Aerial plug

A technology for aviation plugs and pins, which is applied to contact parts, devices for joining/disconnecting parts, clamping/spring connections, etc., can solve problems such as desoldering, inconvenient operation, and numerous processes, and achieve reduced labor intensity. The effect of reduced requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

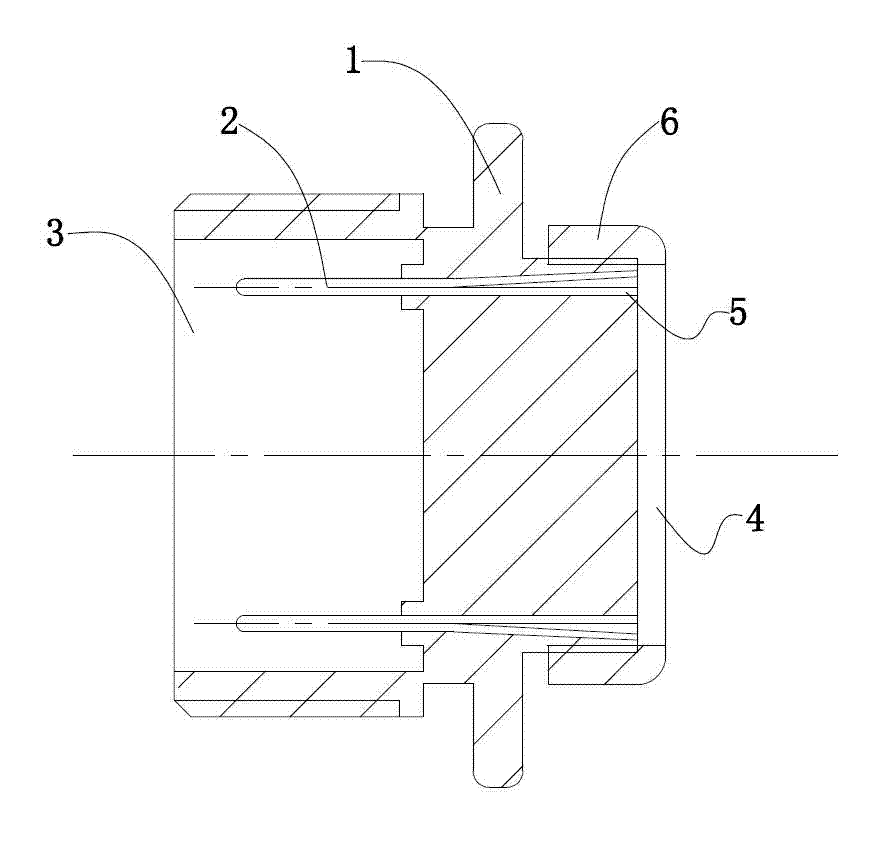

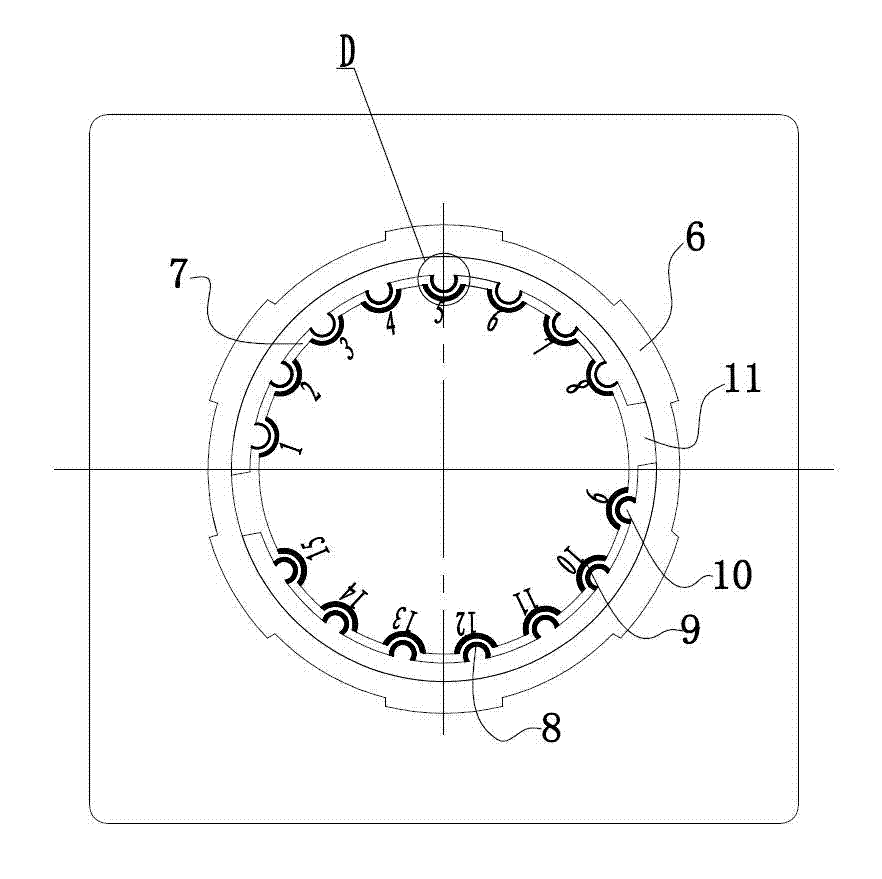

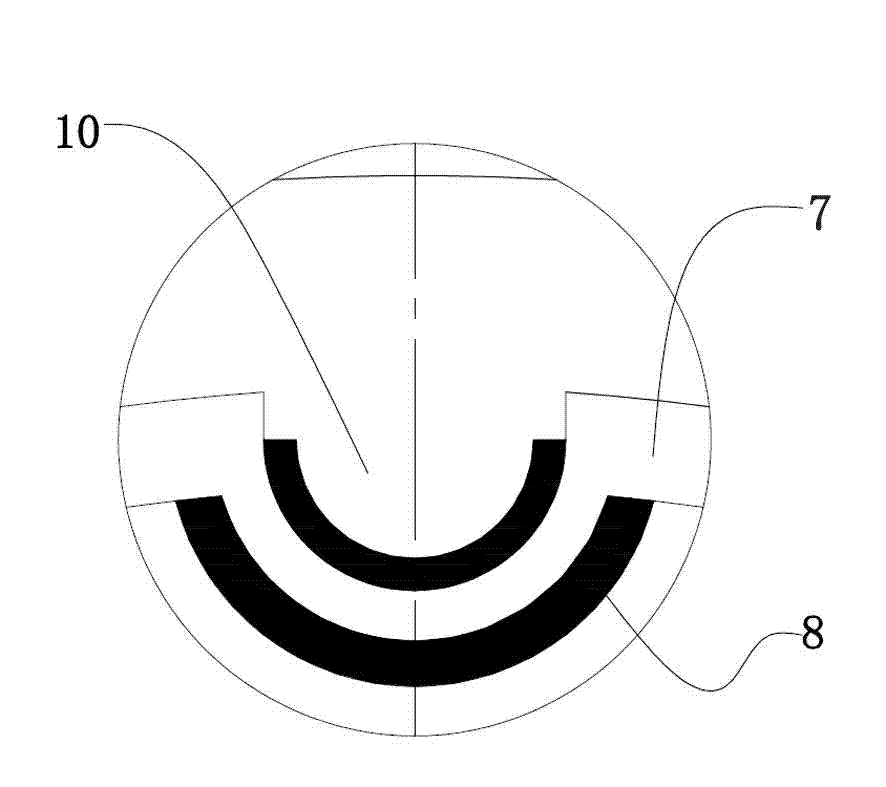

[0021] Embodiment: a kind of aviation plug (see attached figure 1 attached figure 2 ), including an insulated body 1 and a metal pin 2 disposed inside the body, the metal pin 2 and the body 1 are cast into one body, the body 1 is provided with a square flange, and one end of the body 1 is a circular cavity 3 , the other end of the body is a circular solid structure, the solid part is an insulator, the solid end is provided with a ring groove 7, the inner surface of the outer wall of the ring groove is a tapered surface, and two gaps 11 are provided on the outer wall of the ring groove. The inner surface of the outer wall of the groove is provided with semicircular protrusions 10 (see attached image 3 ), the distance between the protrusions is equal, the position of the corresponding protrusion on the outer surface of the inner wall of the ring groove is provided with a semicircular depression 9 matching the protrusion, and the two gaps are symmetrically spaced at 180°. On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com