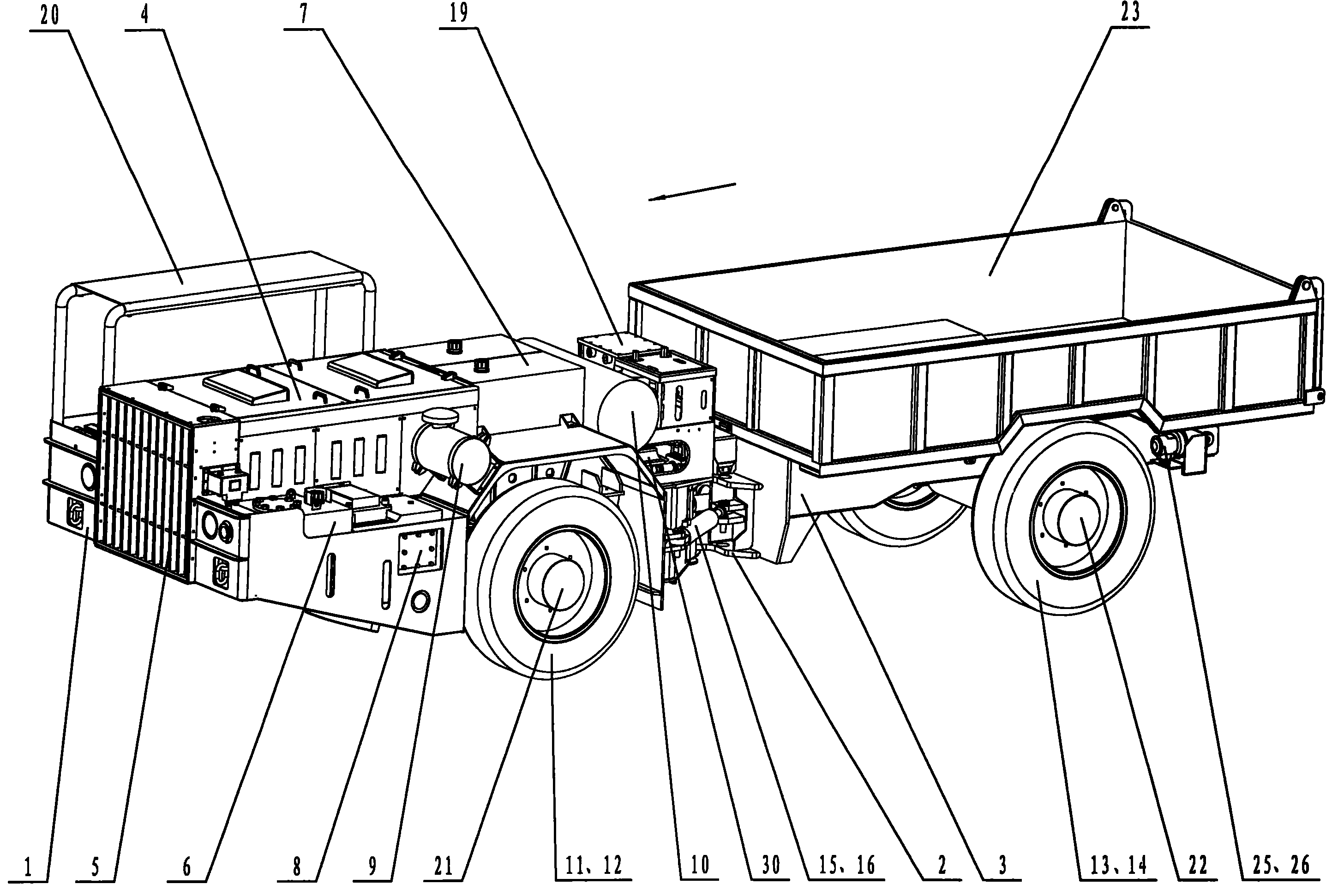

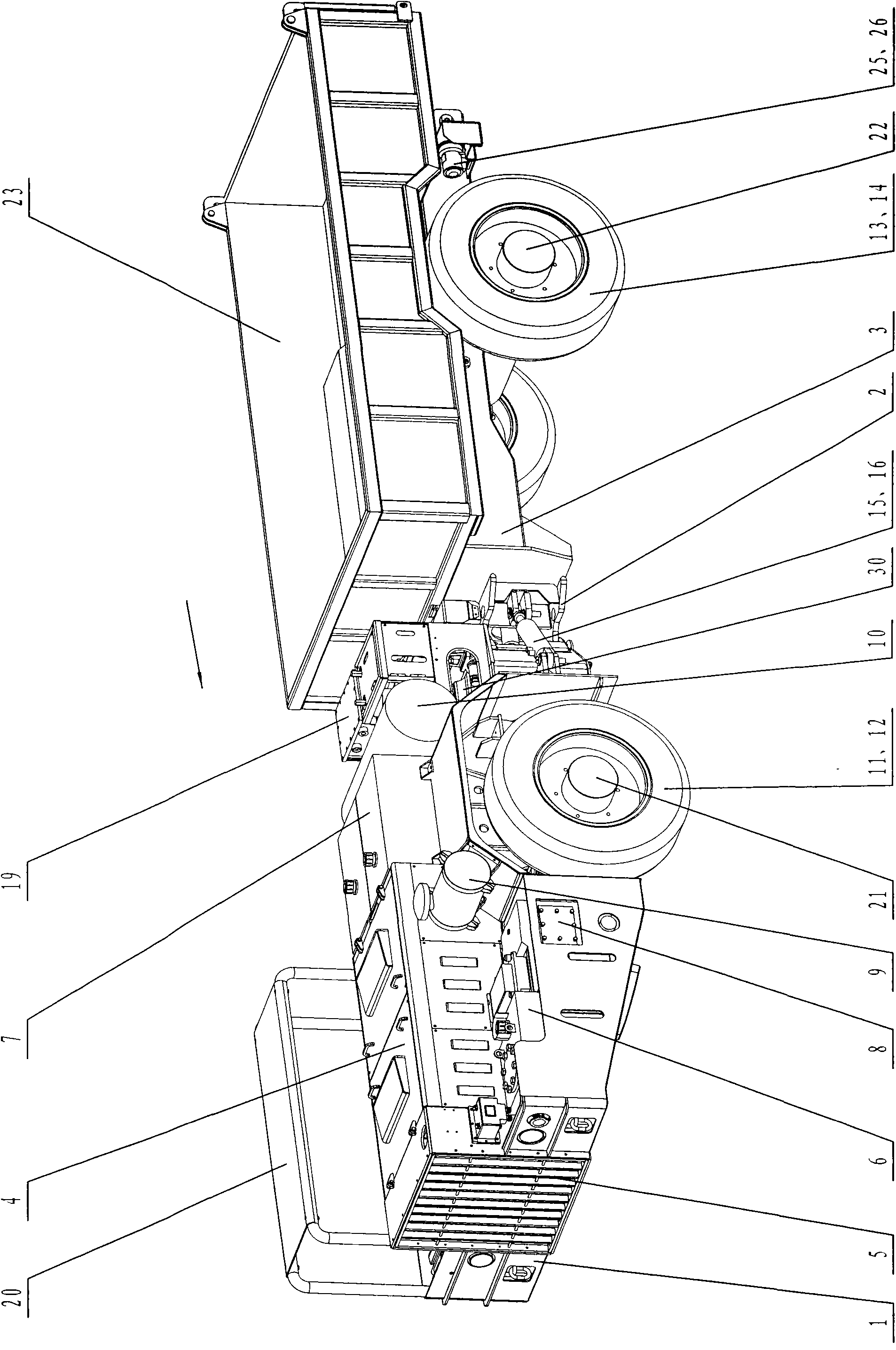

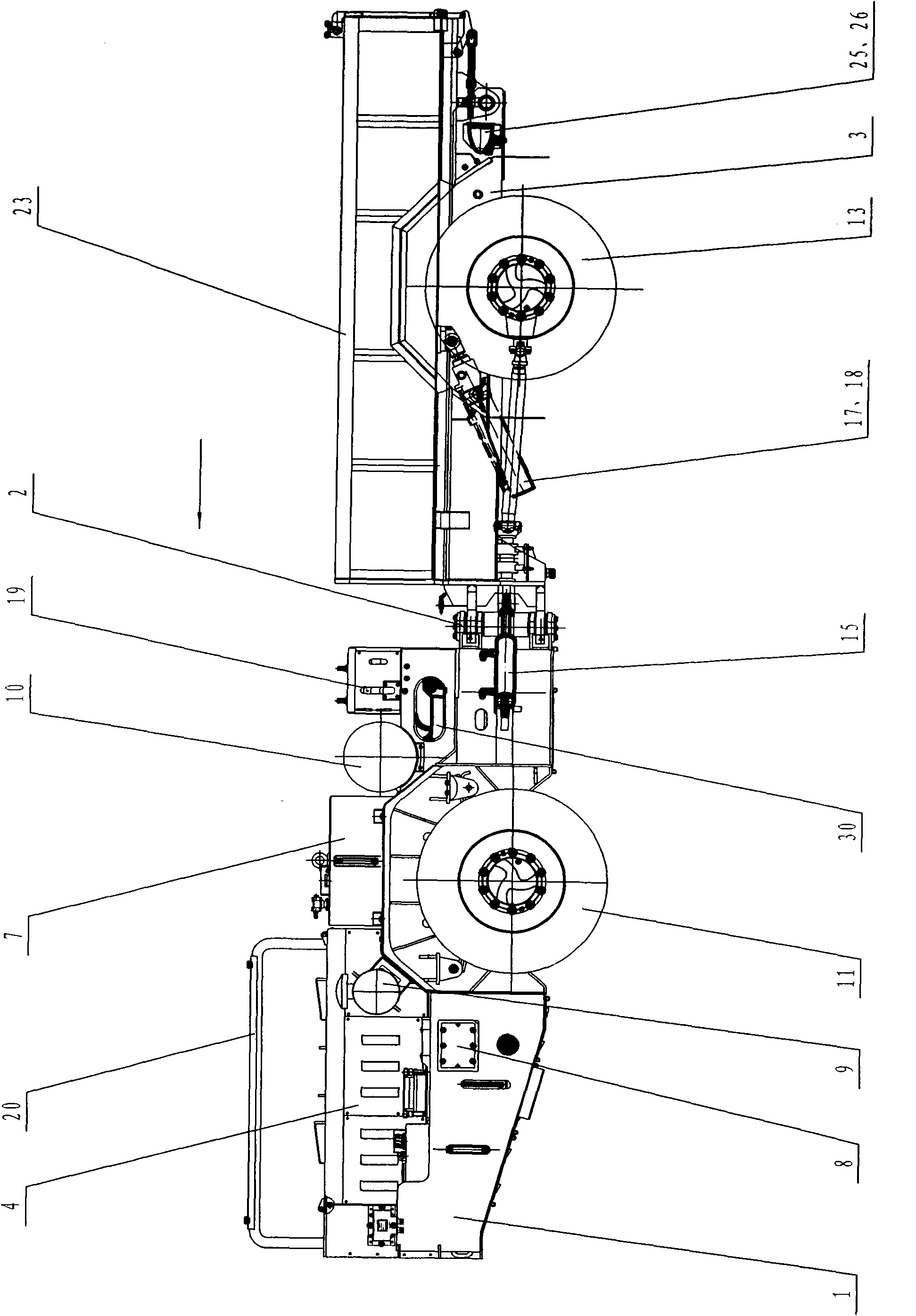

Articulated rubber wheel transport vehicle

A transporter, articulated technology, applied in the direction of transportation and packaging, tilt-bearing vehicles, vehicle parts, etc., can solve the problems of small volume, poor stability, and small dumping angle of the dump truck.

Inactive Publication Date: 2011-06-15

TAIYUAN INST OF COAL SCI RES INST +1

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the increasing degree of mechanized coal mining, the load capacity of transport vehicles is increasing, and the technical requirements for transport vehicles are getting higher and higher. Most of the ordinary rubber-tyred transport vehicles currently used have a low tonnage, only 2-3 tons. The volume of the dump truck is small, the tilt angle is small, and the stability is poor, so it is not suitable for long-distance transportation of concrete and bulk materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an articulated rubber wheel transport vehicle, which mainly comprises a front frame, a rear