Method for simulating work environment for testing high-temperature stability of plastic filler and special device thereof

A technology with high temperature stability and special equipment, applied in measuring equipment, analytical materials, thermal analysis of materials, etc., can solve the problems of reduced mass exchange effect, inconsistent deformation value of plastic packing, large bed resistance, etc., to achieve true and reliable measurement values , Consistent deformation and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

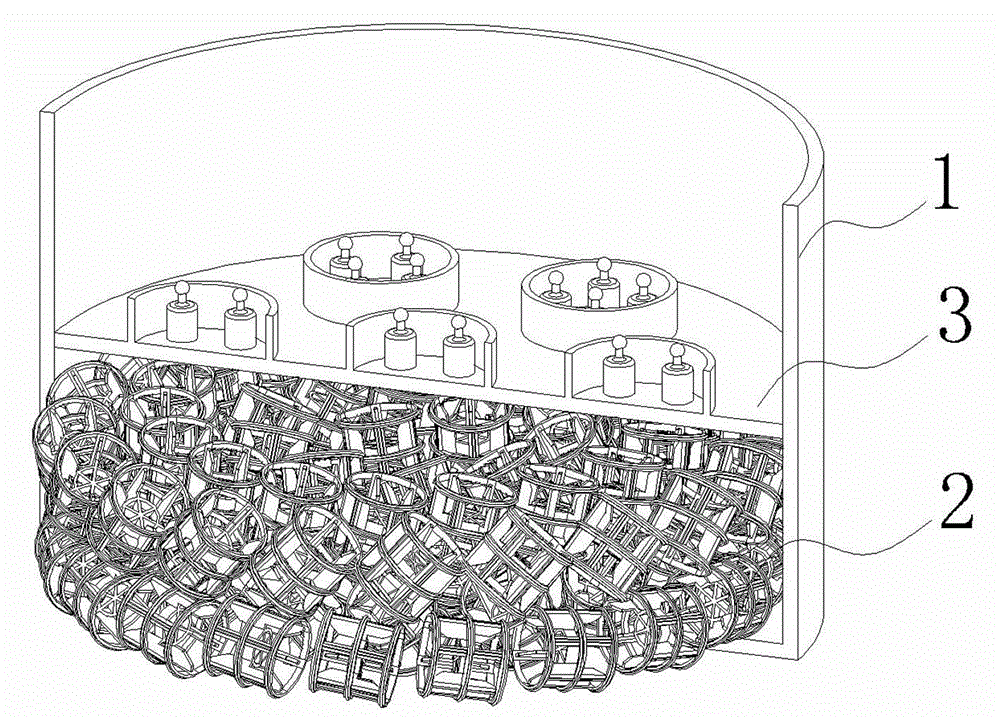

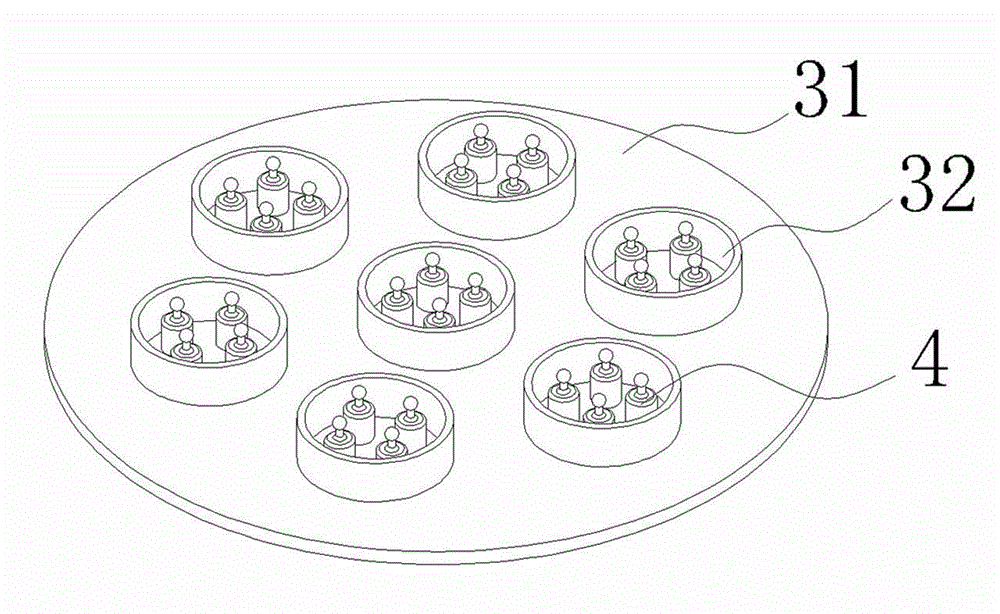

[0024] 2) Prefabricate a dedicated device 3, such as image 3 As shown, it comprises a horizontal pressing plate 31, and the horizontal pressing plate 31 is a circular steel plate with a diameter of 500 mm and a thickness of 10 mm. Accommodating grooves 32, the accommodating grooves 32 are circular steel cylinders welded vertically on the surface of the horizontal pressing plate 31, wherein one accommodating groove 32 is coaxially located in the middle of the horizontal pressing plate 31, and the other six accommodating grooves 32 are positioned around the central axis of the horizontal pressing plate 31 Evenly distributed in the circumference, four counterweights 4 of equal weight are respectively placed in the seven accommodation grooves 32, so that the special device 3 bears the same bed weight as the plastic packing to be tested, and then the special device 3 is placed in parallel On the surface of the plastic packing 2 inside the straight wall container 1;

[0025] 3) Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com