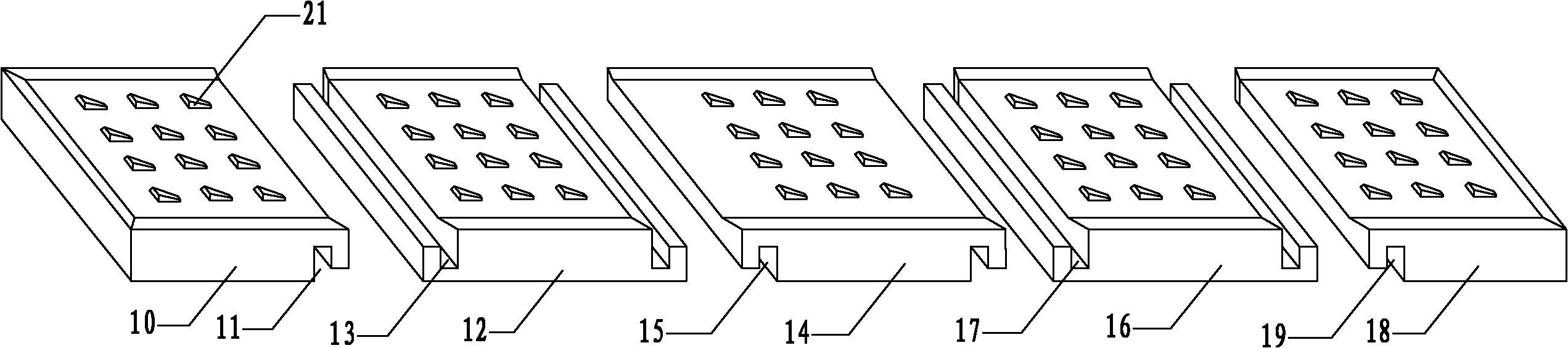

[0021] Such as figure 1 Shown is the structural representation of the high temperature resistant ceramic cremated kang surface in the present invention. The high-temperature-resistant ceramic heated kang surface of the present invention comprises: a kang body group and ventilation groove 21, and the kang body group is made up of a plurality of kang bodies, and the kang body is a rectangular shape, and the quantity of the kang body is generally: 3 pieces, 4 pieces according to actual needs blocks or 5 blocks. Ventilation groove 21 is arranged on the upper surface of Kang body. The Kang face of the present invention is made of ceramic material.

[0022] The number of kang bodies in this preferred embodiment is 5 pieces, respectively the first kang body 10, the second kang body 12, the third kang body 14, the fourth kang body 16 and the fifth kang body 18 are connected in sequence. A first kang body fixing groove 11 is opened at the edge of the lower surface of the first kang ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com