frame, a hinged frame, a diesel engine, a waste gas treatment box, a radiator, an air filter, a diesel tank, a hydraulic oil tank, a gas tank, front wheels, rear wheels, a drive axle, a torque converter, a speed changer, a hub reduction gear, a steering cylinder, a lifting cylinder, a cab, an operating mechanism, a shift reversing device and a self-unloading carriage. The vehicle is in articulated integral design, is in bidirectional driving, steers through the hydraulic oil tank and lifts and self-unloads; the diesel engine is in anti-explosion arrangement; the drive axle is in a self-locking, limited slip and speed differential mode; and the front and rear wheels are respectively provided with the hub reduction gear. The transport vehicle is advanced and reasonable in design, compact in structure, safe, stable and reliable, has a large back-turning self-unloading angle of 45 degrees, high in power, high in capacity and suitable for long-distance transport, and is an advanced articulated rubber wheel transport vehicle in a coal mine.

Description

Articulated rubber wheeled transport vehicle technical field The invention relates to an articulated rubber-tyred transport vehicle, which belongs to the technical field of underground auxiliary transport equipment in coal mines. Background technique A variety of auxiliary transport vehicles are used in coal mines, and rubber-tyred transport vehicles are the most common one. Due to the harsh environment and undulating ground in coal mines, explosion-proof design is required. Due to the increasing degree of mechanized coal mining, the load capacity of transport vehicles is increasing, and the technical requirements for transport vehicles are getting higher and higher. Most of the ordinary rubber-tyred transport vehicles currently used have a low tonnage, only 2-3 tons. The volume of the dump truck is small, the tilt angle is small, and the stability is poor, so it is not suitable for long-distance transportation of concrete and bulk materials. Contents of the invention ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60P1/04B60P1/28B60K5/00B60K17/28B60K17/06B60K20/02B62D5/06

Inventor 赵海兴张学荣王金喜谢龙王清雨马建民郭培燕王斌杨振声赵瑞萍赵秀梅陈永峰王庆祥石涛王帆

Owner TAIYUAN INST OF COAL SCI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com