Method for manufacturing three-hole wire jacket blank

A technology of hole lines and bundles, applied in vehicle parts, railway car body parts, transportation and packaging, etc., can solve the problems of unsatisfactory product comprehensive performance, difficult processing, and lack of quality, and achieve cold extrusion manufacturing. Easy to achieve, fast processing speed, small mold loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

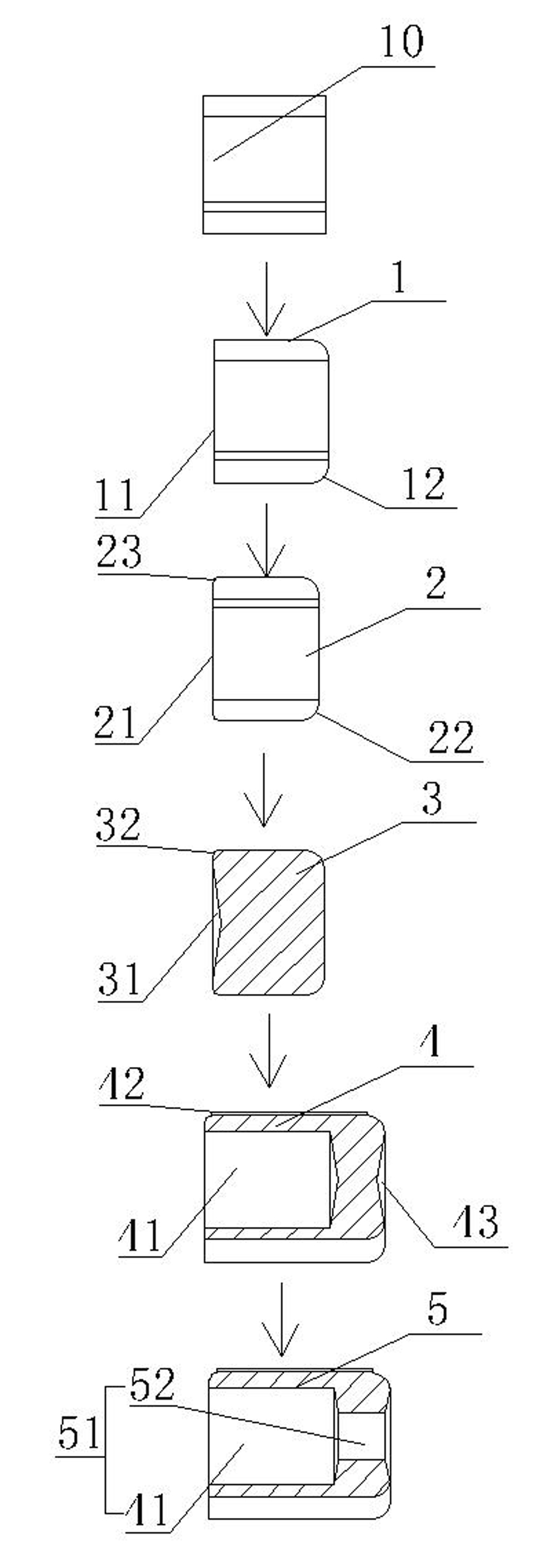

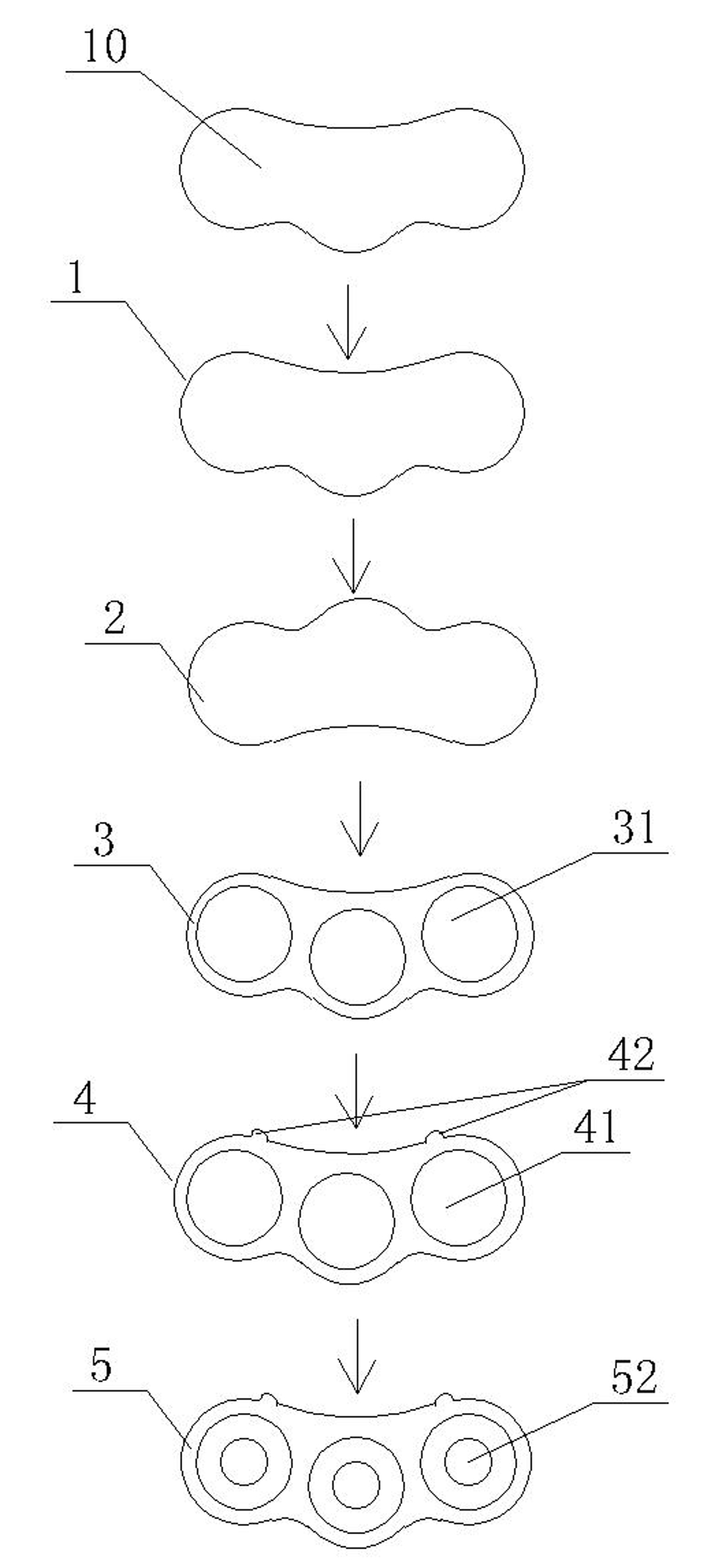

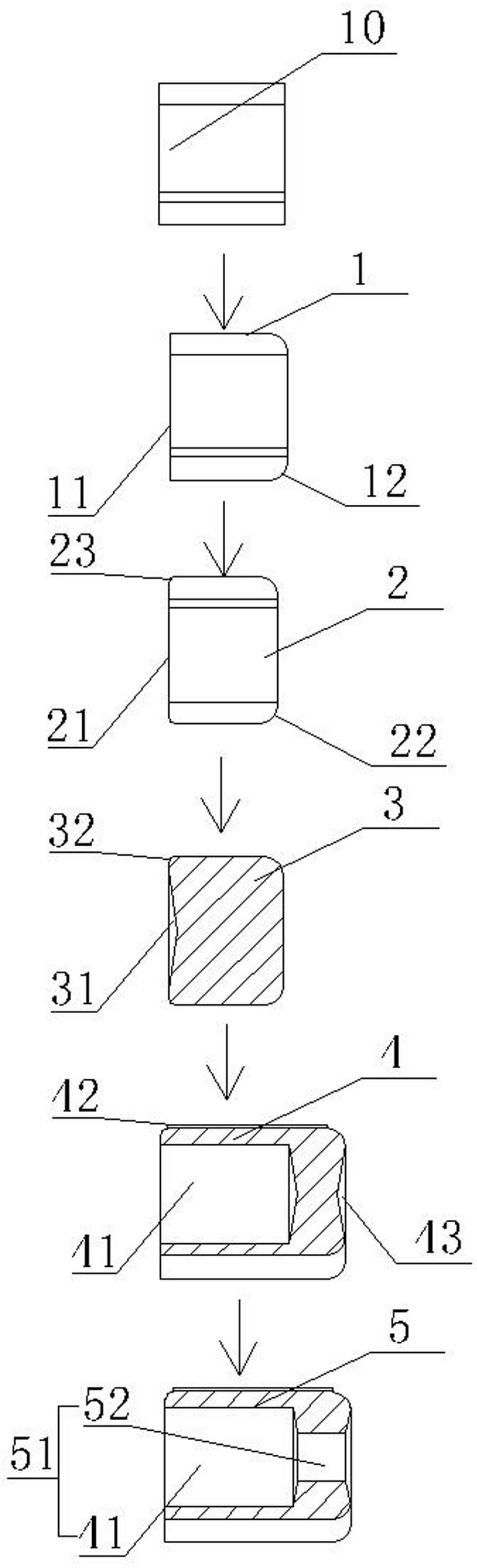

[0017] Refer to attached picture. In the method provided by the present invention, firstly, the billet raw material is subjected to spheroidizing annealing, and then the spheroidizing annealed disc material is rough drawn, and then spheroidized and annealed again, and finely drawn to form a shaped disc whose cross-sectional shape conforms to the three-hole wire harness sleeve. After the material is put into the phosphating pool, the skin is treated with phosphoric acid, and then it is automatically cut into a blank piece 10 of a single three-hole wire harness sleeve in the cold heading machine; Pier handling:

[0018] (1) Use the mechanical fixture to clamp the three-hole wire harness cover blank 10 and send it to the first die opening of the cold extrusion die, and push the three-hole wire harness cover blank into the first die by the punching tool of the first die In the die, there is an ejector rod at the top of the rear end of the die, and the inner wall at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com