Water mist collector of cooling tower

A technology of cooling towers and concentrators, applied in the direction of water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve problems such as water vapor and water resource loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

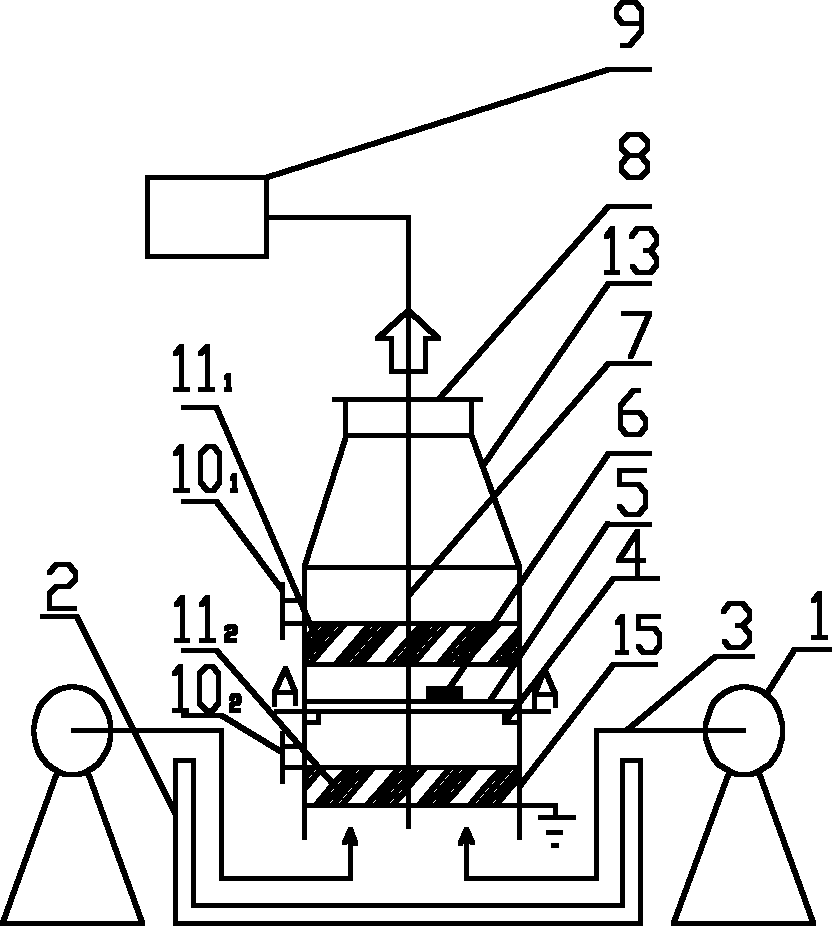

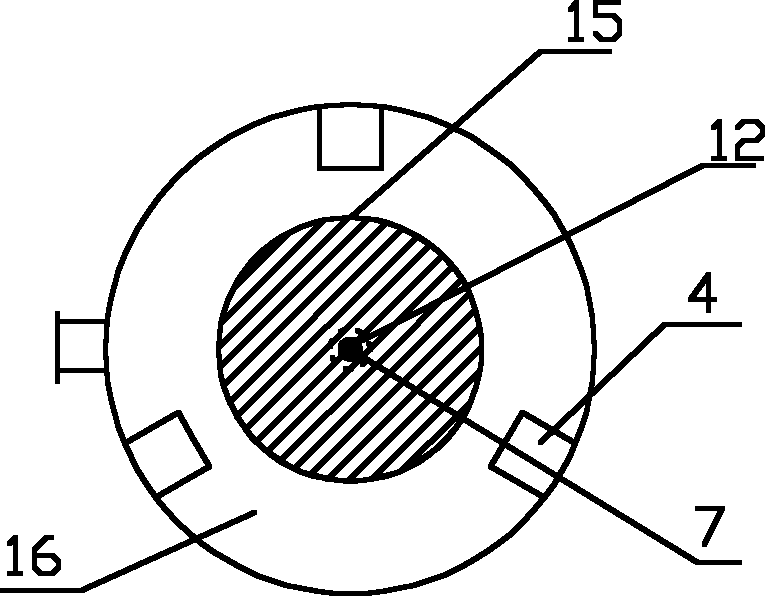

[0018] A cooling tower water mist collector, such as figure 1 , which is inside the cooling tower, the first wire mesh 11 1 installed in the first water inlet 10 1 Next, the second wire mesh 11 2 installed in the second water inlet 10 2 Next, on the first wire mesh 11 1 and a second wire mesh 11 2 Fixing frame 5 is installed between, ultrasonic generator 6 is installed on the mounting fixing frame 5, and is connected with power supply; The first wire mesh 11 1 and a second wire mesh 11 2 It is a cylinder with the same size and structure.

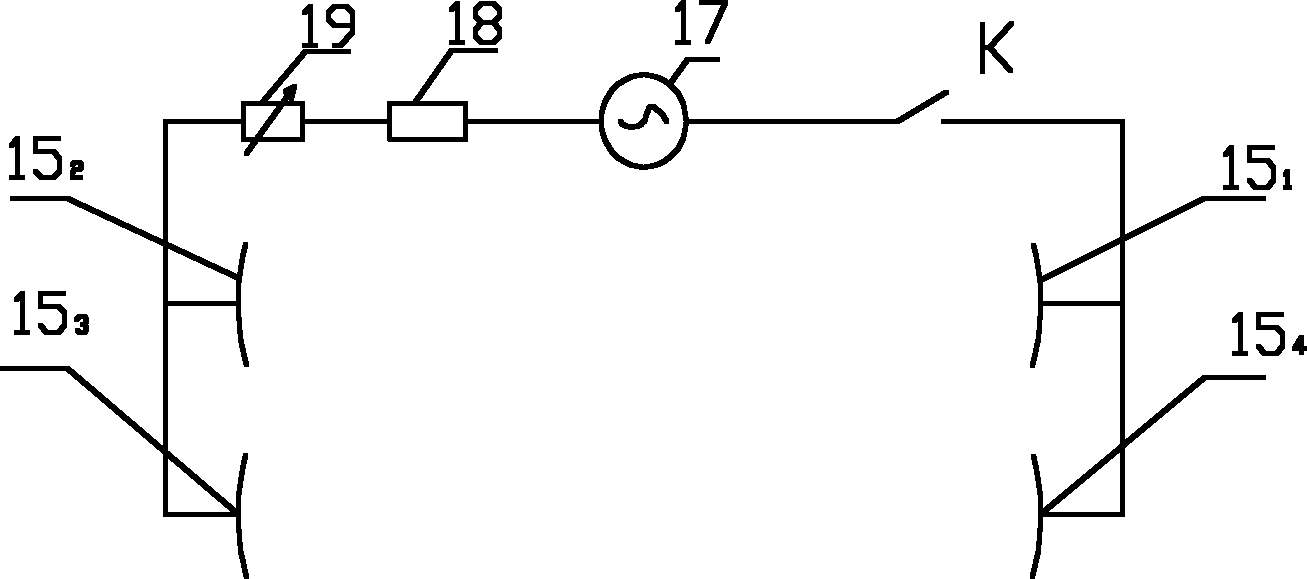

[0019] One end of the corona wire 7 passes through the first wire mesh 11 1 , fixed frame 5, the second wire mesh 11 2 Hanging at the center of the cooling tower, the other end of the corona metal wire 7 is connected to the pulse power supply, fixed on the top cover 8 of the cooling tower, and insulated from it.

[0020] fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com