Method and apparatus for fabricating a fibre reinforced thermoplastic composite structure

A thermoplastic and fiber-reinforced technology, applied in chemical instruments and methods, transportation and packaging, climate sustainability, etc., can solve the problems that ultrasonic tape laying cannot be realized in an effective and rapid manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

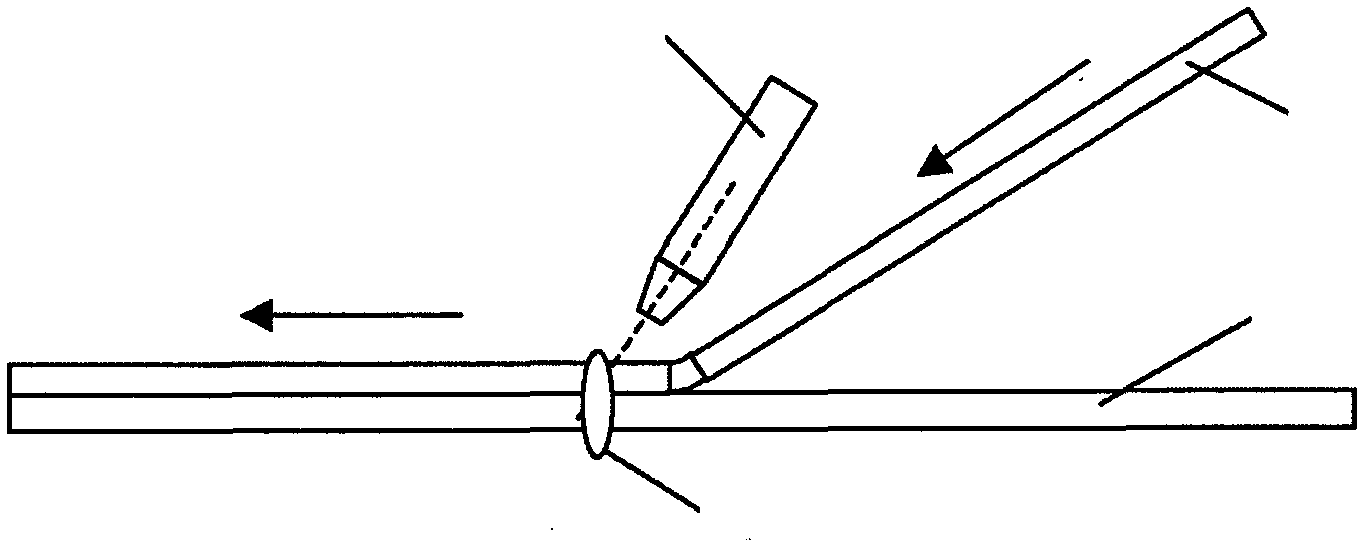

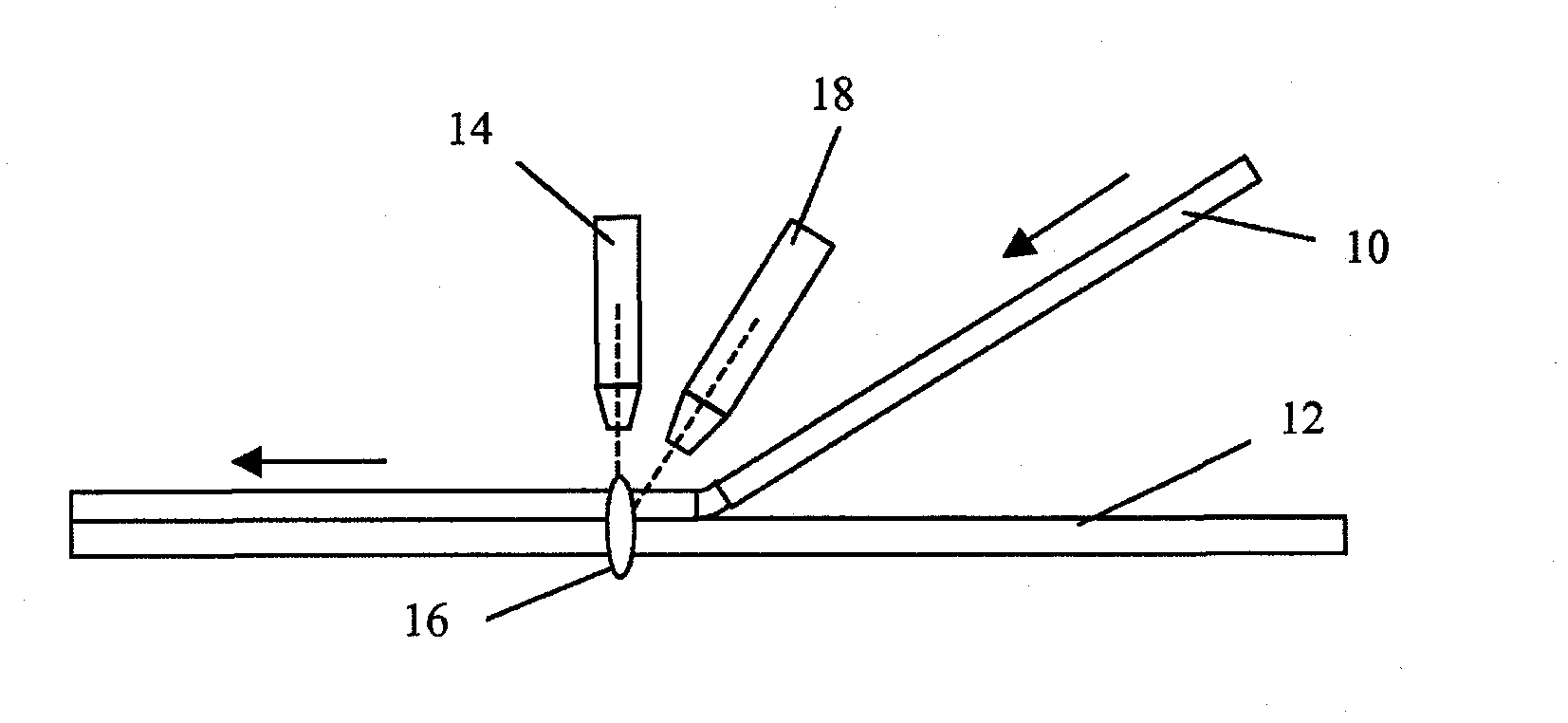

[0019] Referring to FIG. 1 , a typical apparatus for performing ultrasonic tape laying of thermoset composite materials is schematically shown. An upper layer 10 of thermoset tape is placed over an existing lower layer 12 of thermoset composite material. The lower layer 12 may be a single layer of