Cabin cleaning robot

A technology for cleaning robots and ship cabins. It is applied to cleaning equipment for ship tanks, oil tankers, motor vehicles, etc. It can solve problems such as poisoning accidents, high labor intensity of workers, and serious health hazards for workers, and achieve reliable work and solve labor problems. The effect of high work intensity and high risk of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

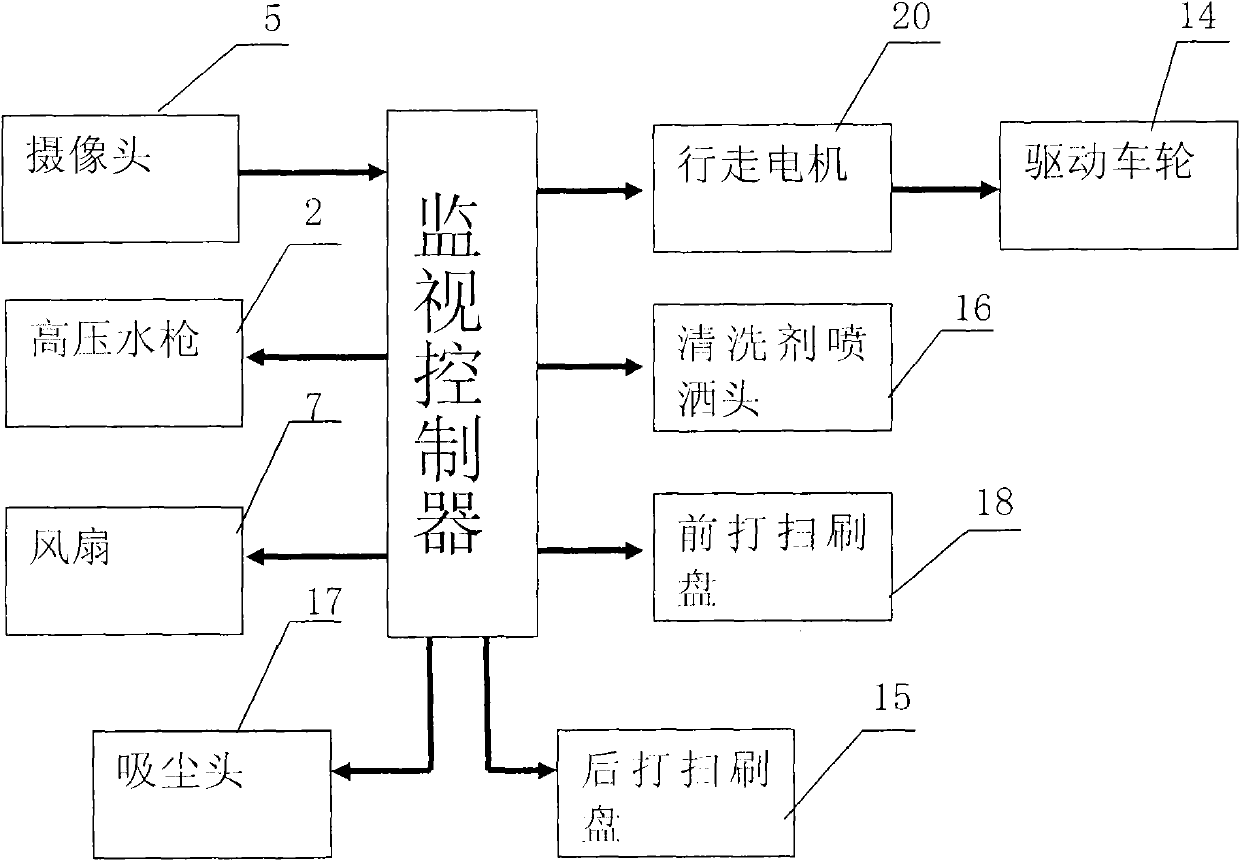

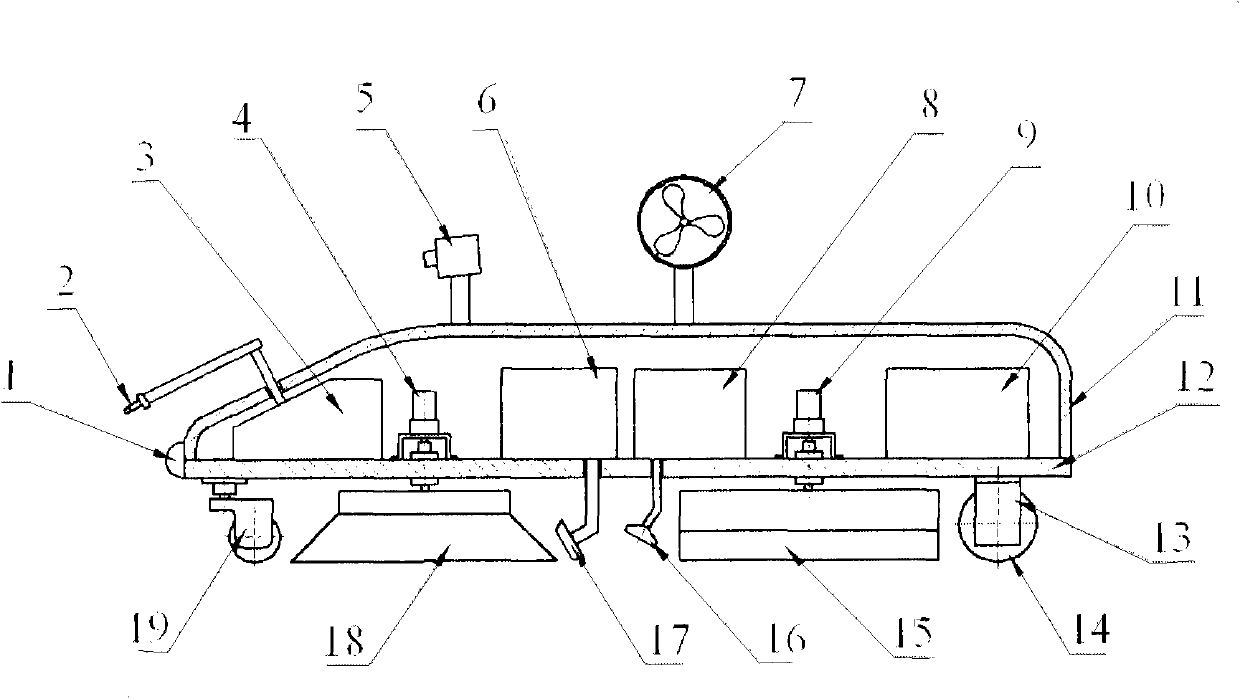

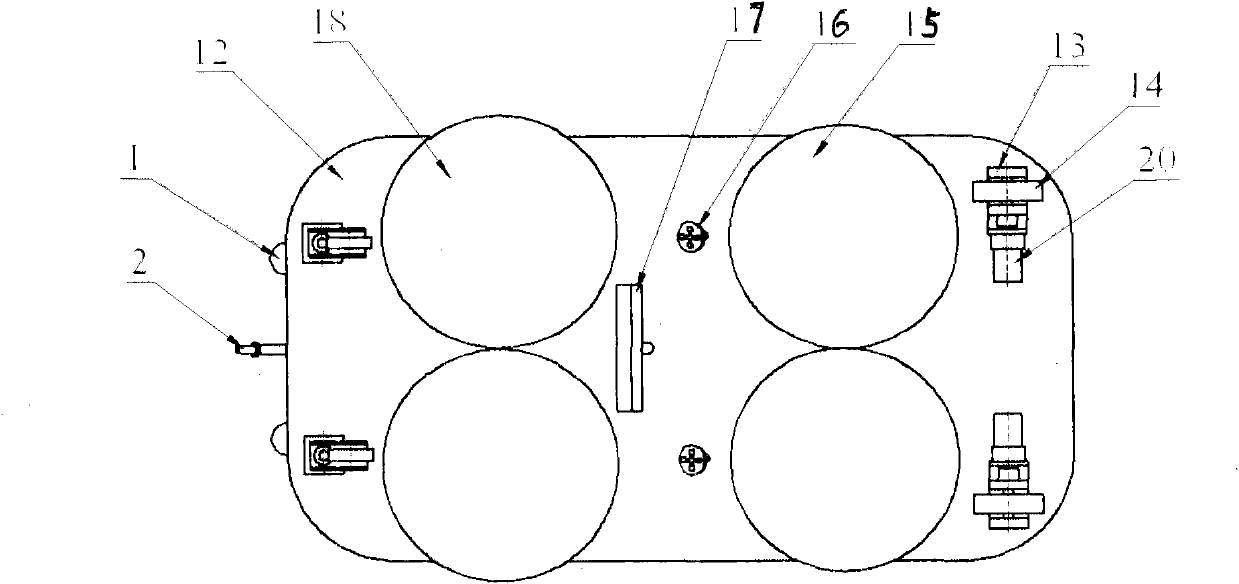

[0011] As shown in the figure, the cabin cleaning robot of the present invention includes a lighting lamp 1, a high-pressure water gun 2, a water tank 3, a front brush motor 4, a camera 5, a garbage temporary storage bin 6, a fan 7, a cleaning agent storage bin 8, and a rear brush disc Motor 9, control box 10, shell 11, chassis 12, wheel frame 13, driving wheel 14, rear cleaning brush plate 15, cleaning agent spray head 16, vacuum head 17, front cleaning brush plate 18, universal wheel 19, walking Motor 20, before the robot is used, water tank 3 is filled with water, cleaning agent storage bin 8 is filled with cleaning agent, and garbage temporary storage bin 6 is emptied, and the operator makes a cleaning plan according to the cabin situation to be cleaned. Under the control of the operator located in the central control room, the robot enters the cabin, first starts the fan 7, ventilates the cabin, and eliminates the toxic gas that may exist inside the cabin; Clean the brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com