Sleeve machining center frame with dual regulating functions

A processing center and double adjustment technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of slow speed, low casing processing efficiency, cumbersome adjustment, etc., to achieve repeated adjustment, fast adjustment, Reduce the effect of the control link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

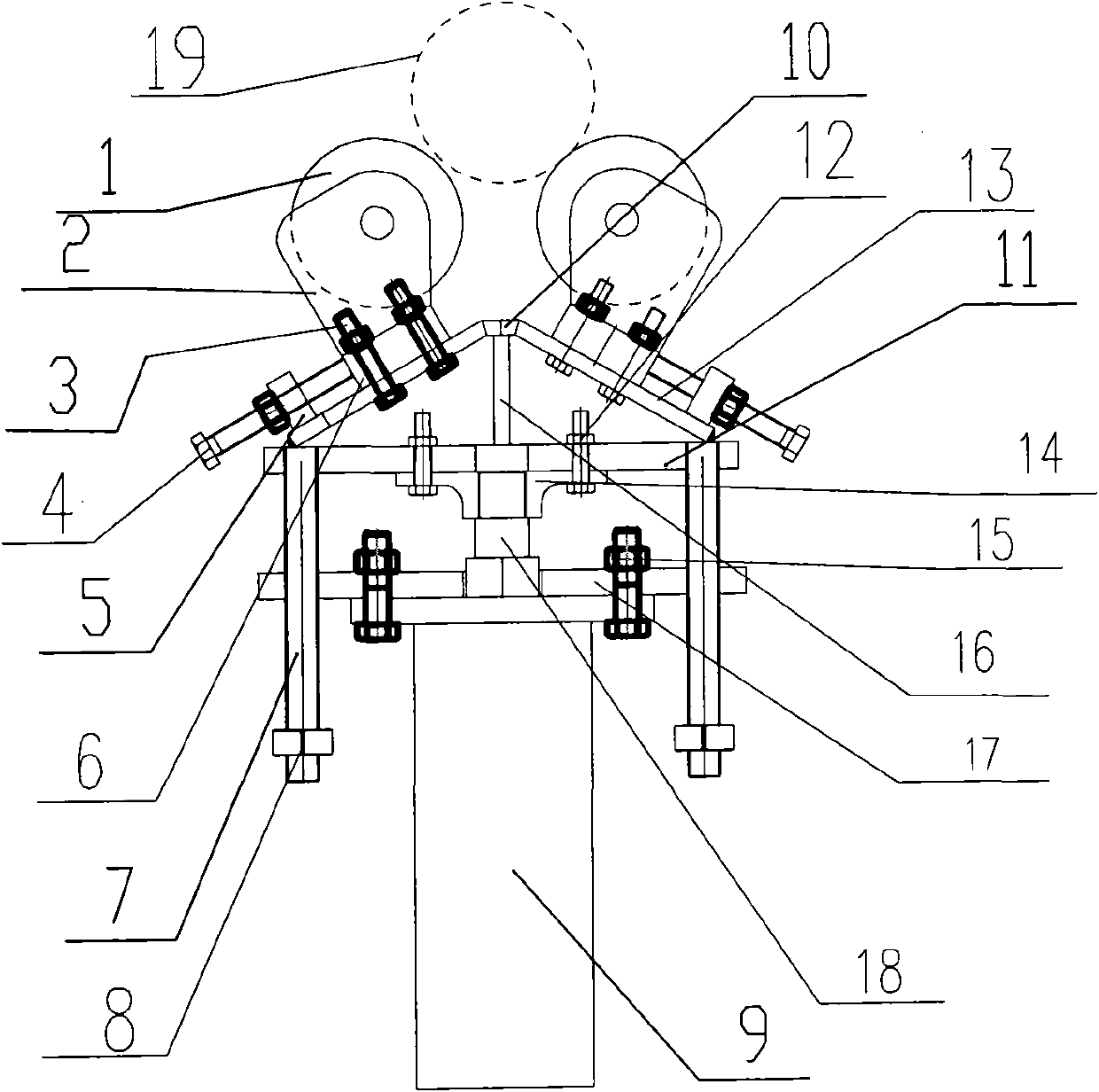

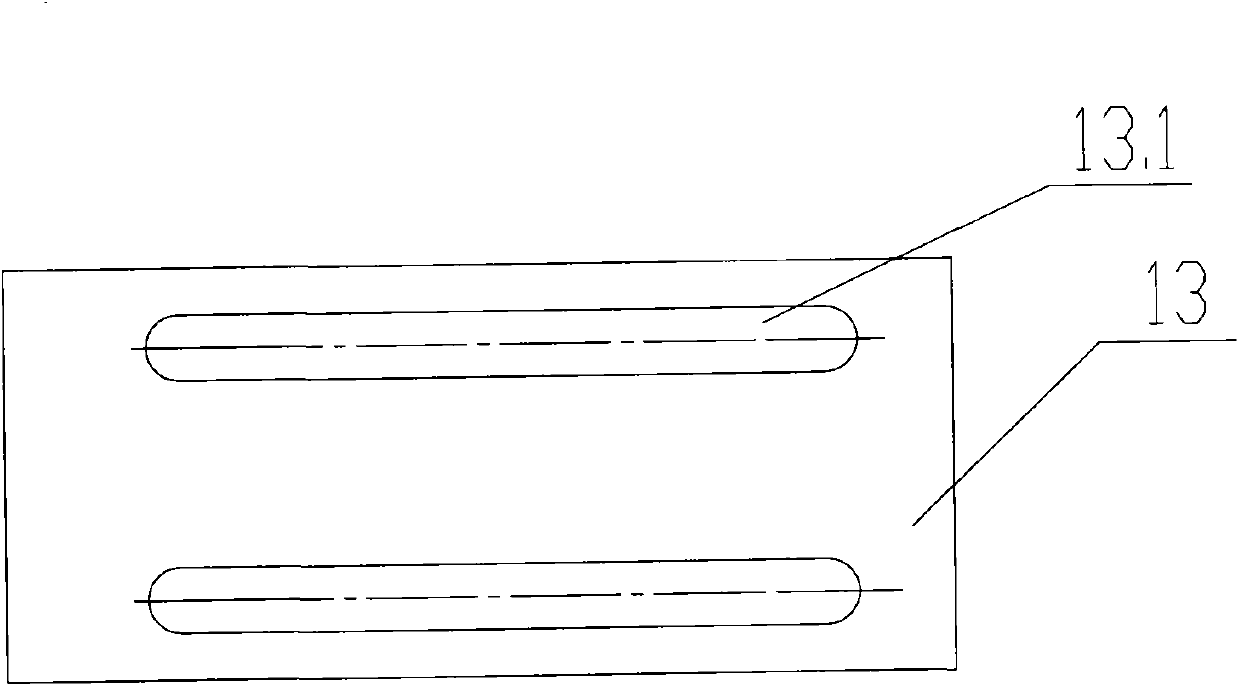

