Method for making ceramic article

A technology of ceramics and ceramic bodies, which is applied in the field of ceramic manufacturing, can solve problems such as excessive batch material mixing, shearing and extrusion pressure, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

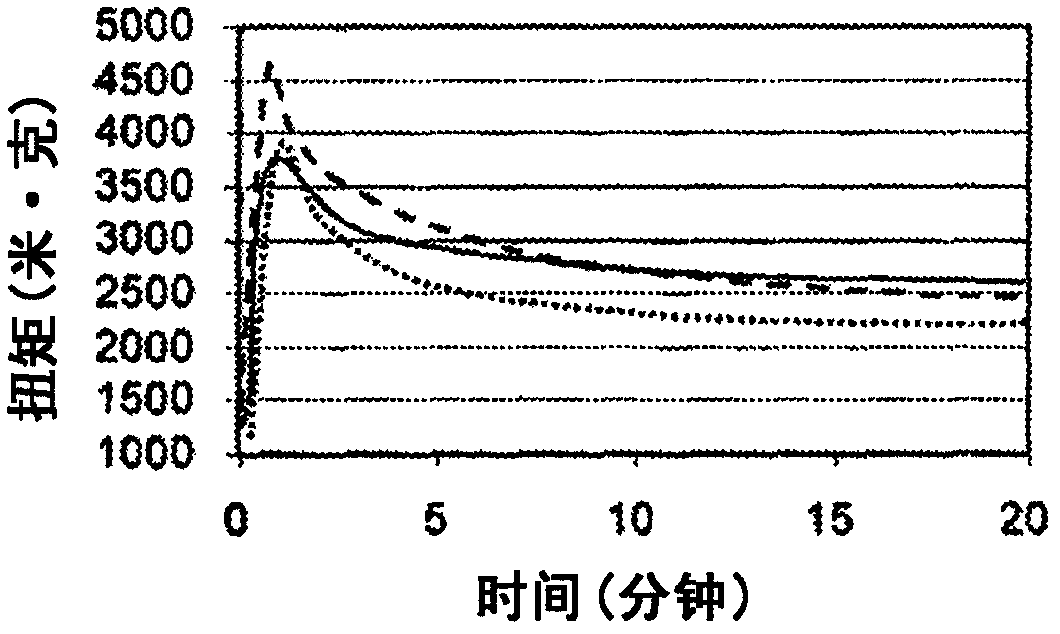

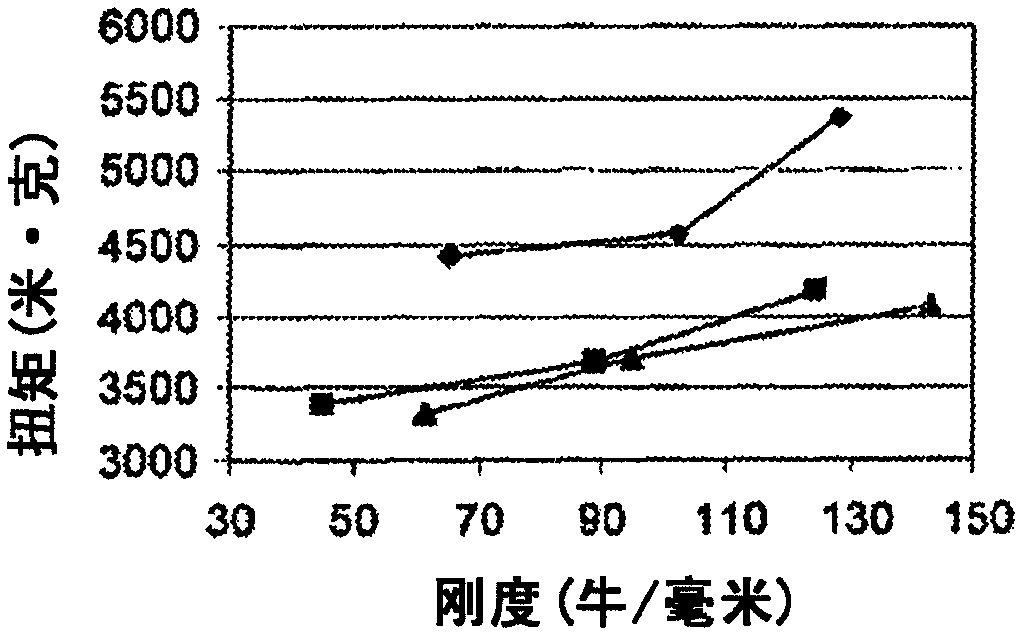

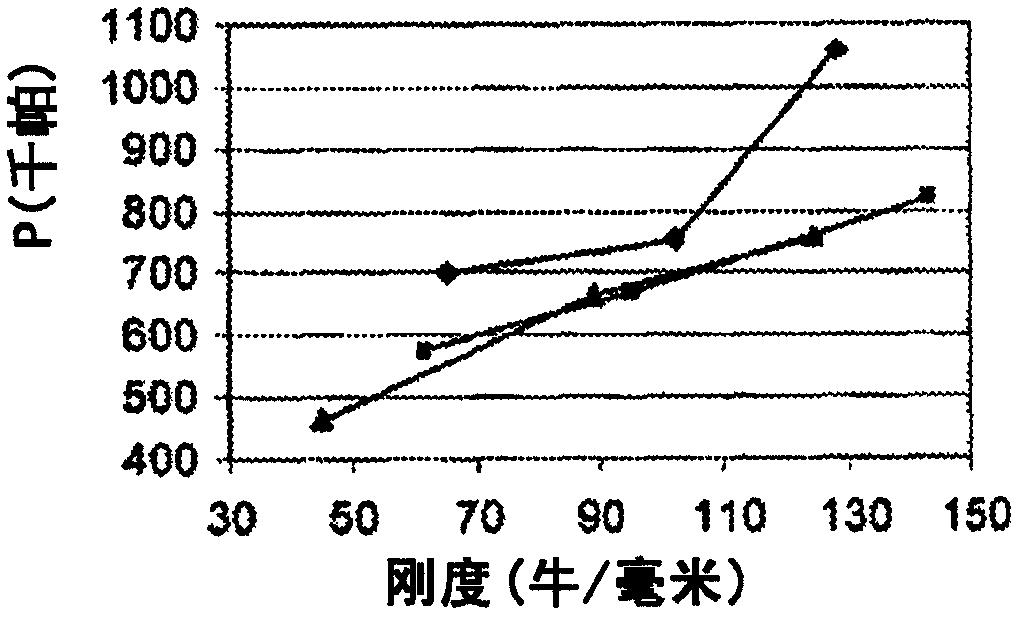

[0035] 1. Paste mixing and rheology testing

[0036] A bulk ceramic powder batch material suitable for extruding ceramic bodies such as ceramic honeycombs is compounded from a blend of the following components: ceramic powder, methylcellulose binder, water, and An optional porogen for the porosity of the ceramic material. Selected batches contain high molecular weight polymeric dispersants to improve the mixing properties of the batch. Table 1 below lists the approximate composition of the batch except for the water (medium) in the batch, wherein all proportions of components are in parts by weight. All dry components, including inorganic oxides and salts as well as graphite, starch and cellulose binders, are weighed as fine powders.

[0037] Table 1. Plasticized Ceramic Paste Compositions

[0038]

[0039] * Dispersant 1 = Solsperse 40000 - a proprietary commercially available anionic phosphated alkoxylated polymer;

[0040] Noveon Inc., Cleveland, OH, USA; molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com