Pre-installation assembly for a contact arrangement of a sensor assembly

一种传感器组件、接触结构的技术,应用在仪器、连接、制动器等方向,能够解决影响结构空间特性、卷绕端部接触面大等问题,达到有利安装特性、方便定位和保持的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

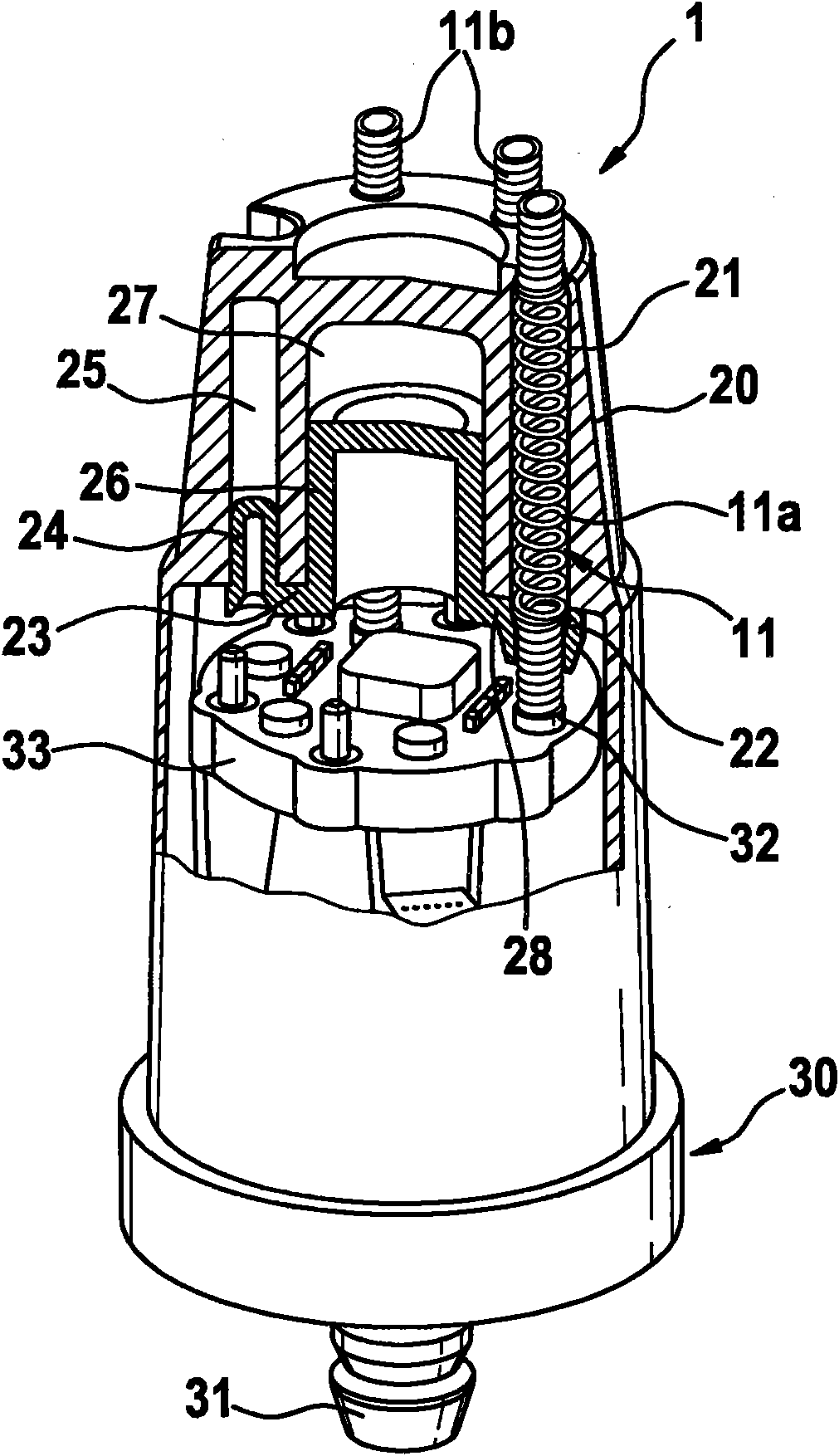

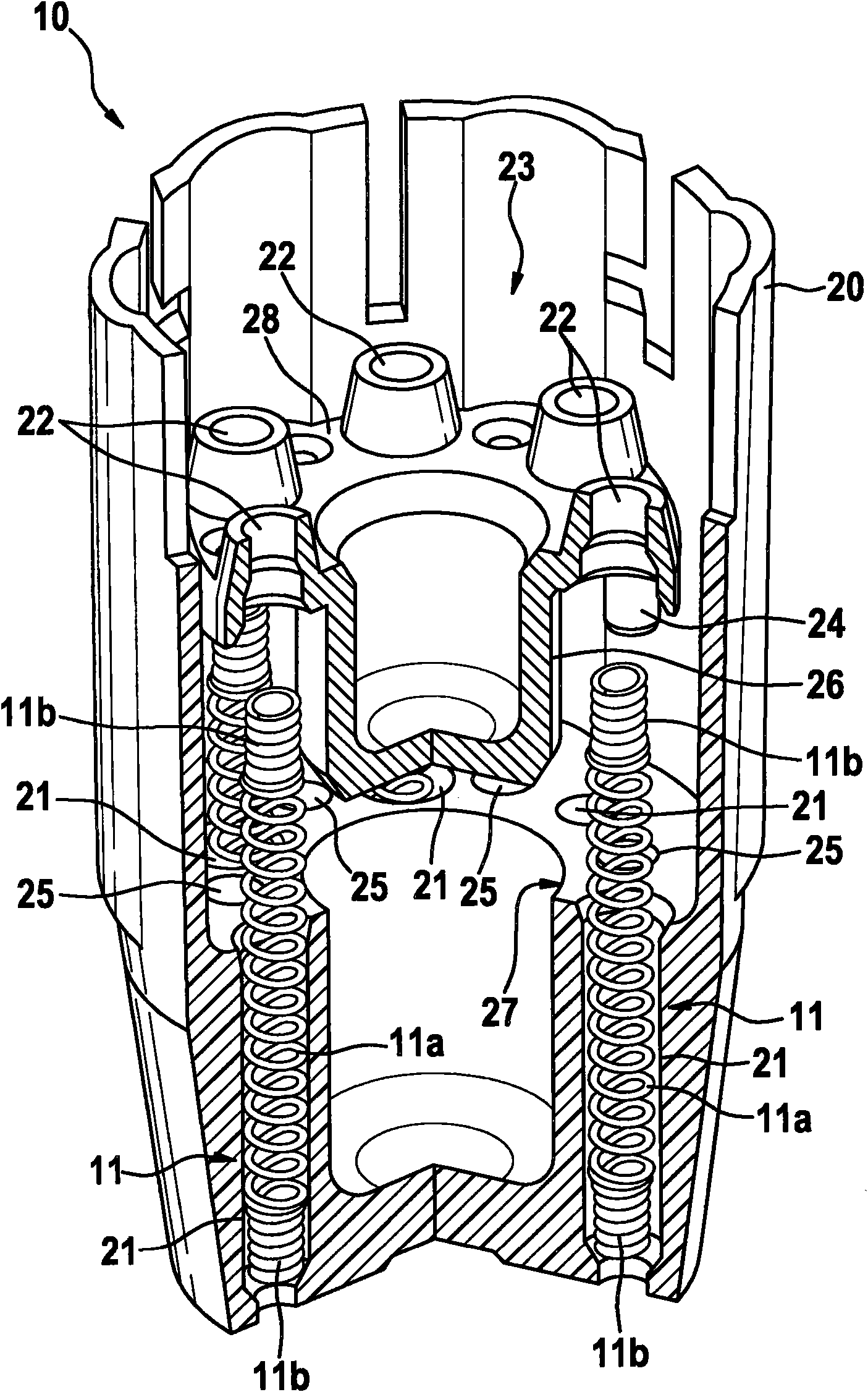

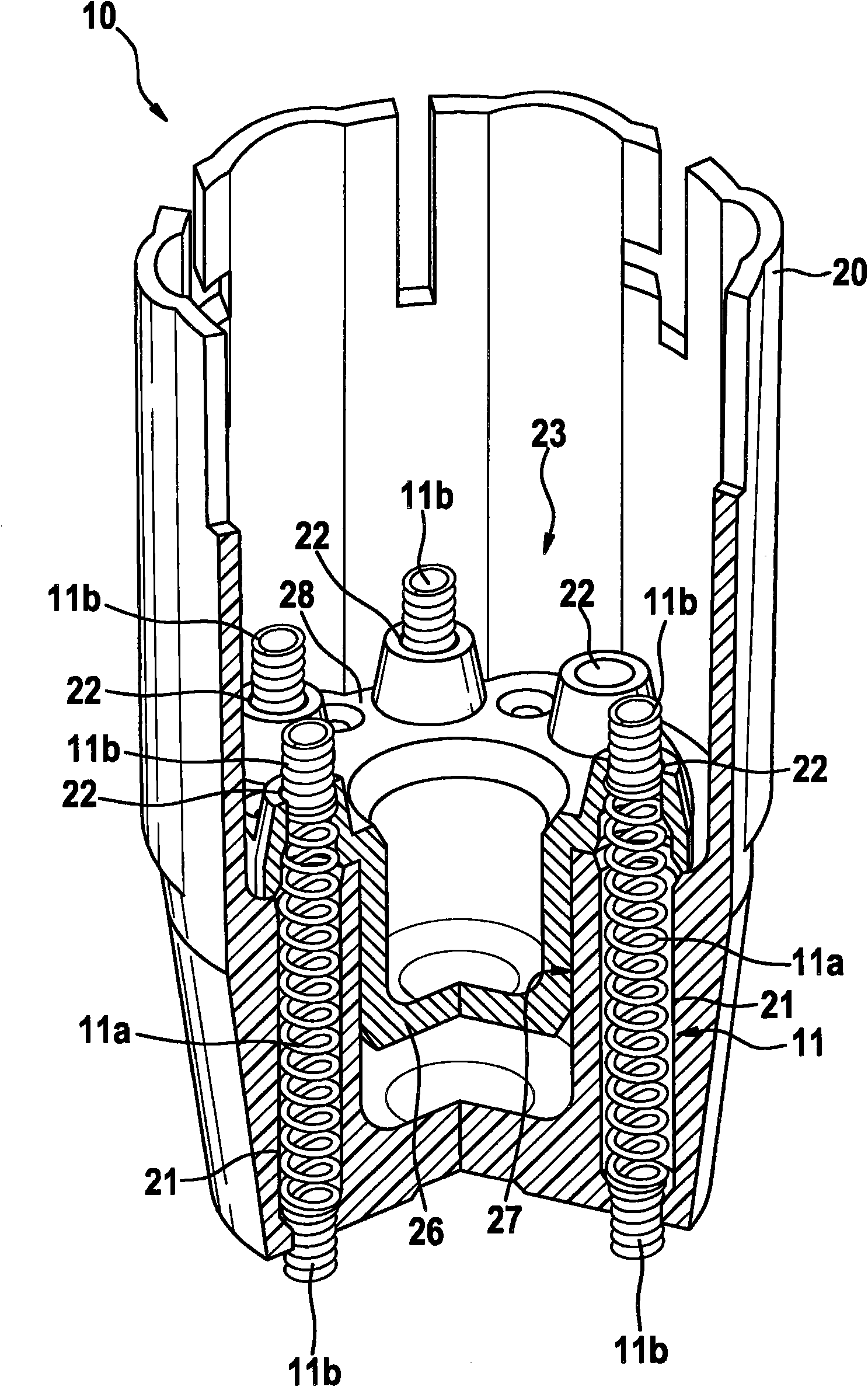

[0019] figure 1 The contact arrangement 1 shown comprises a total of four spring contact pins 11, which are arranged in a frustoconical housing cover 20 made of insulating plastic and serve to unblock the braking device of the motor vehicle braking system. The attached control device shown is electrically connected to a pressure sensor of the sensor unit 30 for measuring the brake pressure. Since the housing cover 20 and the sensor unit 30 are shown cut away on the circumferential side, the figure 1Only three of the four spring contact pins 11 in total can be seen. From the center of the underside of the sensor unit 30 , a pipe connection 31 projects which, in the installed state, engages in a sealed condition in a corresponding bore of a hydraulic manifold (not shown) and thus establishes a connection between the pressure sensor and the corresponding braking device. Fluid connections for hydraulic systems. Thus, in the assembled brake device, the contact structure 1 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com