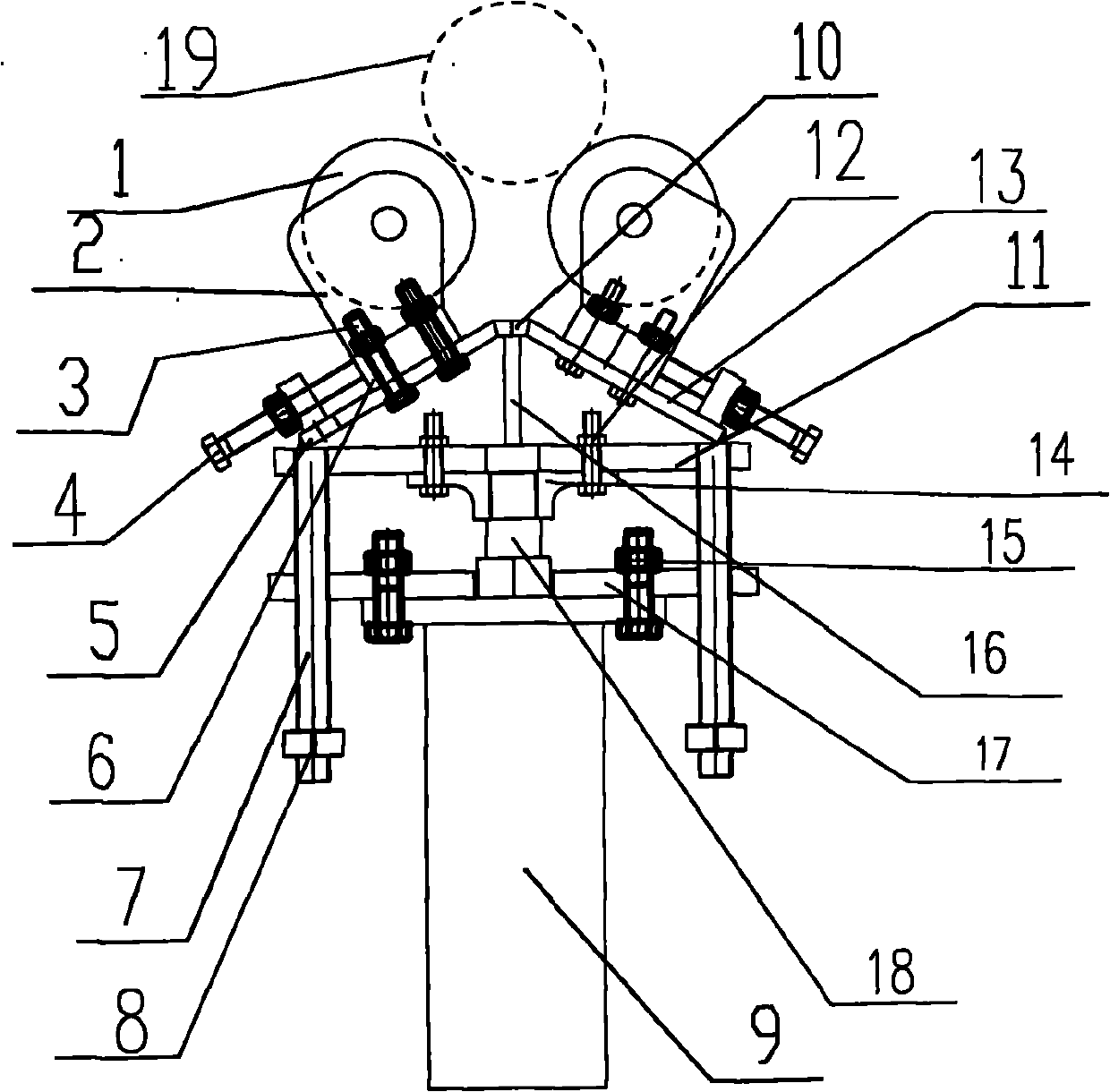

[0019] see figure 1 , a casing processing center frame with dual adjustment functions, including a support plate 11 and two top wheels 1 oppositely arranged, the two top wheels 1 are installed on the shaft between two corresponding splints 2, the top wheels 1 can Rotate on the shaft, clamping plate 2 is connected on the slide block 6 by bolt 3, is provided with two swash plates 13 oppositely on the support plate 11, slide block 6 is arranged on the swash plate 13, slide block 6 can be on the swash plate 13 move back and forth radially, see figure 2 The slant plate 13 is provided with two parallel through grooves 13.1 along the length direction of the slant plate 13, and a splint 2 is arranged on one through groove 13.1, and the bolt 3 passes through the through groove 13.1 to connect the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com