High-performance mullite castable and preparation method thereof

A castable and mullite technology, which is applied in the field of high-performance mullite castables and their production, can solve the problems of low refractoriness and softening temperature under load, structural spalling, and low content of main components, and achieve thermal shock stability. Good performance, increased service life, good volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh 65 kg of fused mullite aggregate (grain size is 0-15mm, aluminum oxide content is greater than 70%, silicon dioxide content is greater than 26%), white corundum powder (grain size is 200 mesh, Aluminum content greater than 99%) 15 kg, zirconium silica powder (silica content greater than 92%, zirconia content greater than 3%) 5 kg, calcined alumina fine powder (particle size is 325 mesh, aluminum oxide content greater than 98.5%) ) 5 kg, fused pure calcium aluminate cement (alumina content greater than 70%) 3 kg, kyanite powder (alumina content greater than 57%) 2.5 kg, sillimanite powder (alumina content greater than 58%) 2.5 kg, zircon powder (325 mesh in particle size, zirconia content not less than 65%) 2 kg, nano calcium carbonate powder (particle size 25-100 nm, calcium carbonate content greater than 90%) 0.2 kg, 0.2 kg of polycarboxylate superplasticizer;

[0029] 2) Mix the powder with a powder mixer for more than 3 minutes until uniform.

[0030] 3) P...

Embodiment 2

[0032] 1) Weigh 68 kg of fused mullite aggregate, 13 kg of white corundum powder, 4 kg of zirconium silicon powder, 5 kg of calcined alumina powder, 3 kg of fused pure calcium aluminate cement, 2.5 kg of kyanite powder, silicon 2.5 kg of thread stone powder, 2 kg of zircon powder, 0.2 kg of nano-calcium carbonate powder, and 0.2 kg of polycarboxylate superplasticizer;

[0033] 2) According to the method of Example 1, 100 kg of this high-performance mullite castable was prepared.

Embodiment 3

[0035] 1) Weigh 70 kg of fused mullite aggregate, 12 kg of white corundum powder, 4 kg of zirconium silicon powder, 4 kg of calcined alumina powder, 3 kg of fused pure calcium aluminate cement, 2.5 kg of kyanite powder, silicon 2.5 kg of thread stone powder, 2 kg of zircon powder, 0.2 kg of nano-calcium carbonate powder, and 0.2 kg of polycarboxylate superplasticizer;

[0036] 2) According to the method of Example 1, 100 kg of this high-performance mullite castable was prepared.

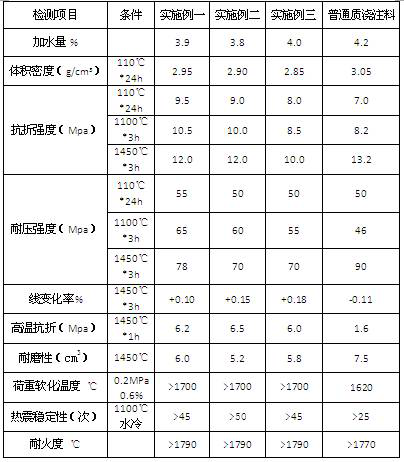

[0037] According to this formula and configuration method, the prepared castables are vibrated and molded to make a 40×40×160mm strip test block, dried at 110°C for 24 hours, and then fired at 1450°C×1 hour in the air to measure the high temperature resistance. Flexural strength; after firing at 1450°C for 3 hours, measure its bulk density, apparent porosity, flexural strength, linear change rate and mass change rate. Compared with ordinary castables, the results are as follows:

[0038]

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com