Integrated adult diaper cotton core transferring and compacting device and transferring and compacting method

An all-in-one, cotton-core technology, applied in medical science, bandages, etc., can solve the problems of high production cost, unstable product quality, low production efficiency, etc., and achieve the effect of stable product quality, saving money and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

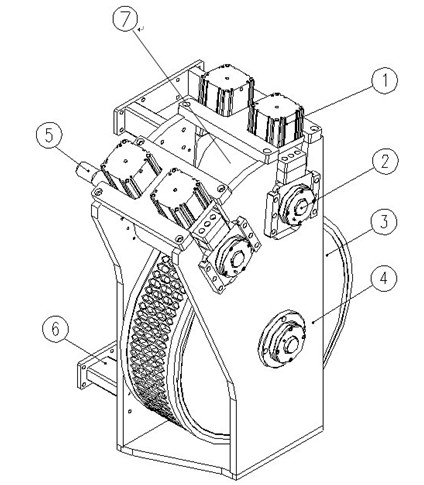

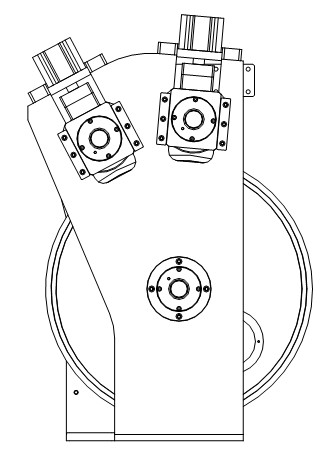

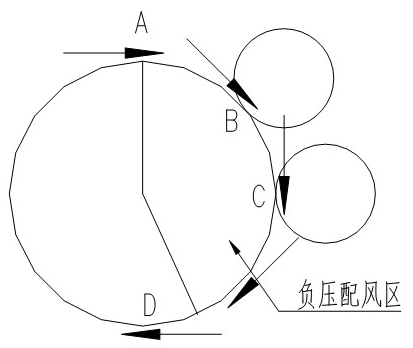

[0011] Embodiment 1: with reference to attached Figure 1-3 . An integrated device for transfer and compaction of adult diaper cotton core, which includes a mounting frame 4, a transfer wheel 3 is arranged inside the mounting frame 4, two embossing assemblies 2 are arranged above the transfer wheel 3, and an embossing assembly 2 is arranged above the embossing assembly 2 There is a pressurizing device 1, and the side of the installation frame 4 is provided with a negative pressure adsorption assembly 5, which cooperates with the transfer wheel 3 and makes a part of the transfer wheel 3 in a negative pressure area. The surface of the embossing roller 7 in the embossing assembly 2 is provided with concavo-convex patterns. The working side of the transfer wheel 3 compacting the cotton core is a negative pressure air distribution area. Two fixing frames 6 are arranged on the side of the mounting frame 4 . The pressurizing device 1 is a cylinder pressurizing device. That is to ...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the adult diaper cotton core is transferred and compacted. When the transfer wheel 3 is transferred downward from the vertical upper point, the core material formed by the device will be absorbed by negative pressure. When the surface of the transfer wheel assembly 3 is driven by the rotation of the transfer wheel 3 to pass through less than half a circle, the core material is compacted by the embossing assembly 2 pressurized by the pressurizing device 1, so that the core material has enough At the same time, different patterns made on the roller body of the embossing component form concave and convex patterns on the surface of the core material. After compaction, the core material will have strong water absorption and good ability to prevent faults. After hardening, the core material continues to be adsorbed on the surface of the transfer wheel 3 and rotates. When the lower point is about to be reached, the negative pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com