Hydraulic clamp capable of tilting vertical and horizontal rolls in air

A clamp and hydraulic technology, which is applied in the field of steel coil hoisting and flipping equipment, can solve the problems of increasing production costs, and achieve the effects of saving production costs, convenient control, and avoiding stalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

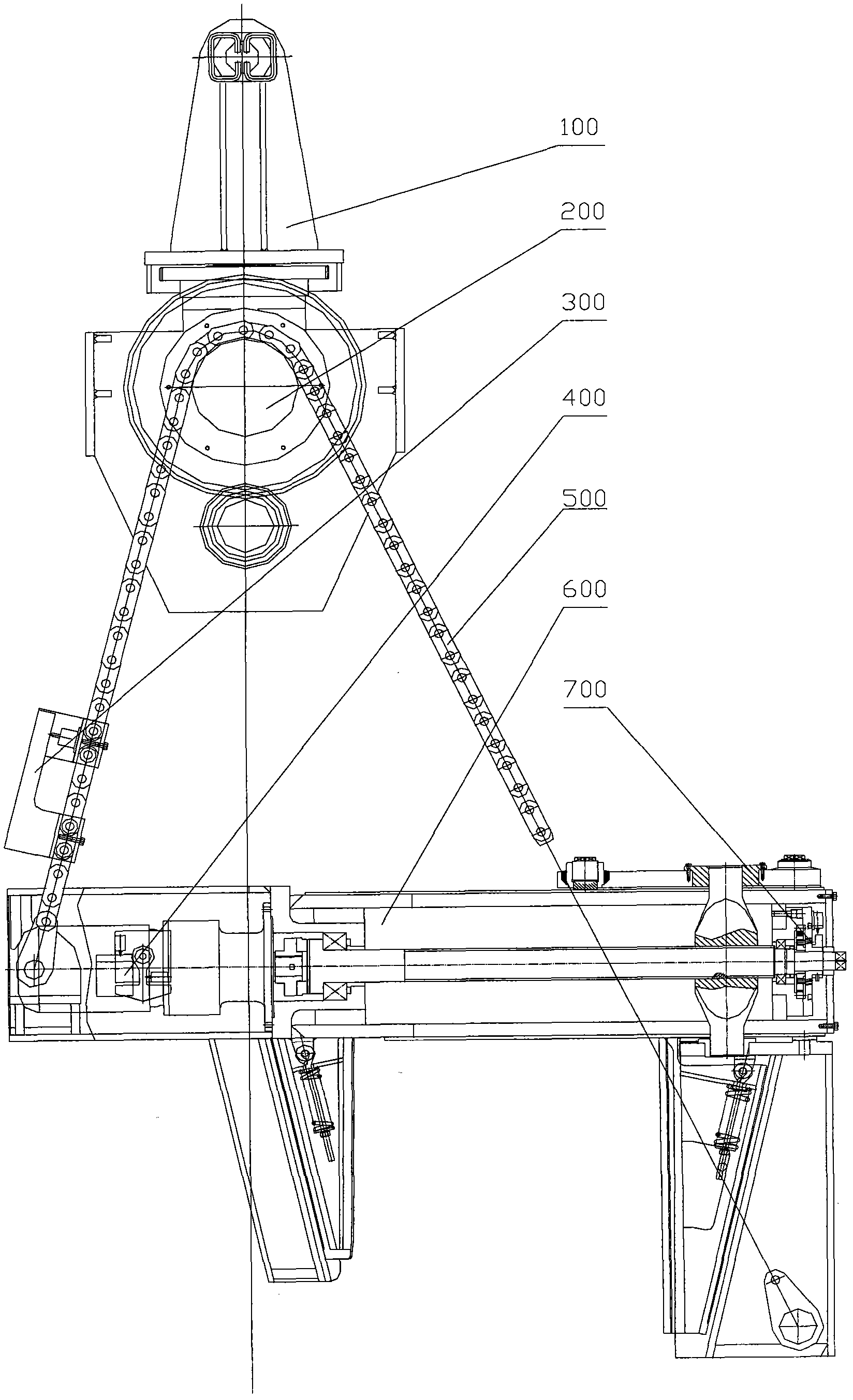

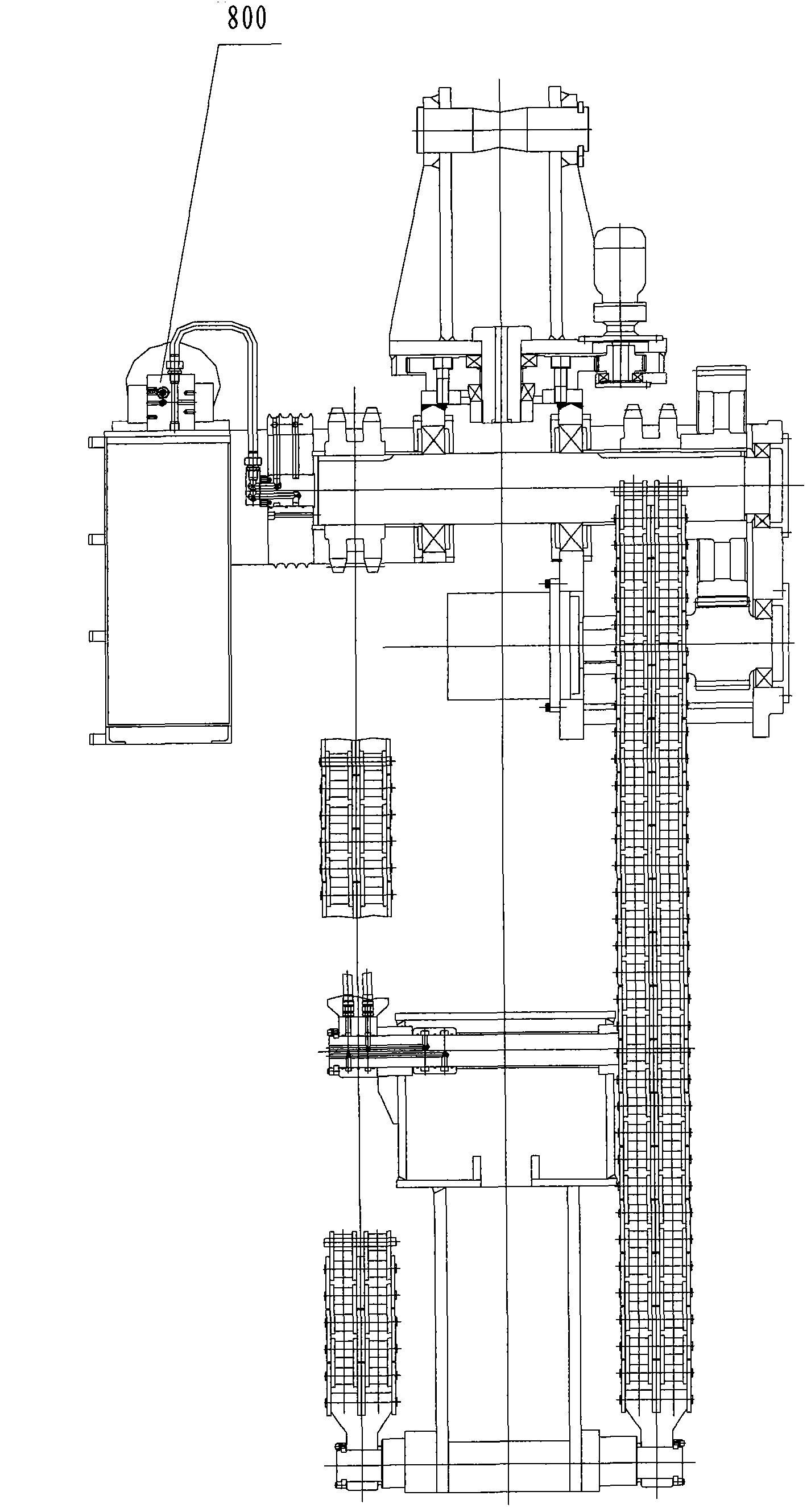

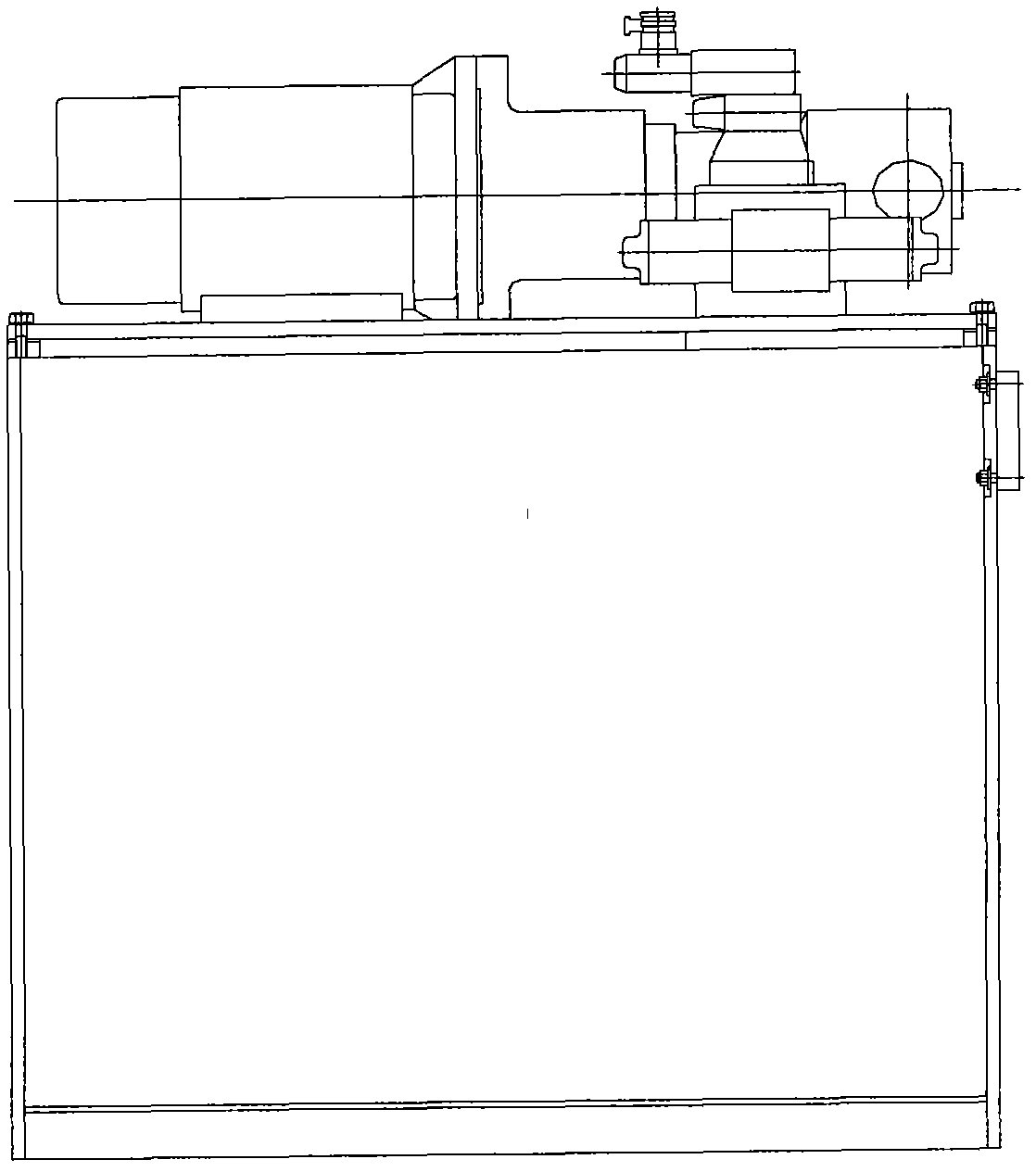

[0027] Clamp overall, such as figure 1 , 2 , as shown in 3:

[0028] hydraulic flip clamp see figure 1 , consisting of a horizontal rotating part 100, a flipping part 200, a clamping part 600, a control part composed of a safety switch 300, a flipping stroke control device 400, and a clamping stroke control device 700, a chain assembly 500 connecting the flipping part and the clamping part, and The hydraulic part 800 is composed. figure 2 is the side view of the clamp, image 3 This is the external view of the clamp hydraulic system.

[0029] Flip parts, such as Figure 4 , 5 Shown:

[0030] The turning part is composed of a hydraulic motor and a reducer 1, a pinion shaft 2, a sprocket 3, a chain 4, a main shaft 5, a large gear 6 and a turning body 7. The hydraulic motor and reducer 1 are directly assembled with the pinion shaft, installed on the lower part of the overturning body 7 through bearings, the large gear 6, and two sprockets 3 are installed on the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com