thermoset tape material or may be a stack of multiple layers that have been previously deposited. Ultrasonic transducers 14 are positioned to introduce ultrasonic energy into the upper and lower layers of thermoset composite material within circled portions 16 shown in FIG. 1 . The upper and lower layers of the thermosetting composite material move relative to the ultrasonic transducer 14 in the direction shown in FIG. The point above the lower layer 12 of material.

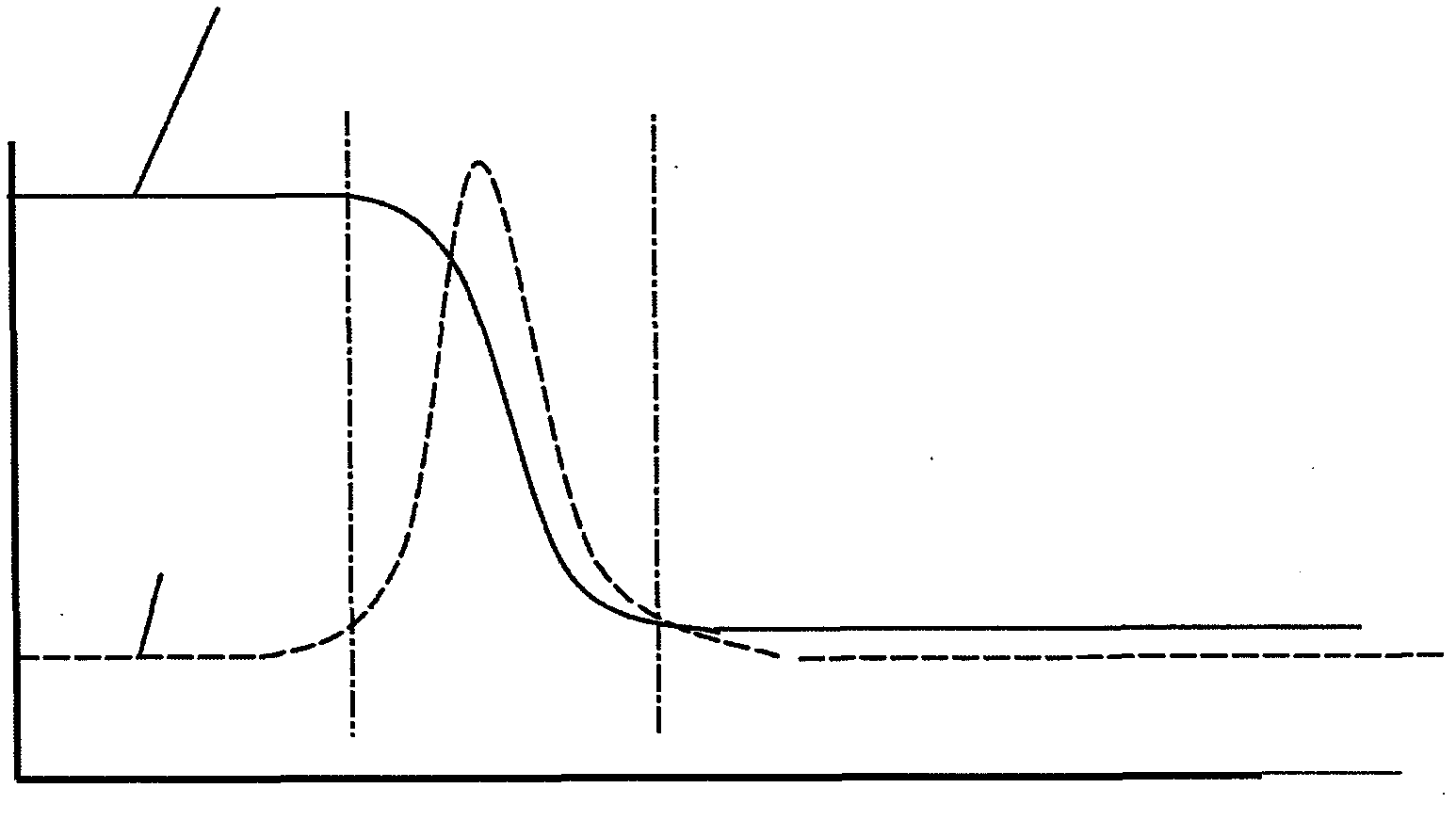

[0020] Ultrasonic curing of thermoset composites occurs through the following mechanism and can be referred to figure 2 State the key features of material relevant to the institution, figure 2 Schematically showing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com