Method for multistage sampling of floating-roof oil tank

A technology of oil storage tanks and floating roofs, which is applied in the direction of sampling devices, etc., to achieve the effect of reducing sampling procedures, reducing labor intensity, and convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

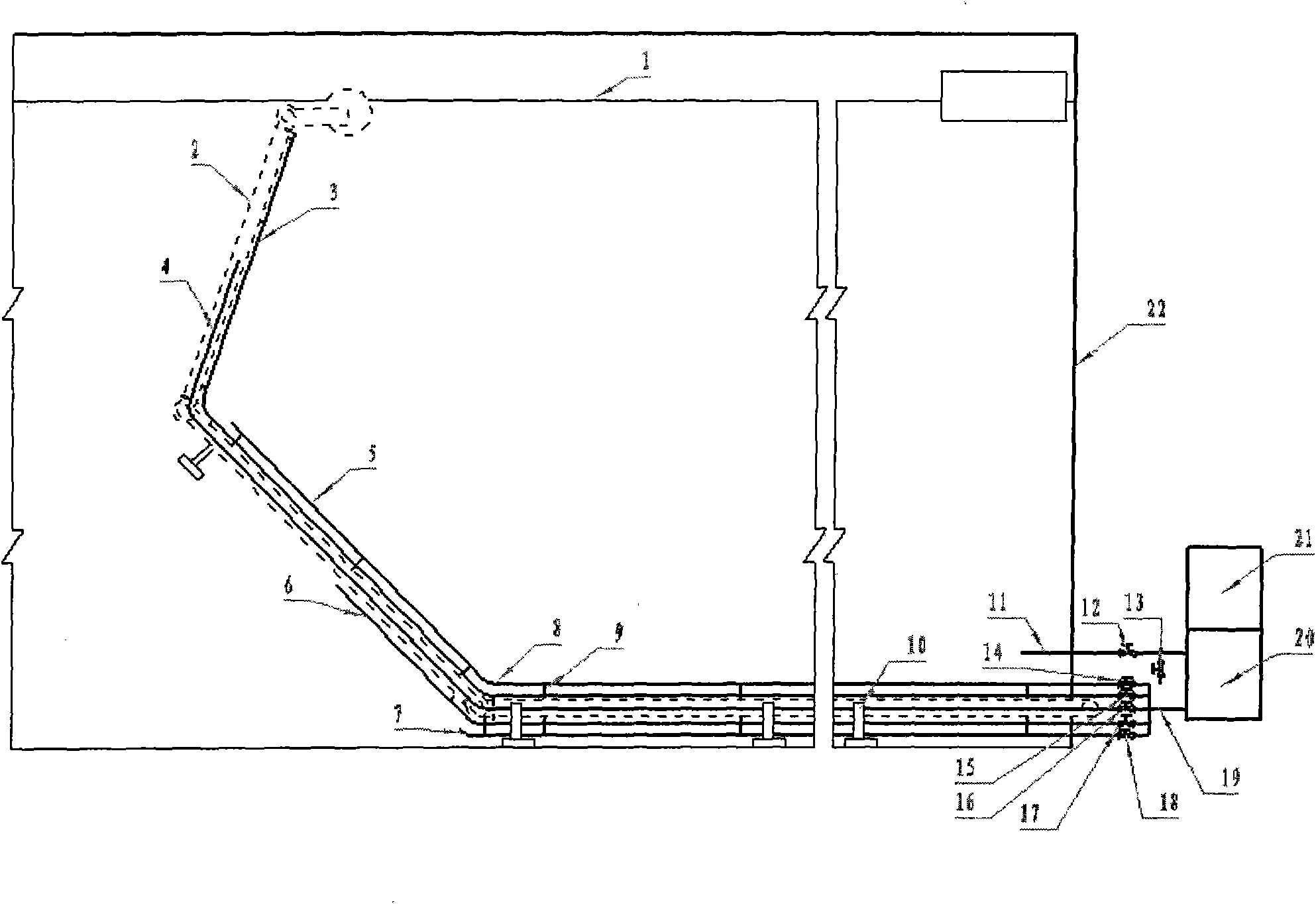

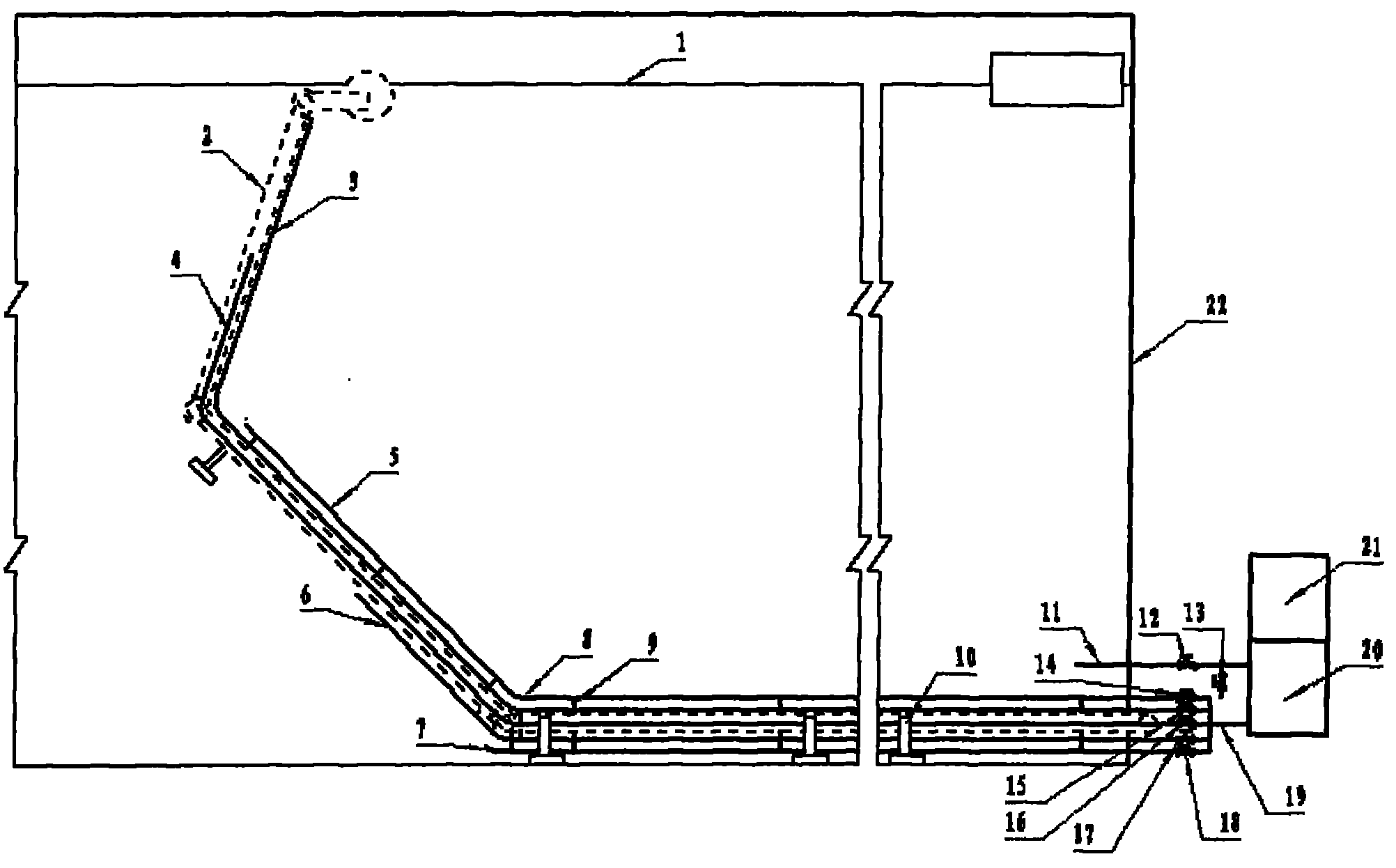

[0013] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0014] Design an upper sampling pipe with a diameter of 15-20mm from the upper part, upper middle part, middle part, middle lower part and lower part of the central drainage pipe 2 of the floating roof oil storage tank to the lower side of the same side of the floating roof oil storage tank 1 3. The upper and middle sampling tube 4, the middle sampling tube 5, the middle and lower sampling tube 6 and the lower sampling tube 7, connect the ends of the above sampling tubes 3, 4, 5, 6, and 7 in parallel with the ycd0.6-0.6 The gear pump inlet pipes of the gear pump 20 are connected, and a sampling control valve 14, 15, 16, 17, 18 is respectively designed on the pipeline before parallel connection; 22, the lower part is connected, and the gear pump outlet control valve 12 and sampling valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com