Multi-flange dissimilar metal structure connection method

A technology of dissimilar metals and connection methods, which is applied in the direction of flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of flange weld tearing, metal flange thickness and rigidity, and difficulty in compression, etc. To achieve the effect of ensuring potential insulation, ensuring airtightness, watertightness and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

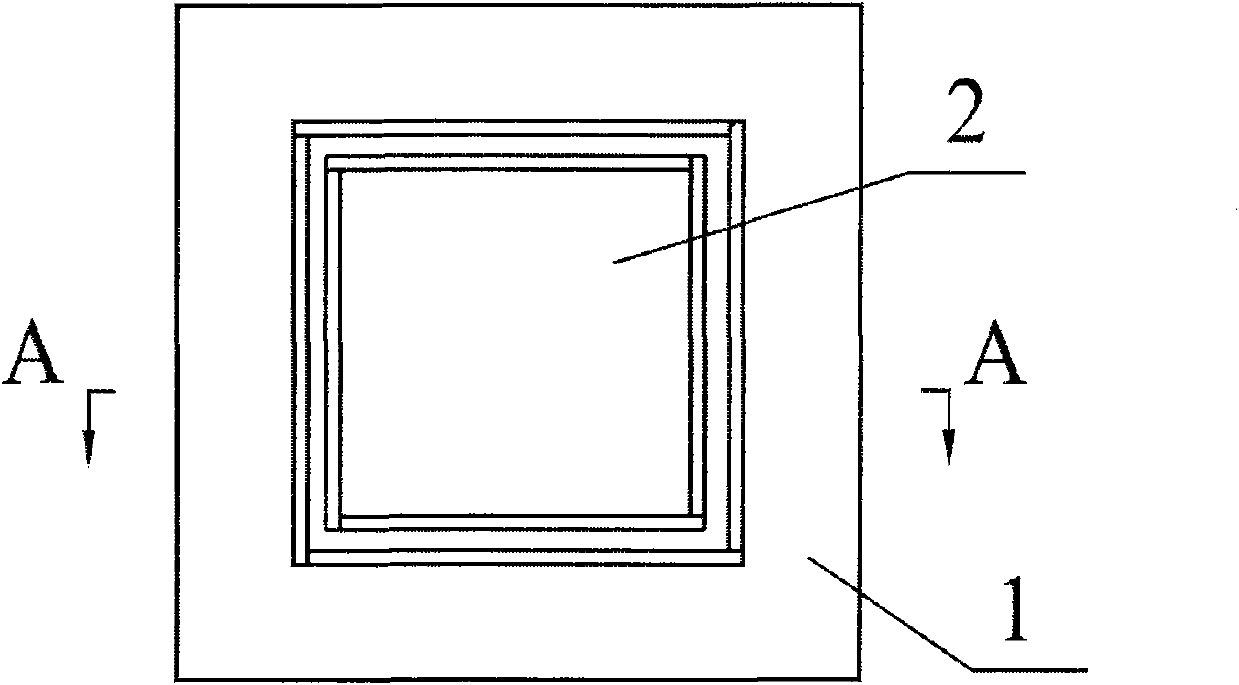

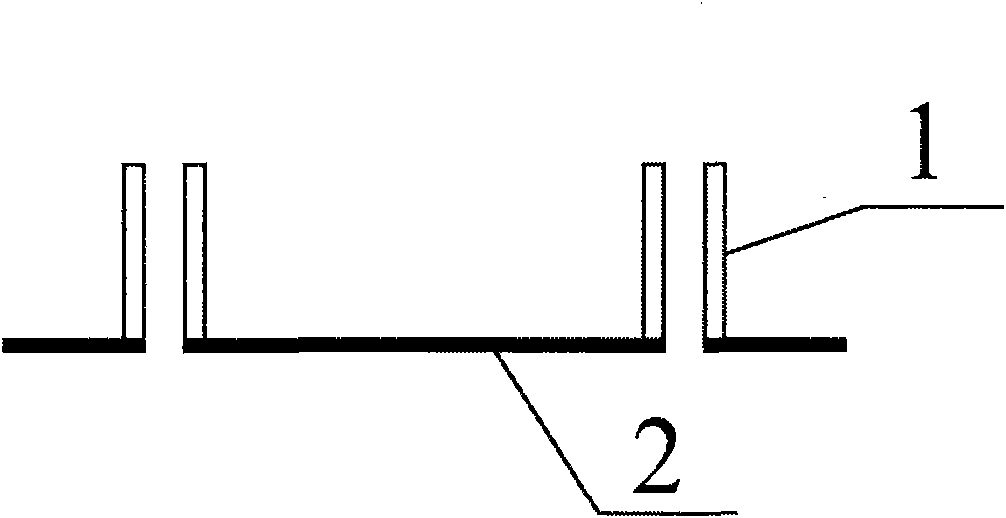

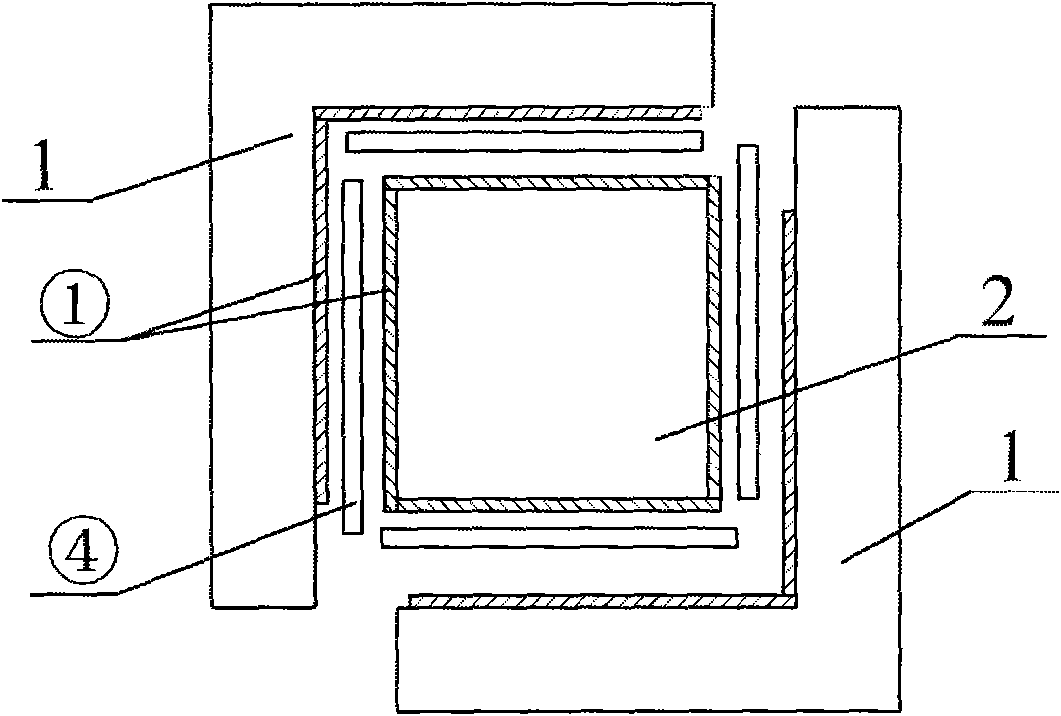

[0026] Such as image 3 Shown: Assembled connection of the outer steel structure 1 with four flanges and the inner titanium alloy structure 2. The peripheral structure 1 is decomposed into two parts for manufacture and assembly, each with two connecting flanges. The structural plate thickness of structural part 1 is 6mm, and the structural plate thickness of structural part 2 is 4mm. Drill screw holes uniformly on the connecting flange ① to ensure that the connecting positions match.

[0027] Such as Figure 4 and Figure 5 Shown: the disassembled structural part 1 is connected with the inner surrounding structural part 2 through M12 bolt assembly ②. Apply a 15mm insulating soft elastic cushion ④ between the connecting flanges ①, and use a cutting tool to make holes at the corresponding screw holes. Place insulating resin sleeves ③ with a thickness of 4mm at the screw holes of the connecting flanges ① of structural parts 1 and 2, and tighten the bolt assembly ② through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com