Glass preform drawing apparatus

A technology of stretching device and preform, which is applied in glass forming, glass reshaping, glass production, etc., to achieve the effect of device simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

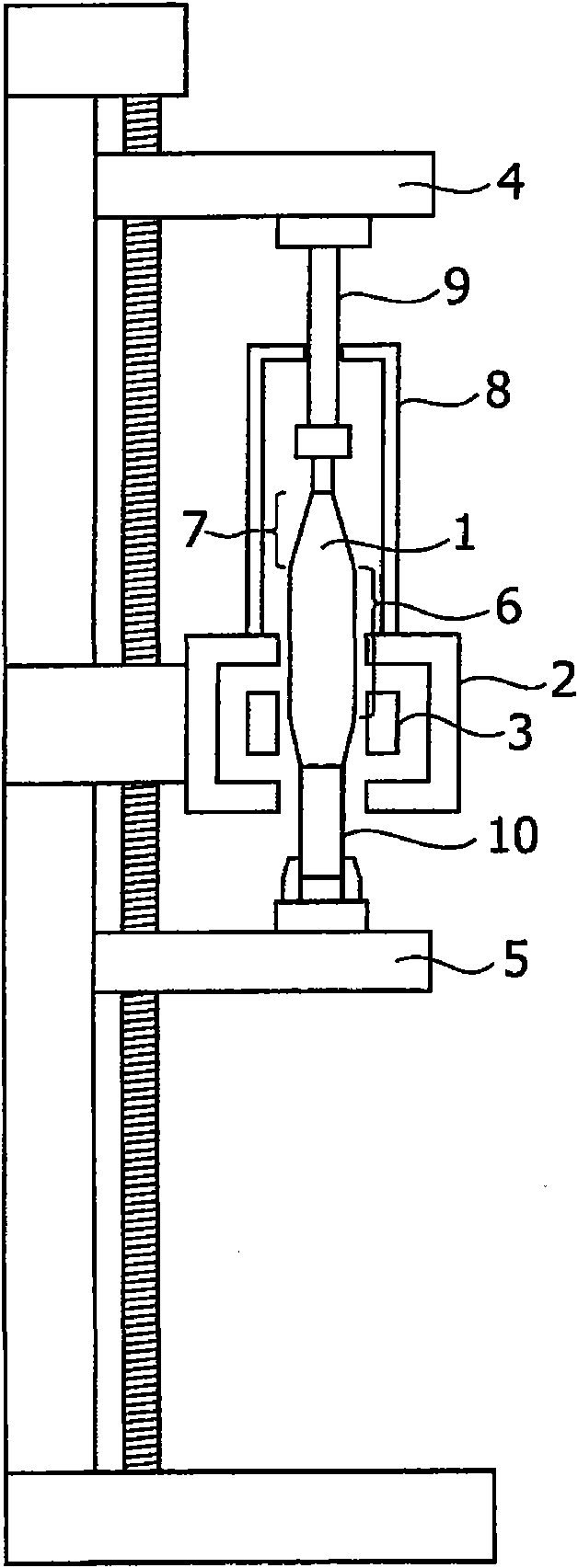

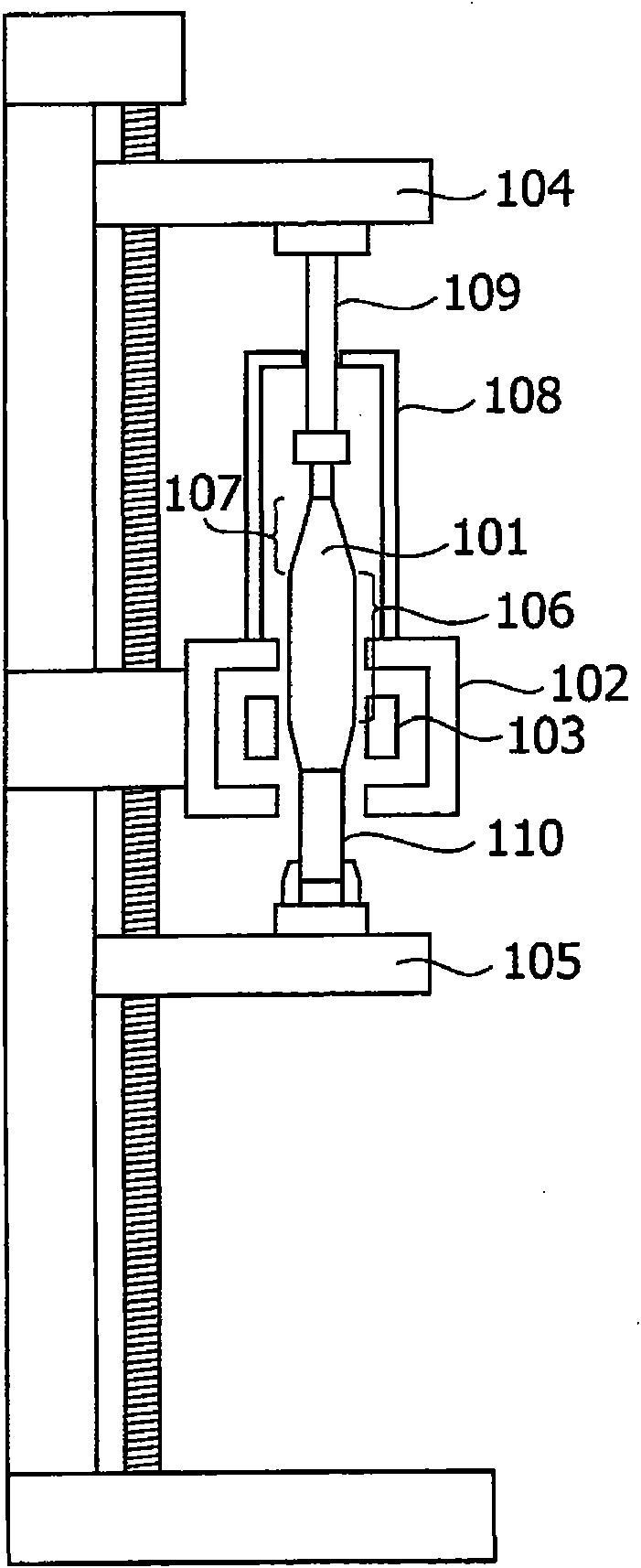

[0037] use figure 1In the shown device, the glass preform 1 for the optical fiber preform is stretched to a target outer diameter d=120mm. The glass preform 1 includes an effective portion having an average outer diameter of 170.5 mm, a length of 1000 mm, and tapered portions of approximately 300 mm at both ends of the effective portion. The material of the top chamber 8 is quartz glass. In the stretching step, the inside of the heating furnace 2 was kept under a nitrogen atmosphere at a temperature of 2300K.

[0038] Determine the stretching conditions according to the following formula:

[0039] V 2 =V 1 ×(D / d) 2

[0040] Among them, V 1 is the feeding speed of the glass preform (V 1 =10mm / min); V 2 is the extraction speed of the glass rod; D is the outer diameter of the stretched part of the glass preform.

[0041] In the glass rod obtained by stretching the effective portion of the glass preform, the maximum outer diameter near the end of stretching was 120.8mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com