Reflection-type LED (light emitting diode) ground row

A reflective, LED light source technology, applied in reflectors, cooling/heating devices of lighting devices, lighting applications, etc., can solve problems such as uneven light, and achieve the effects of large irradiation range, low average temperature, and high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

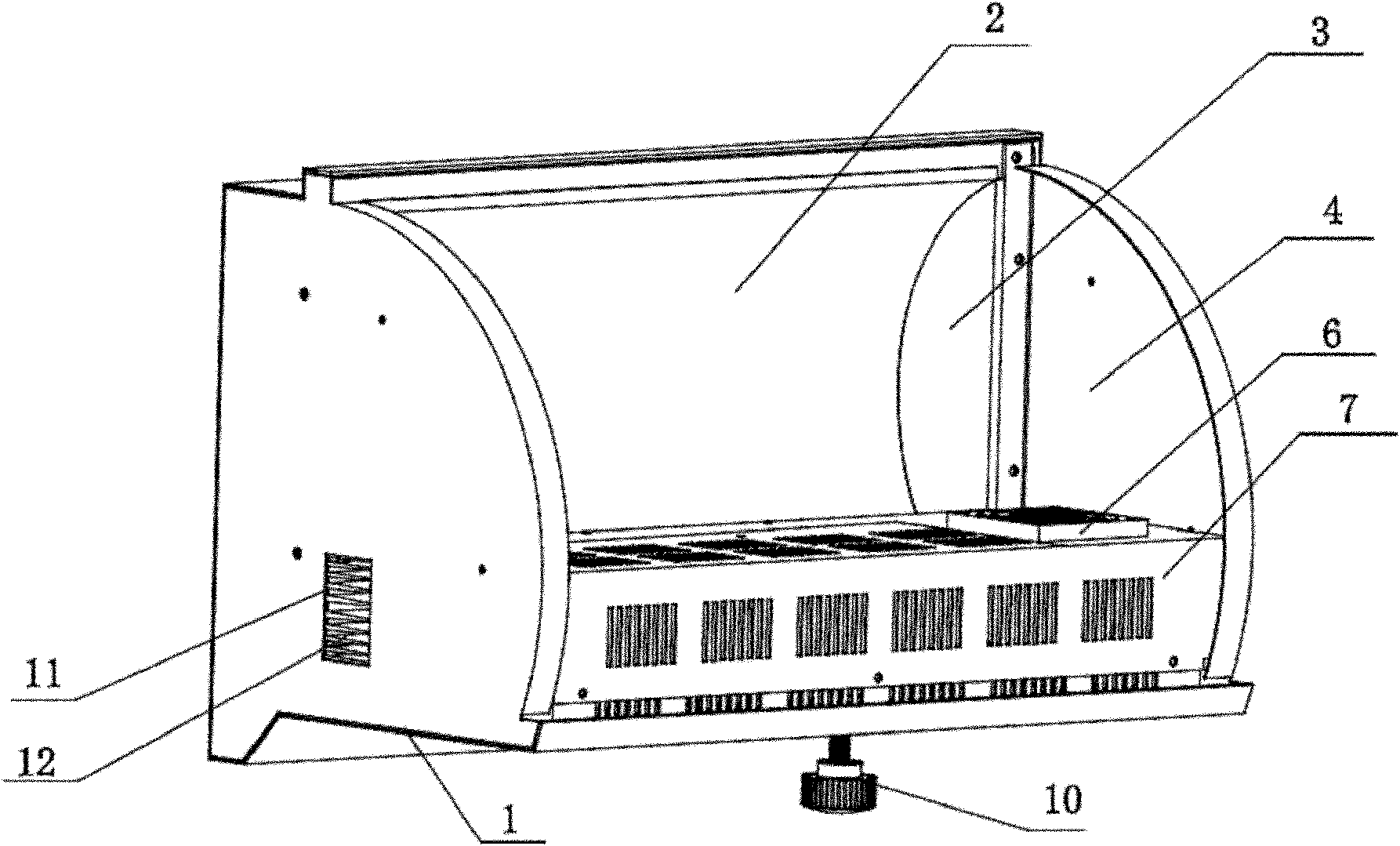

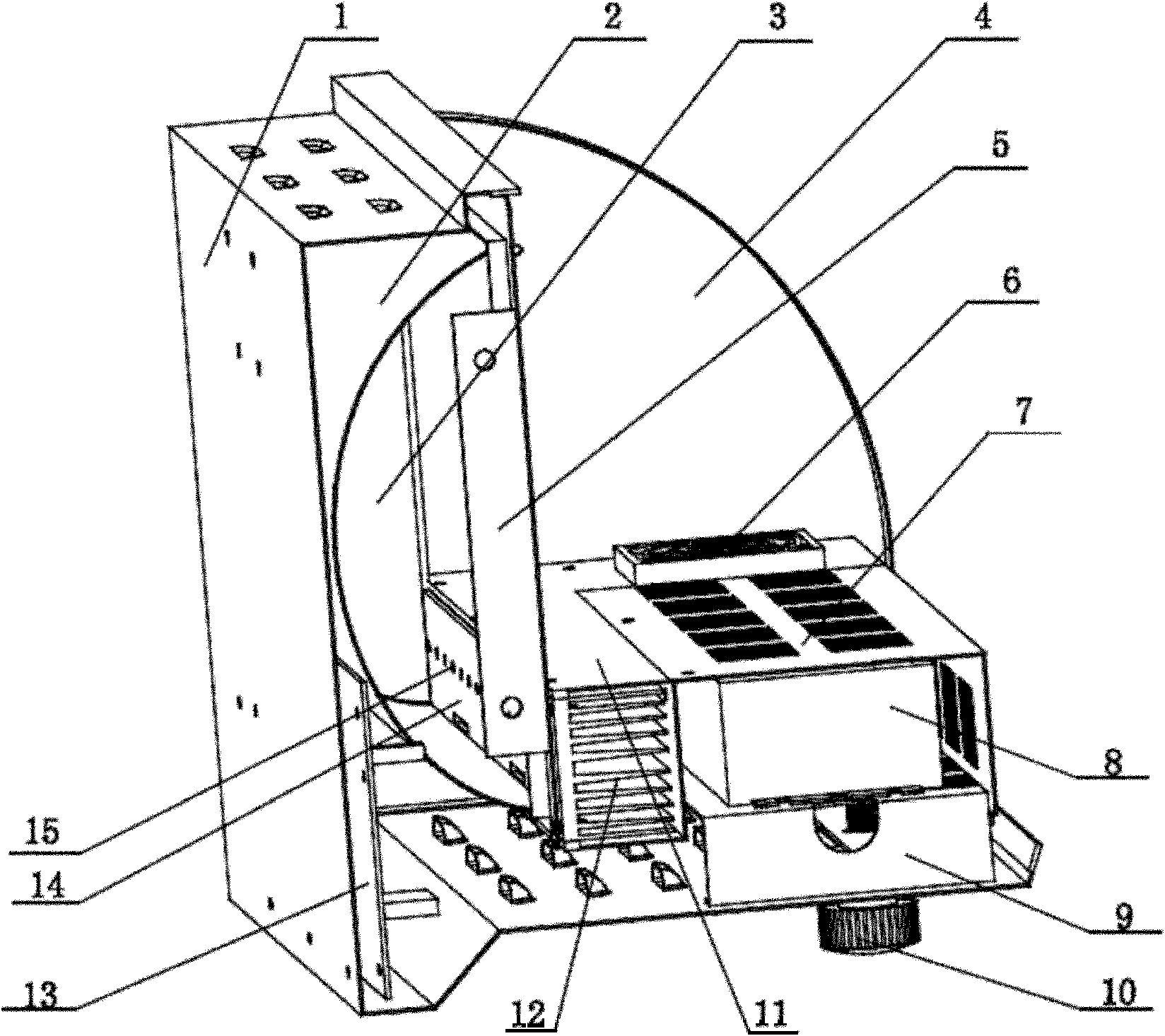

[0021] refer to figure 1 and figure 2 The reflective LED bar lamp includes a lamp body main body 1 , a bracket 5 , a light source part mounted on the bracket, a circuit board 13 electrically connected to the light source part, a heat dissipation part and a power source 8 .

[0022] The main body 1 of the lamp body is a metal frame body, which is a substantially L-shaped plate stamping part. figure 2 As shown in , the L-shaped plate of the main body of the lamp body becomes the back plate and bottom plate of the ground bar lamp. A folded portion parallel to the bottom plate is formed on the top of the back plate. A plurality of cooling holes are stamped on the folded part and the bottom plate respectively.

