Skin care product for skin whitening and preparation method thereof

A skin care product and whitening technology, applied in the field of skin care products with whitening effect and its preparation, can solve problems such as skin irritation, skin burns, poor stability, etc., achieve the effect of lightening spots, no toxicity, and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

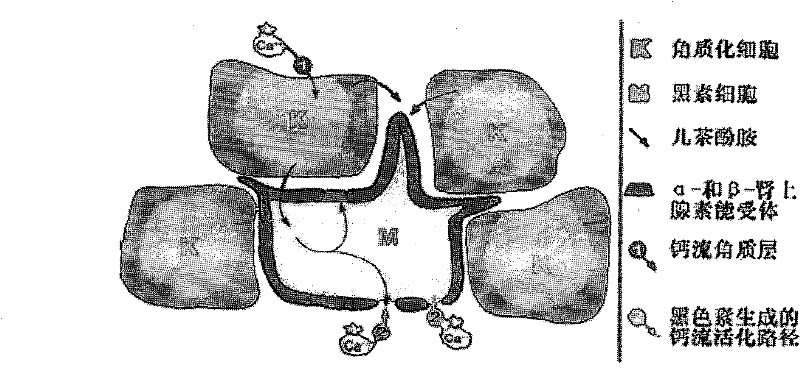

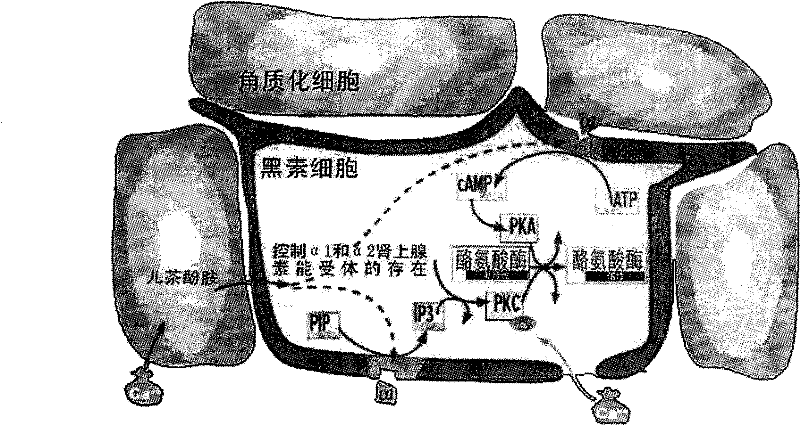

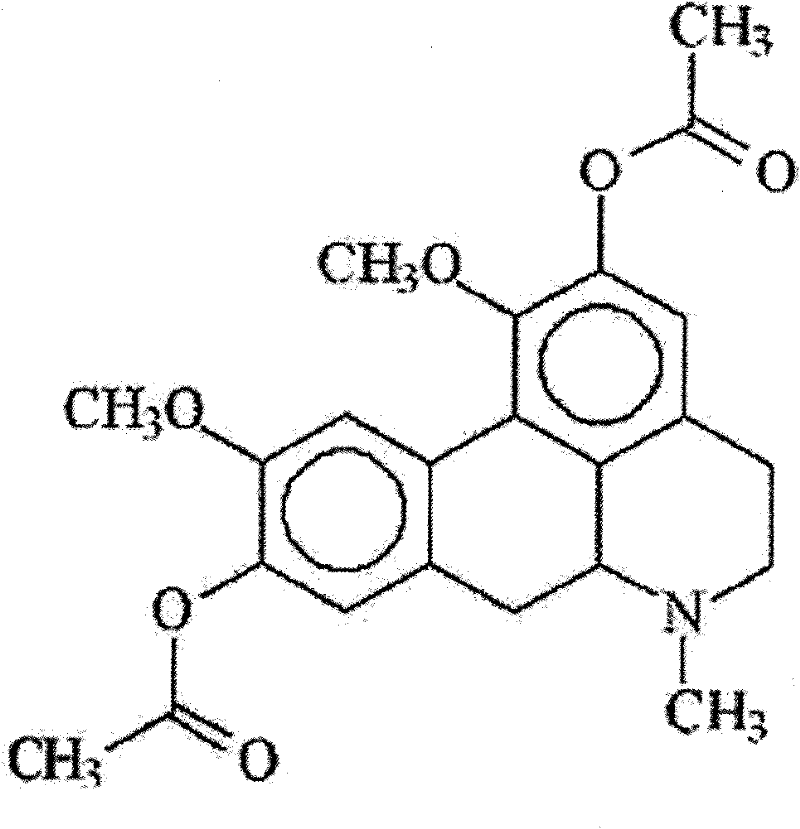

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of whitening lotion or whitening cream is that the oil phase raw materials including emulsifier 3.6%, emollient 16%, diacyl dimethoxy-methyl-noraporphine 0.00004% are put into the oil phase pot, and the The steam inside is heated to 80-90°C; water phase raw materials including skin moisturizer 3.0%, metal alloying agent 0.1%, and reverse osmosis water 76.29996% are put into the water phase pot, and the steam in the jacket is heated to 80-90°C ; Keep the two pots at 80-90°C for 30 minutes, first pump the raw materials in the water pot into the main reaction kettle, pump the oil phase raw materials into the main reaction kettle while starting the high-speed disperser, and continue to open the high-speed disperser 8 Minutes, change to medium-speed stirring, and at the same time, add 0.5% of preservatives and 0.5% of essence into the main reaction kettle when the temperature is lowered to 45°C by cooling water, and discharge when the temperature is lowered to room tem...

Embodiment 2

[0091] A kind of whitening cream is that the oil phase raw materials including emulsifier 4.0%, emollient 15.6%, diacyl dimethoxy-methyl-noraporphine 0.00004% are put into the oil phase pot, and the steam in the jacket Heat to 80-90°C; put the water phase raw materials including 3.7% skin moisturizer, 0.1% metal alloy, and 75.59996% reverse osmosis water into the water phase pot, and heat it to 80-90°C by the steam in the jacket; two pots Keep it at 80-90°C for 30 minutes, first pump the raw materials in the water pot into the main reaction kettle, and pump the oil phase raw materials into the main reaction kettle while starting the high-speed disperser, continue to turn on the high-speed disperser for 8 minutes, change to Stir at a medium speed, and at the same time, when the temperature is lowered from the cooling water to 45°C, add 0.5% of the third-phase preservative and 0.5% of the essence into the main reaction kettle, and discharge when the temperature is lowered to room...

Embodiment 3

[0092] Embodiment 3: a kind of whitening cream is that the oil phase raw material comprises 2% of emulsifier, 20% of emollient, 0.00004% of diacyl dimethoxy-methyl-noraporphine into the oil phase pot. The steam in the jacket is heated to 80-90°C; the water phase raw materials including 4.0% of skin moisturizer, 0.1% of metal alloying agent, and 72.89996% of reverse osmosis water are put into the water phase pot, and heated to 80-90°C by the steam in the jacket. ℃; keep the two pots at 80-90°C for 30 minutes, first pump the raw materials in the water pot into the main reaction kettle, and pump the oil phase raw materials into the main reaction kettle while starting the high-speed disperser, and continue to turn on the high-speed disperser For 8 minutes, change to medium-speed stirring, and at the same time, add 0.5% preservatives and 0.5% essence to the main reaction kettle when the temperature is lowered to 45°C by cooling water, and discharge when the temperature is lowered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com