Piezoelectric element and preparation method thereof

一种压电元件、条件的技术,应用在电气元件、压电/电致伸缩器件的制造/组装、压电/电致伸缩/磁致伸缩器件等方向,达到拓宽应用领域的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The piezoelectric element 100 of the embodiment of the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

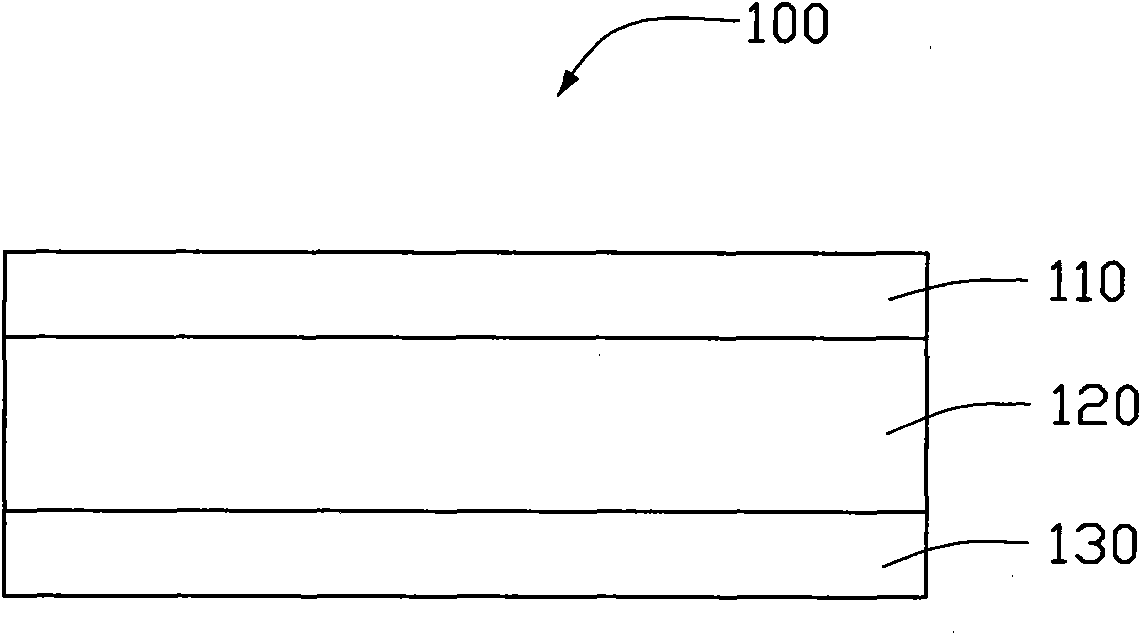

[0015] see figure 1 , the embodiment of the present invention provides a piezoelectric element 100 , which includes a polymer layer 120 , a first metal layer 110 and a second metal layer 130 . The polymer layer 120 has two opposite surfaces, and the first metal layer 110 and the second metal layer 130 are respectively arranged on the two opposite surfaces of the polymer layer 120 to form a three-layer laminated structure. The material layer 120 is disposed between the first metal layer 110 and the second metal layer 130 .

