Evaporator for hydride vapor phase epitaxial growth of gallium nitride

A hydride gas phase and epitaxial growth technology, which is applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of not being able to withstand high temperature corrosive atmosphere and low volatilization efficiency, and achieve long service life, high volatilization efficiency, Not easy to be corroded by high temperature corrosive atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

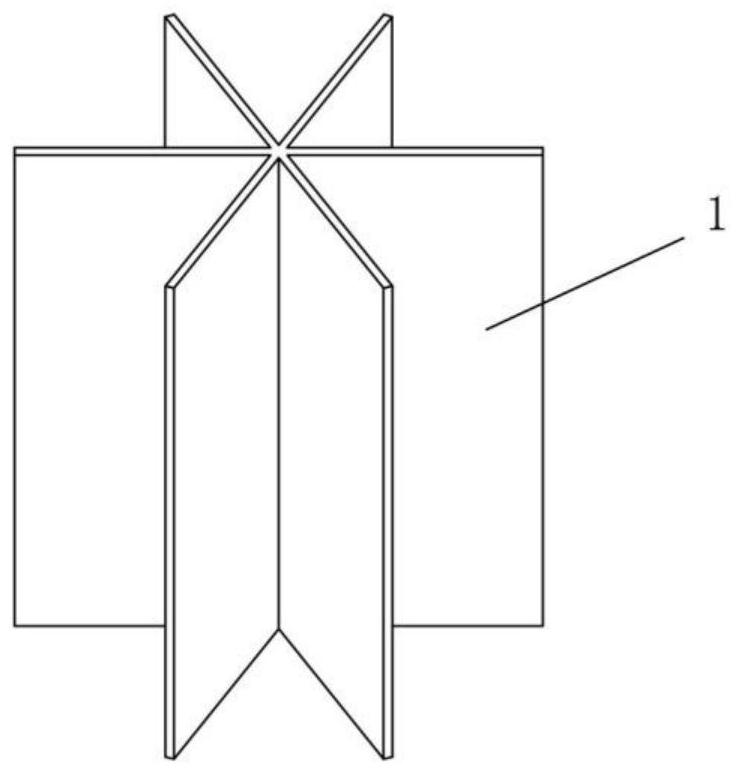

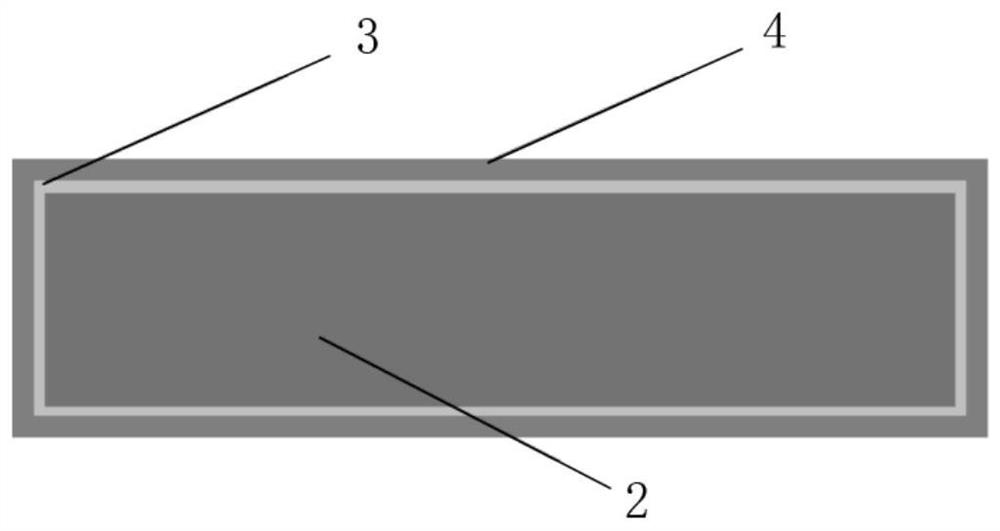

[0024] see figure 1 with figure 2 , an evaporator 1 for hydride vapor phase epitaxial growth of gallium nitride according to an embodiment of the present invention, the evaporator 1 mainly includes a graphite substrate 2, and a silicon transition layer 3 is coated on the outer surface of the graphite substrate 2 , the outer surface of the silicon transition layer 3 is coated with a layer of TaC coating 4; and, the porosity of the TaC coating 4 gradually increases from the side close to the silicon transition layer 3 to the side away from the silicon transition layer 3 ; That is to say, the porosity of the TaC coating 4 gradually increases from the inside to the outside.

[0025] The above-mentioned evaporator 1 is coated with a silicon transition layer 3 on the outer surface of the graphite substrate 2, and the silicon transition layer 3 is used as a sacrificial protective layer to relieve thermal stress; the outer surface of the silicon transition layer 3 is coated with TaC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com