Slot waveguide micro-ring resonance type single-fiber three-dimensional machine

A waveguide micro-ring and micro-ring resonance technology, applied in the coupling of optical waveguides and other directions, can solve the problems of limited chip output, low integration, large size of tri-directional devices, etc., to achieve flexible use, improve integration, The effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

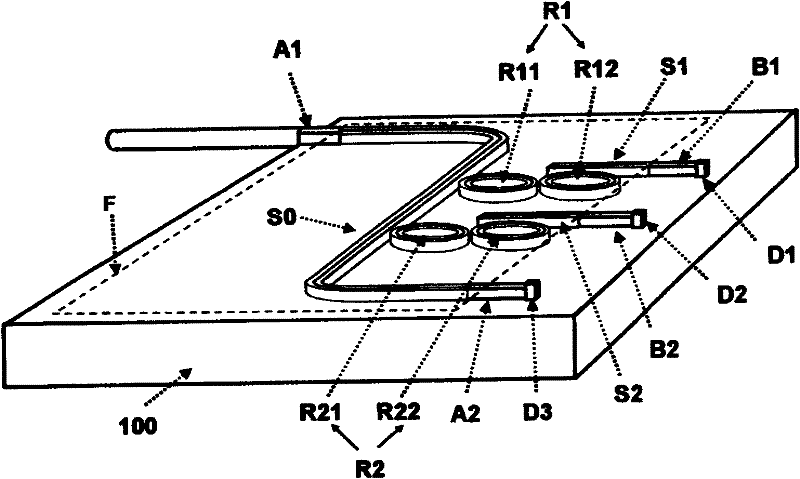

[0052] Embodiment 1, hybrid integration method: when the substrate 100 is silicon-on-insulator, the laser D3 , the first monitor detector D1 and the second monitor detector D2 are hybrid-integrated on the substrate 100 .

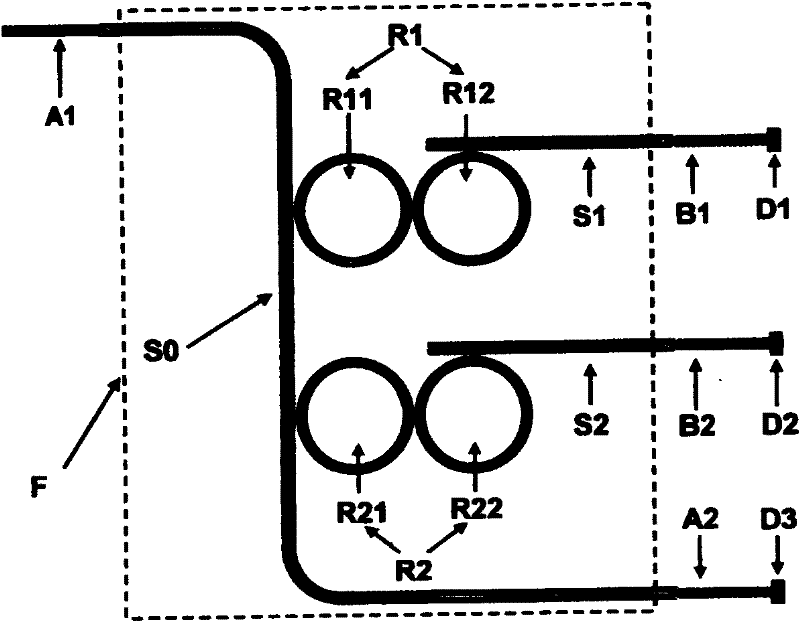

[0053] control figure 1 and figure 2 , the present invention adopts silicon-on-insulator (SOI) as the substrate 100, dry-etching on the substrate 100 to manufacture slot waveguide double micro-ring two-way filter F, the first input waveguide A1, the second input waveguide A2, the second input waveguide An output waveguide B1 and a second output waveguide B2, wherein the thickness of the silicon on the SOI layer is 320nm, the etching depth is 320nm, and the thickness of each involved waveguide is 320nm.

[0054] One main channel waveguide S0, the first waveguide double microring R1, the second waveguide double microring R2 included in the slot waveguide double microring two-way filter F, the first downloading waveguide S1 and the second downloading waveguid...

Embodiment 2

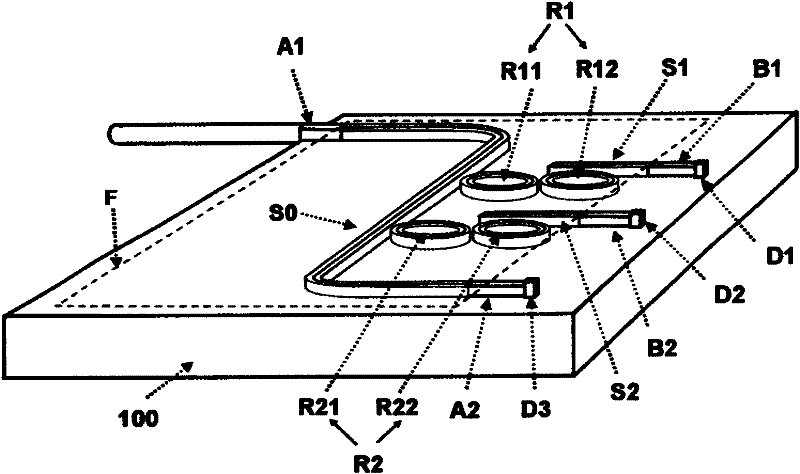

[0066] Embodiment 2, monolithic integration method:

[0067] Among them, the substrate 100 selects the III-V-OI formed by bonding the InP / InGaAsP substrate and the surface of the oxidized silicon wafer under high temperature annealing at 500°C as the substrate, the laser D3 uses an InP laser, the first monitoring detector D1 and the second The monitoring detectors D2 are all InGaAsP detectors, which are directly fabricated on the substrate 100 .

[0068] control figure 1 and figure 2 , the present invention uses a III-V-OI formed by bonding an InP / InGaAsP substrate and an oxidized silicon wafer surface at a high temperature as the substrate 100 . Dry etching on the substrate 100 to fabricate a slot waveguide double microring two-way filter F, the first input waveguide A1, the second input waveguide A2, the first output waveguide B1, the second output waveguide B2, where III-V- The thickness of the InGaAsP waveguide on the OI upper layer is 320nm, the etching depth is 320nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com