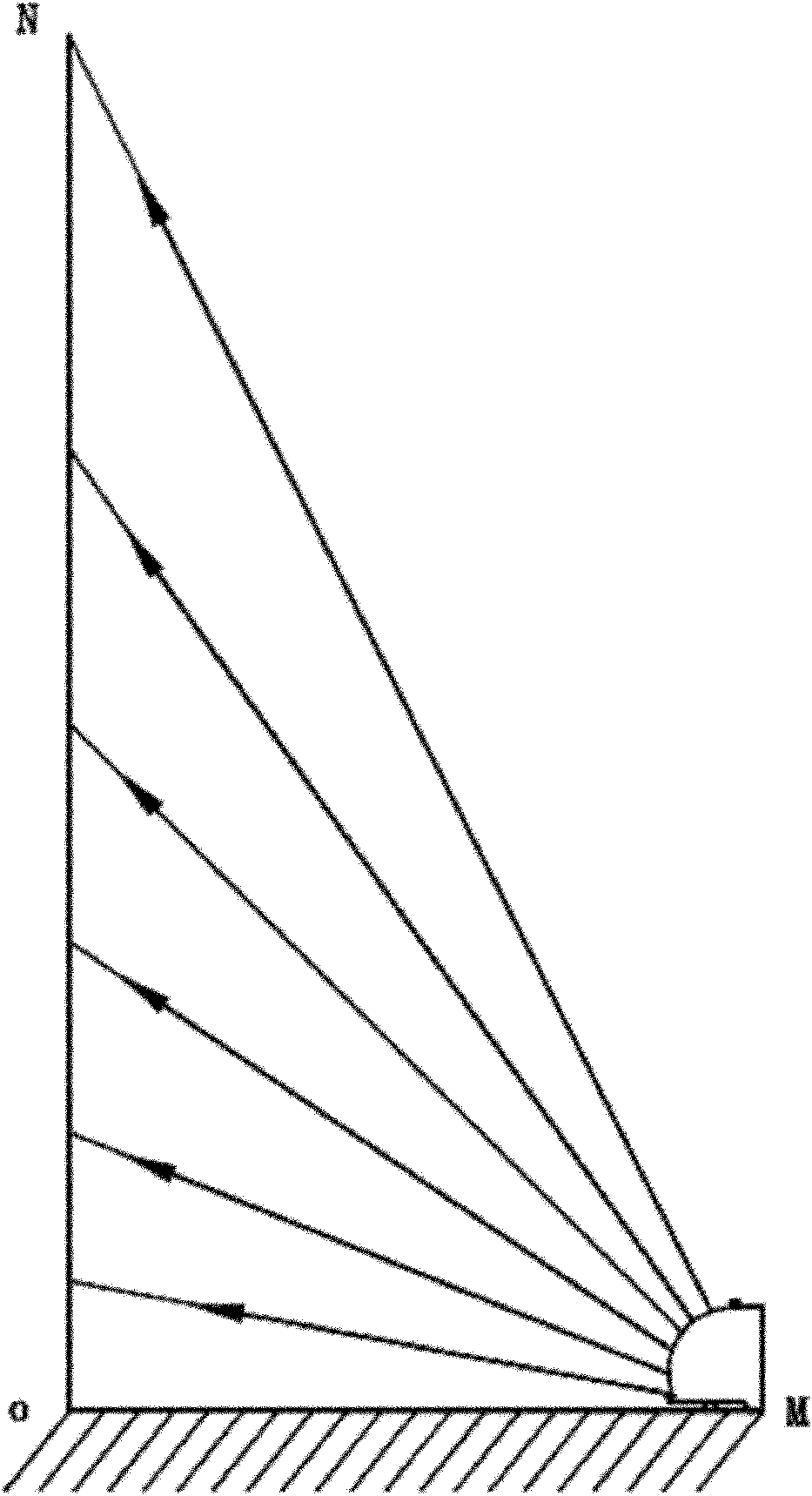

[0023] The light source part specifically includes an LED light source 15 , a substrate 14 , a reflector 2 , and a side reflector 3 . Wherein, the reflector 2 is combined with the reflectors 3 on both sides to form a reflector. The side reflector 3 can be integrally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com