Packaging device of shell-free capacitor

A packaging device and capacitor technology, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems affecting product performance, affecting capacitor shock/vibration resistance and self-heating, and epoxy resin can not be fully filled, etc., to improve the quality of finished products, Overcome the effect of not fully filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but the description of the embodiments is not a limitation on the technical solution, and any changes in form but not in substance according to the concept of the present invention should be regarded as the protection scope of the present invention.

[0020] In the following descriptions, all concepts related to the directionality (or orientation) of up, down, left, right, front and rear are for the position state of the picture being described, and the purpose is to facilitate public understanding , so it cannot be understood as a special limitation on the technical solution provided by the present invention.

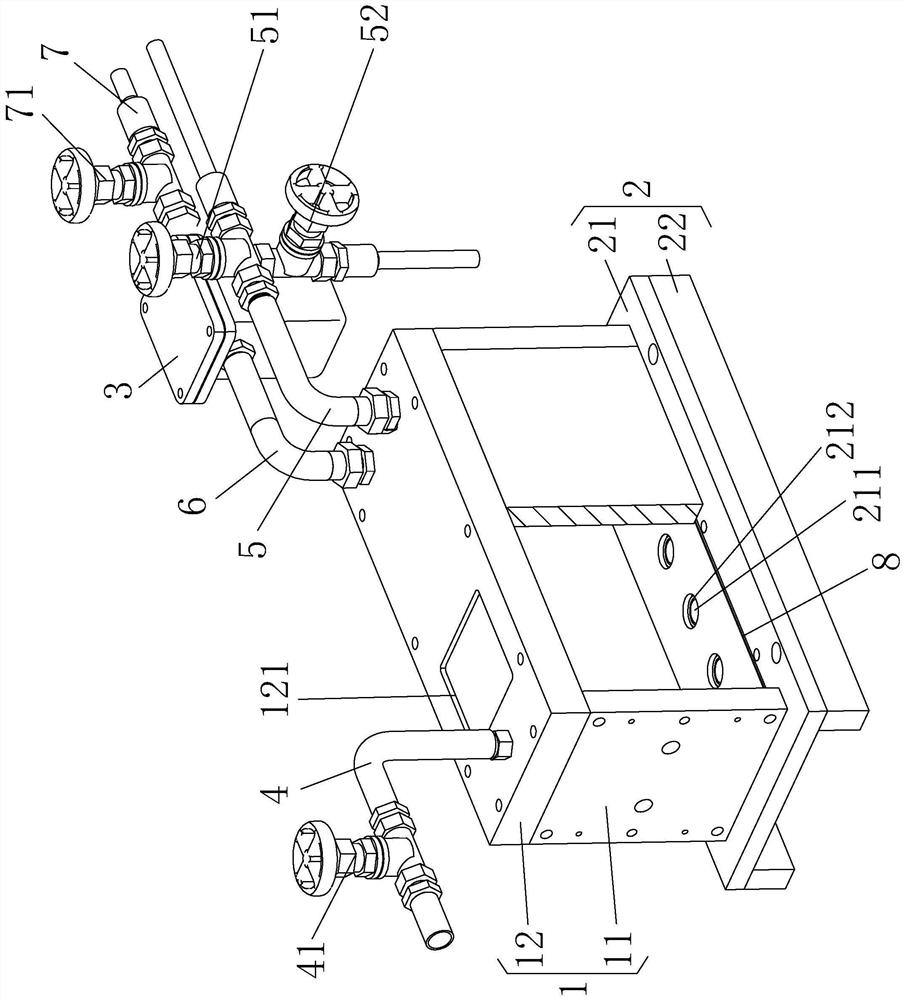

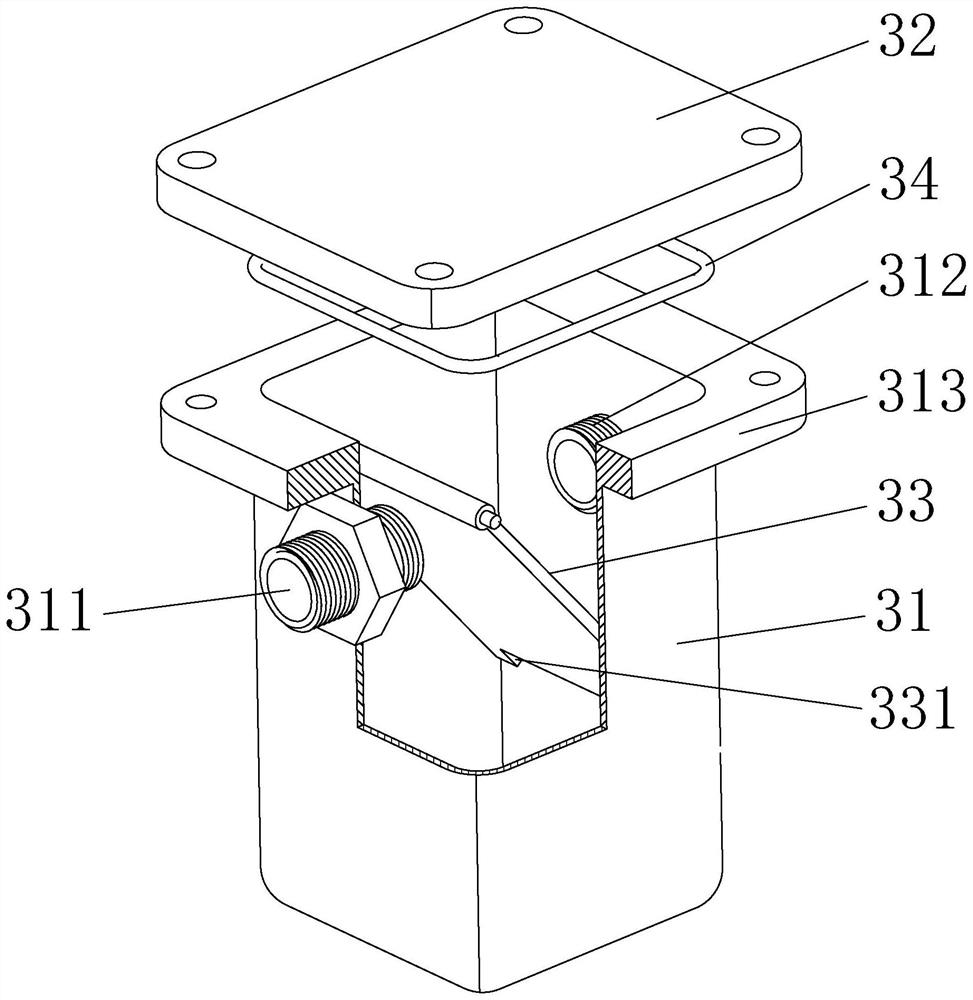

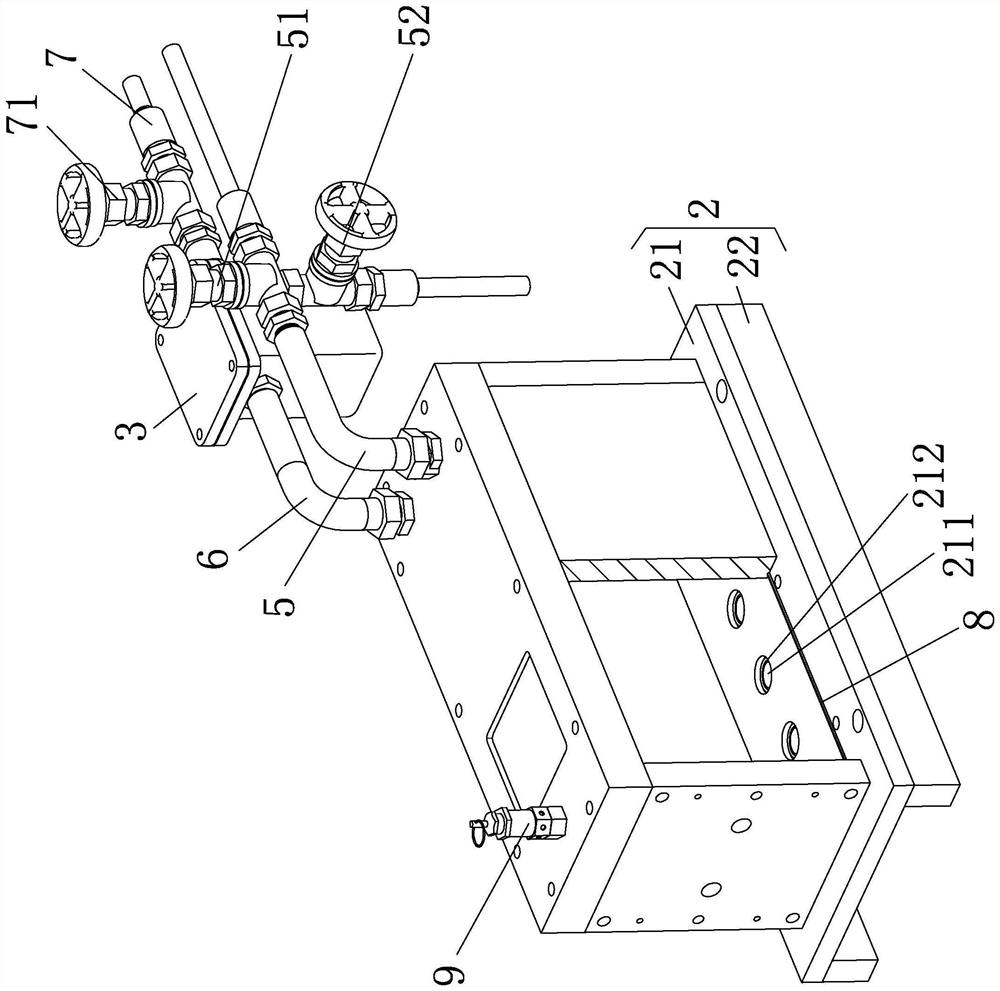

[0021] see figure 1 , The present invention relates to a packaging device for a capacitor without a case, comprising a mold body 1 , a base 2 and a flash collector 3 . The mold main body 1 is supported on the base 2. The mold mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com