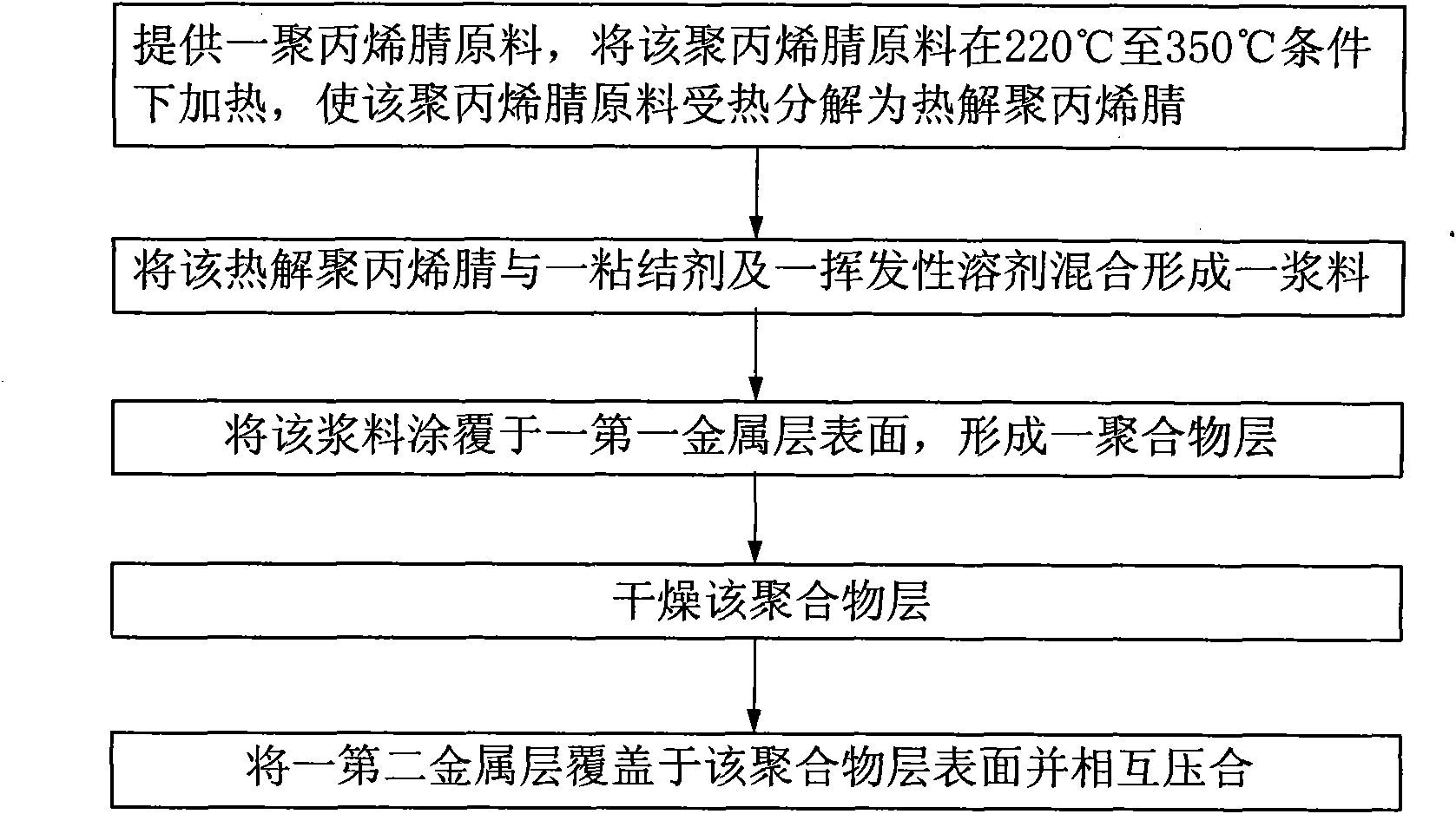

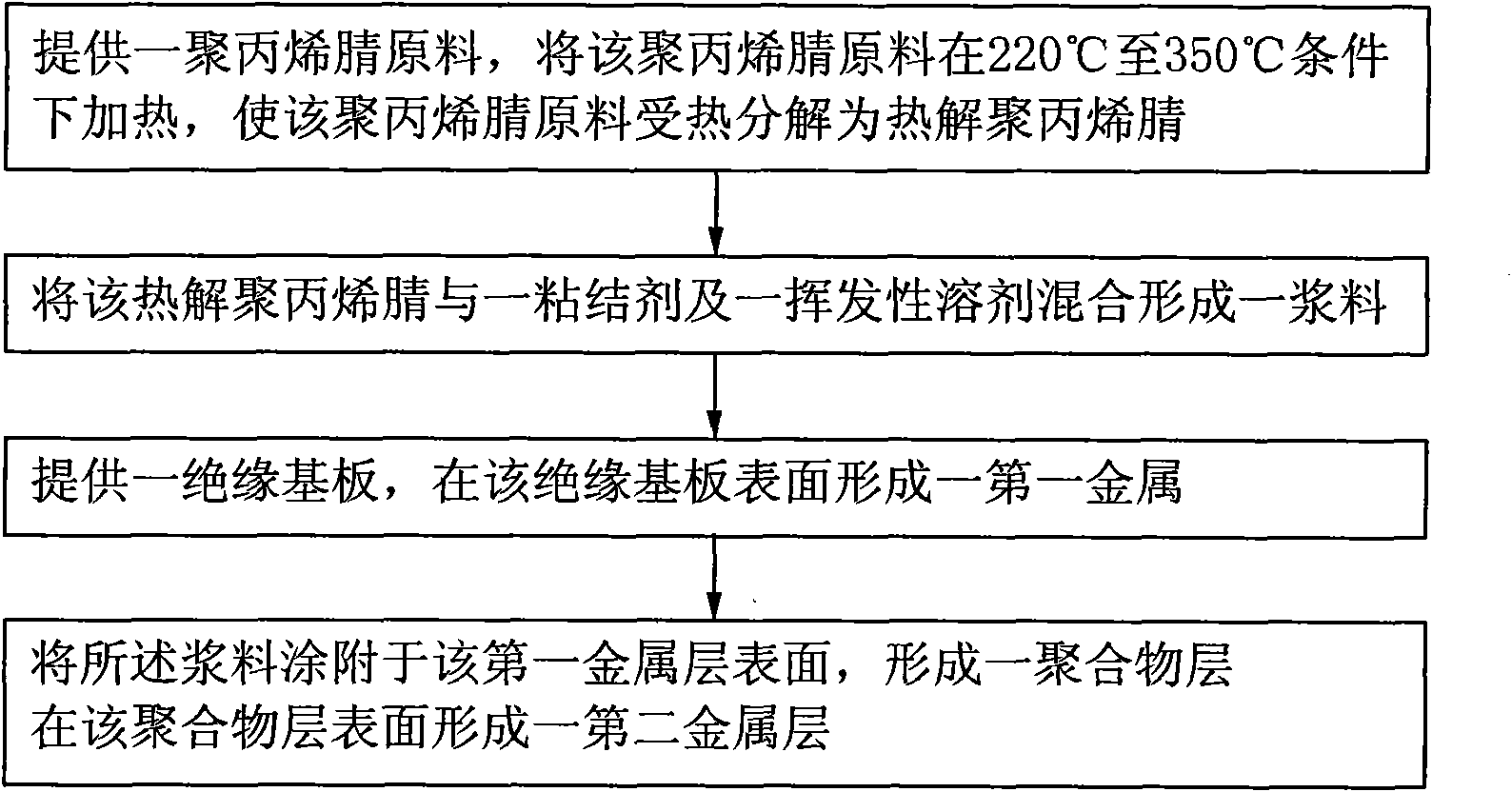

[0016] The main material of the polymer layer 120 is pyrolytic polyacrylonitrile (PPAN). The pyrolyzed polyacrylonitrile is obtained by heating polyacrylonitrile below 350° C. for a certain period of time. Due to the action of heating, the molecular chains in the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com